This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

INDUSTRIAL WATERS

ABOUT INDUSTRIAL WATERS

Industrial wastewaters are those discharged by factories as a result of processes of manufacturing, production, transformation, consumption, cleaning or maintenance operations.

Irrespective of whether these industrial waters are returned to nature or discharged into the main drains, they need to be treated. In both cases, the composition of the wastewater is required to comply with all the physical and chemical parameters laid down by law, and no discharges are permitted that have an environmental impact on the medium receiving them. When the quality of the post-treatment water is high enough, industrial waters may be reused.

SPECIFICATIONS OF INDUSTRIAL WATERS

Industrial wastewaters vary greatly in terms of composition and flow, and the physicochemical characteristics of the effluents produced are as different as the industries originating them.

They are more contaminated than domestic wastewaters and may contain very different types of pollutants that are highly toxic and difficult to remove.

Contamination of industrial waters

The contamination from industrial activities may have different origins:

- Pollution caused by the harvesting of raw materials, including the environmental damage from the mining and transportation of the non-renewable raw materials and recycled ones required in manufacturing.

- Pollution due to the process, arising both during it and as a by-product.

- Pollution due to the product; this includes environmental damage caused by its everyday use.

- Collateral pollution, which includes a product’s final disposal at the end of its useful life.

Discharges are not made continuously or on a regular basis. Depending on the type of production and the industrial process, there will be a greater tendency to make discharges at certain times throughout the day or during the year.

CHARACTERISTICS OF THE DISCHARGES ACCORDING TO DIFFERENT INDUSTRIAL ACTIVITIES

The following is a more detailed description of the most common industrial activities with a higher level of deployment that contribute to the discharge of industrial waters:

Metalworking and chemical industry

- Metalworking industry: these kinds of processes tend to produce the remains of oils and greases, detergents, metals, acids, and basic substances. These discharges are scarcely biodegradable and have a high potential toxicity for drainage systems.

- Petrochemical and refining industry: they record highly variable flows, and the contamination is related to spillages. The effluents are highly contaminated by hydrocarbons, with high concentration of BOD, COB, toxicity, solids in suspension, heavy metal, oils, greases, etc.

- Fine chemical and pharmaceutical industry: the contaminants are produced by different chemical reactions, product washing, and the cleaning of installations and containers. The following are some of the most common contaminants: organic matter, soluble salts, phosphorous, ammonia and nitrogen, oils and greases, phenols, and heavy metals.

Agricultural, healthcare and textile industries

- Agroindustrial sector: this encompasses all those effluents from livestock farming and agriculture. The main contaminants are organic matter, fertilisers and pesticides. They may contaminate wells and underground aquifers, as well as rivers, seas and reservoirs.

- Healthcare centres and hospitals: the nature of the discharge, although slightly more concentrated, is similar to domestic wastewater. Large hospitals may be one of the activities that discharge the highest flow into the drains.

- Textile industry: its wastewater has an acid or alkaline pH, a low content of materials in suspension, nitrogenated compounds, and a high content of soluble organic matter.

Manufacture of chemical products

- Manufacture of detergents: these are characterised by a large number of solids in suspension and colloidal material, oils and greases, detergents, and organic matter, which means high BOD, COB and toxicity.

- Manufacture of paints and varnishes: these discharges are highly contaminating, being characterised by very high conductivity and toxicity.

- Manufacture of pesticides: this contamination involves the use of certain organochlorine, organophosphate, organonitrogen and organometallic compounds. It may require 3000 litres of cleaning water per tonne of product. The waste is characterised by high concentrations of COD, TOC, toxicity, and high conductivities.

IMPORTANCE OF TREATING INDUSTRIAL EFFLUENTS

Over 80% of the wastewaters generated by industrial activities today are discharged into the environment without any kind of treatment. This seriously reduces the quality of the water in rivers, seas, and reservoirs, harming ecosystems and affecting myriad species.

New legislative policies in environmental matters call for the redesign of industrial processes in order to minimise water consumption and maximise its recovery, with contaminated industrial waters being treated prior to their discharge.

