This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

Sludge Screen

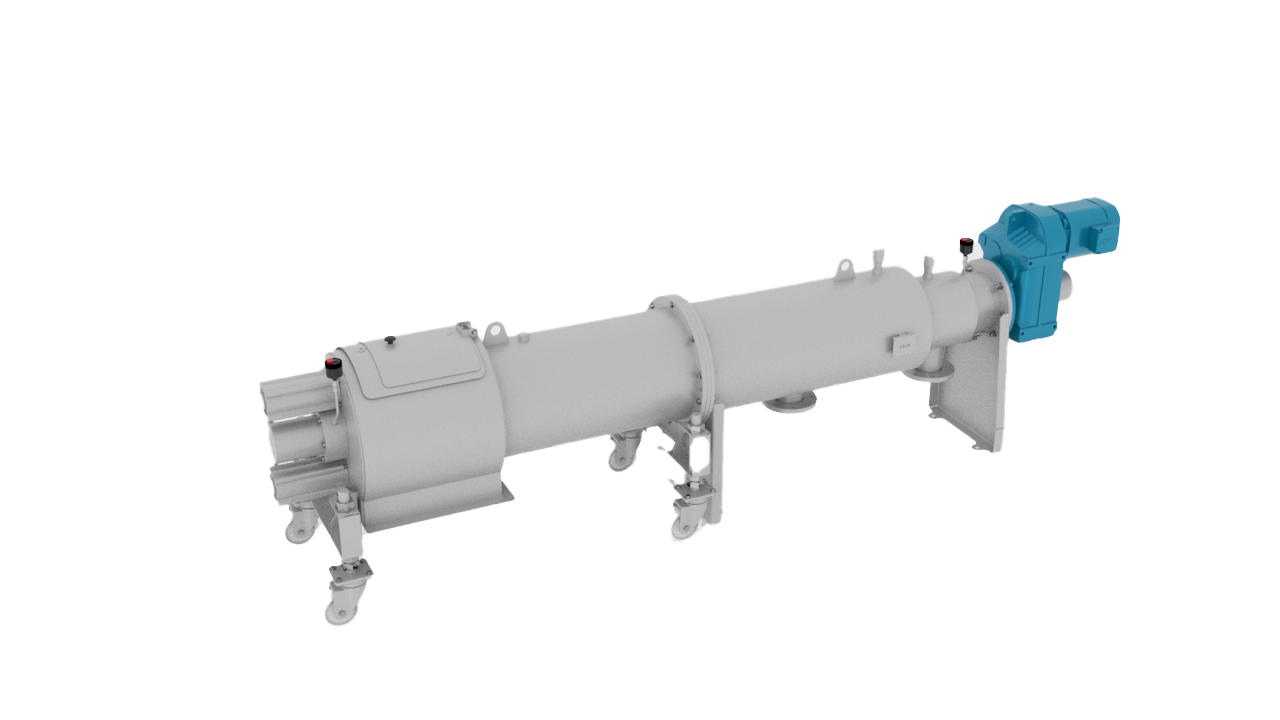

SLUDGE SCREEN

Fibrous materials, hair, wet wipes, plastics, and other substances in the wastewater lead to considerable malfunctions in the area of sludge treatment, making difficult the normal development of the process. These can be removed by a mechanical sieving, avoiding malfunctions in pumps, clogging of pipes or accumulation of solids in the digestion.

The sludge screen consists of a cylindrical, enclosed tube that is used to separate solids from primary and secondary sludges of up to 1% dry substance content.

Features and structure

The sludge screen consists of a cylindrical, enclosed tube that has a screen with a screw inside it. The system is mainly made up by three functional areas: screening zone, compression/dewatering zone and discharge zone.

Vía an inlet flange, the liquid to be screened is added into the screen under pressure. The machine may thus also be embedded into the pipework.

Substances that are larger than the perforation are held back in the screen, removed with a screw conveyor from its surface and conveyed into the dewatering and compressing area. There, a back pressure cone provides for the necessary back pressure to achieve the required total solid content. The functioning of the cone is regulated by pneumatic cylinders.

The screw conveyor conveys the screenings continuously in the direction of disposal and thus displaces the back pressure cone.

In the disposal area, the dewatered and compressed screenings fall from the machine into a container as part of the existing setup.

Operation

Options in assembly and maintenance

ADVANTAGES OF SLUDGE SCREEN

- High throughputs due to pressurized screening

- Could be used for highly viscous sludge’s or those containing grease

- High level of dewatering of the screening by counter pressure cone

- If the screw has become worn, this can be readjusted

- Reinforced coils reduce wear, particularly when used with abrasive media

- Increase in operational safety

- Minimum maintenance required

- Effective cleaning of the screening surface without additional industrial water.

- Machine completely hygienic with odor encapsulation

USES OF SLUDGE SCREEN

Public utility and industrial sewage plants

- Process water screening

- Sludge screening/ secondary sludge

- Sludge screening/ primary sludge

Paper and cellulose industry

- Process water screening

Other industries

- Process water screening in textile industry

- Composting plants in waste disposal systems – leachate treatment

OTHER EQUIPMENT

Related equipment