SOLUTION FOR TREATING INDUSTRIAL WATERS

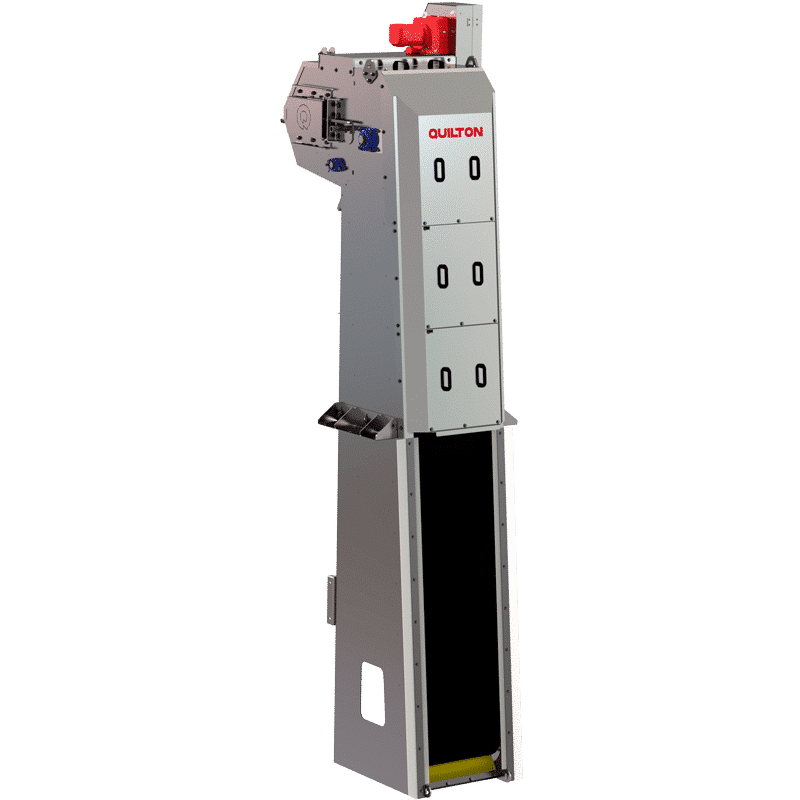

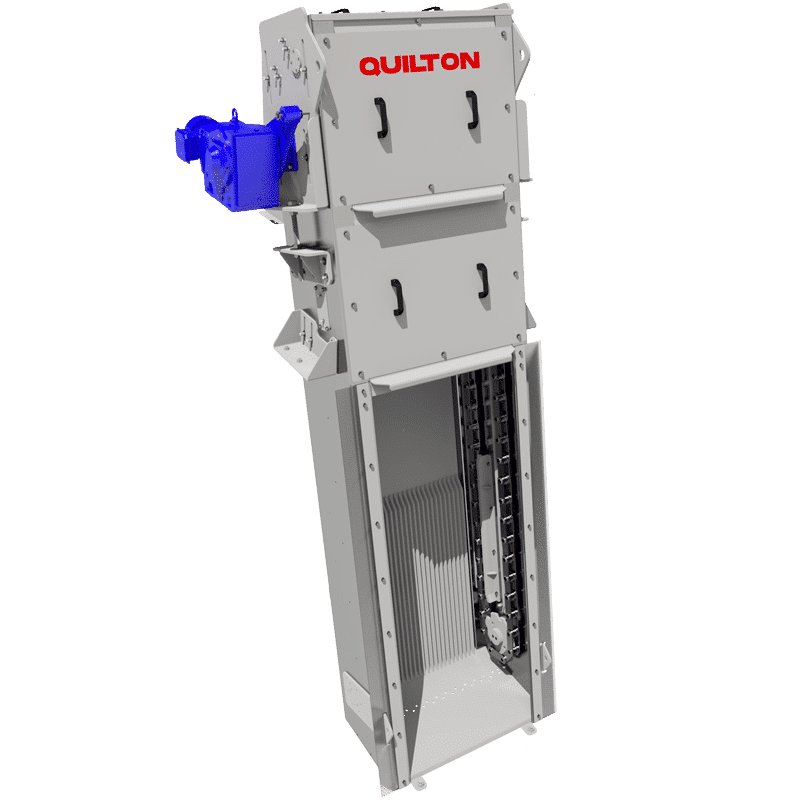

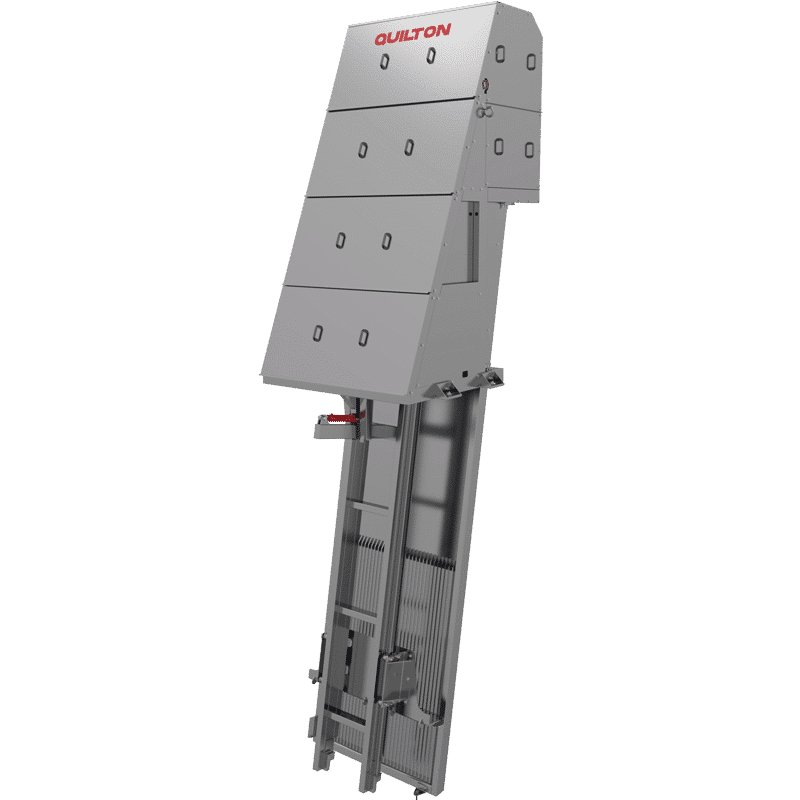

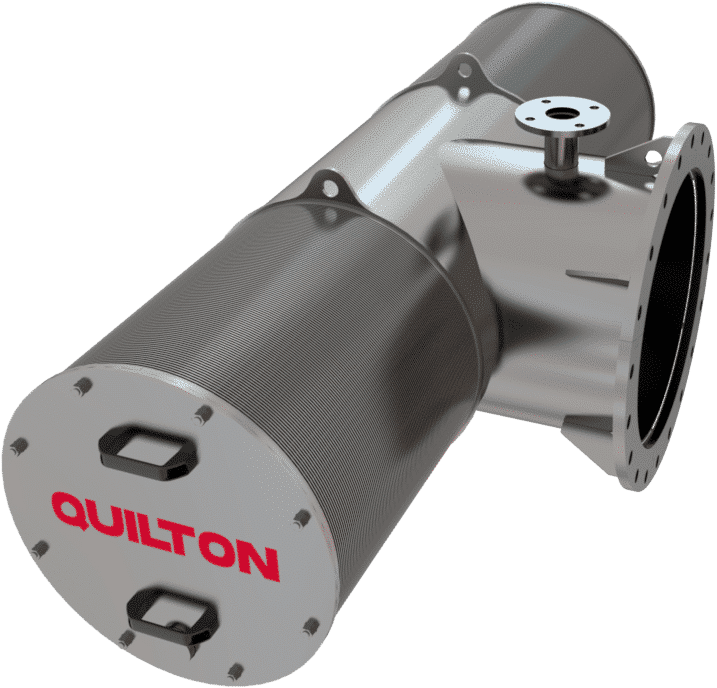

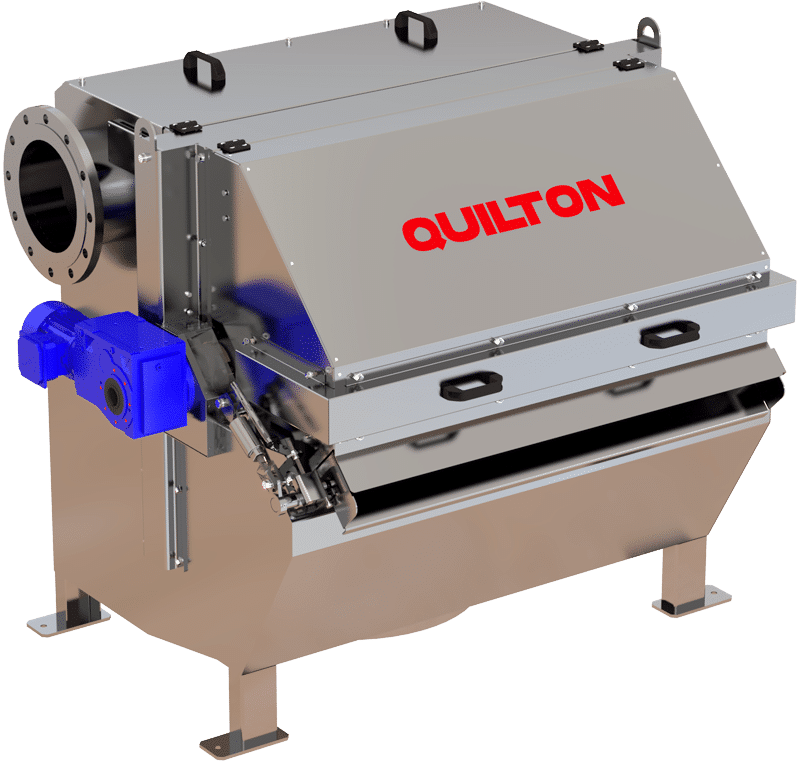

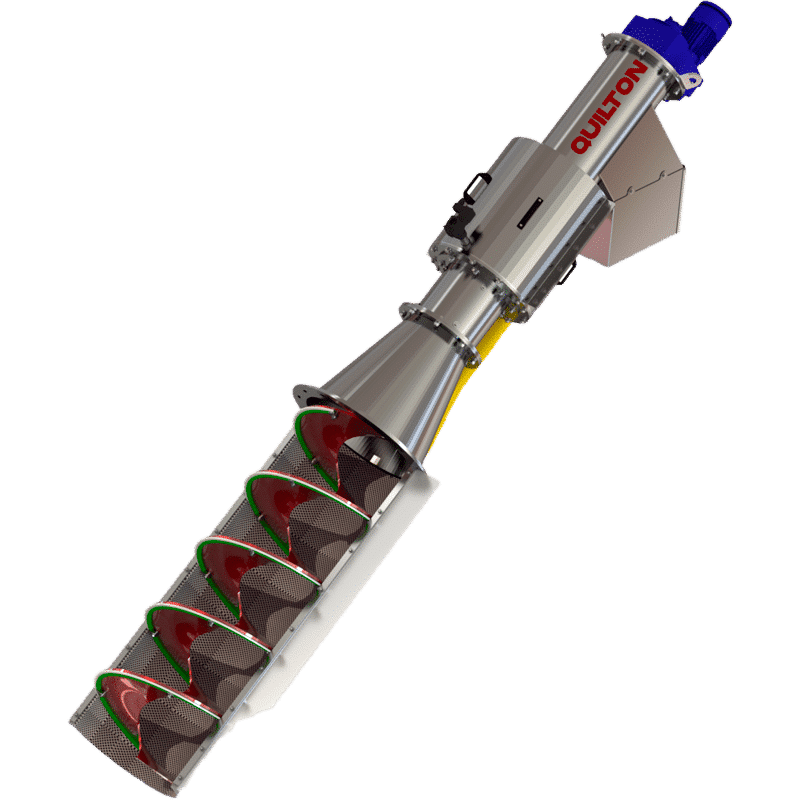

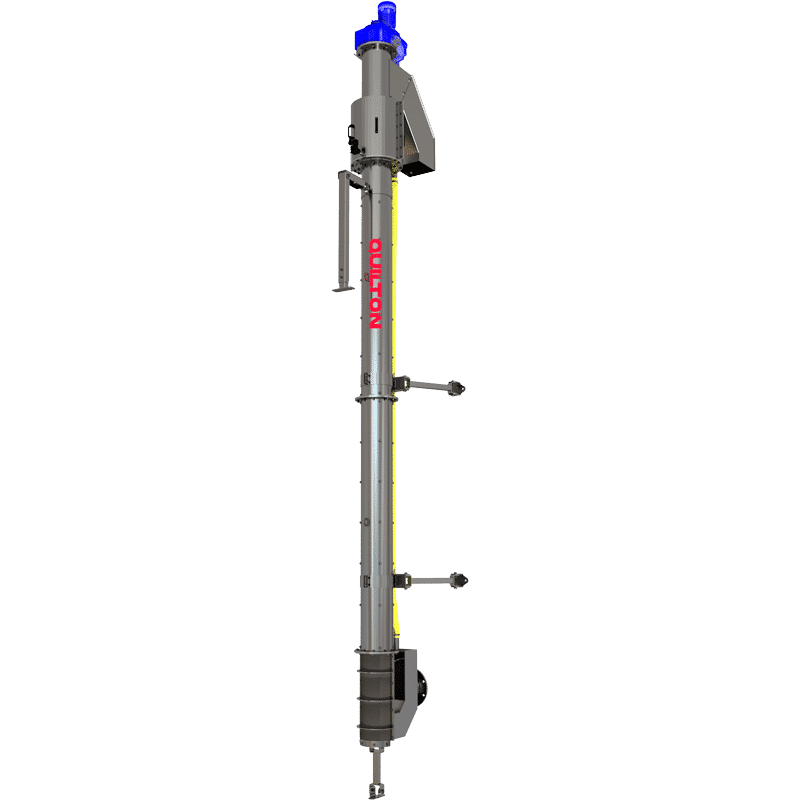

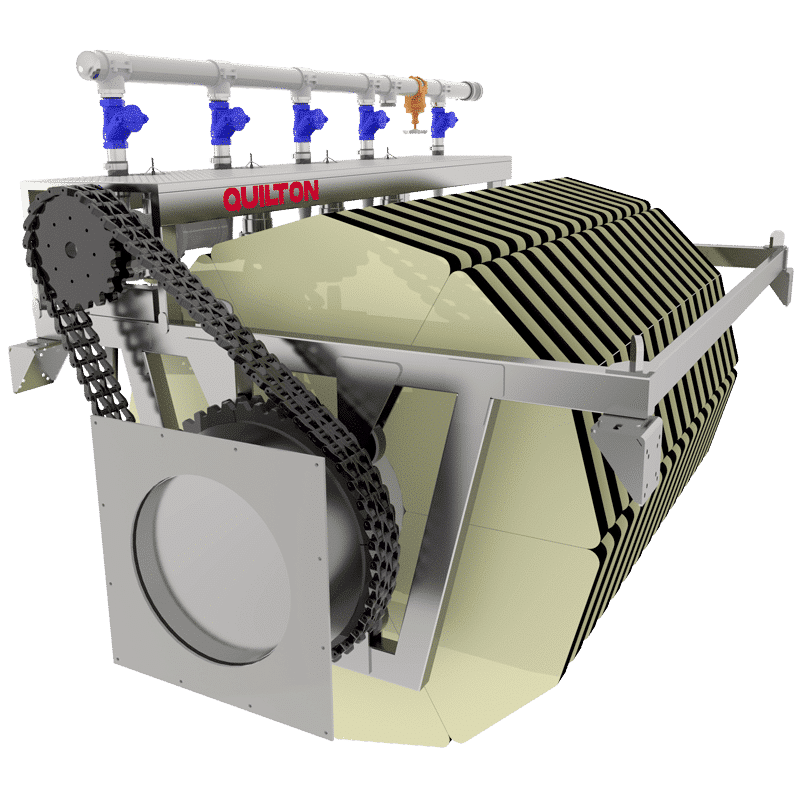

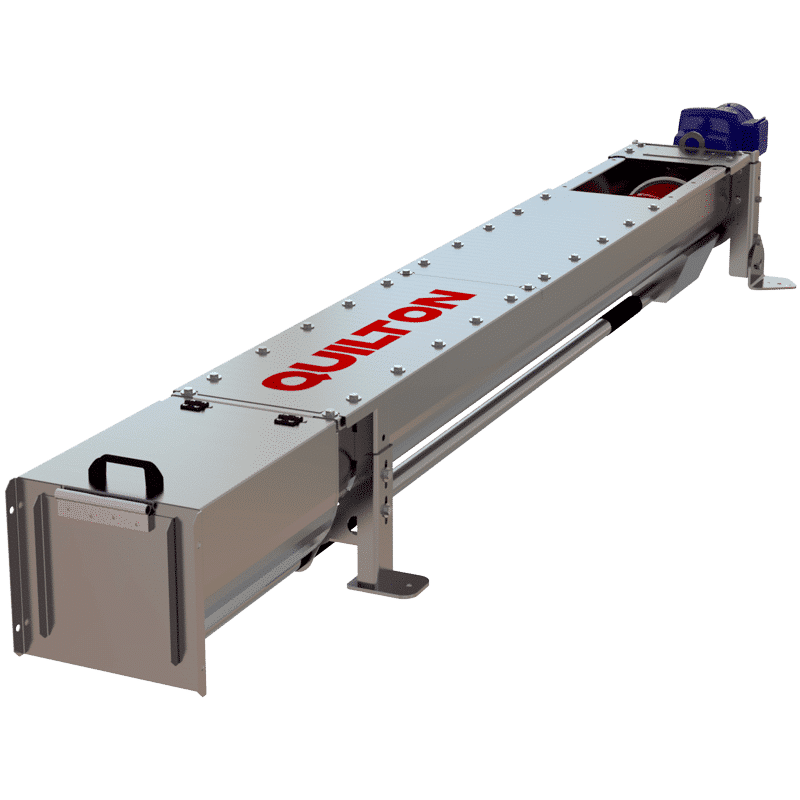

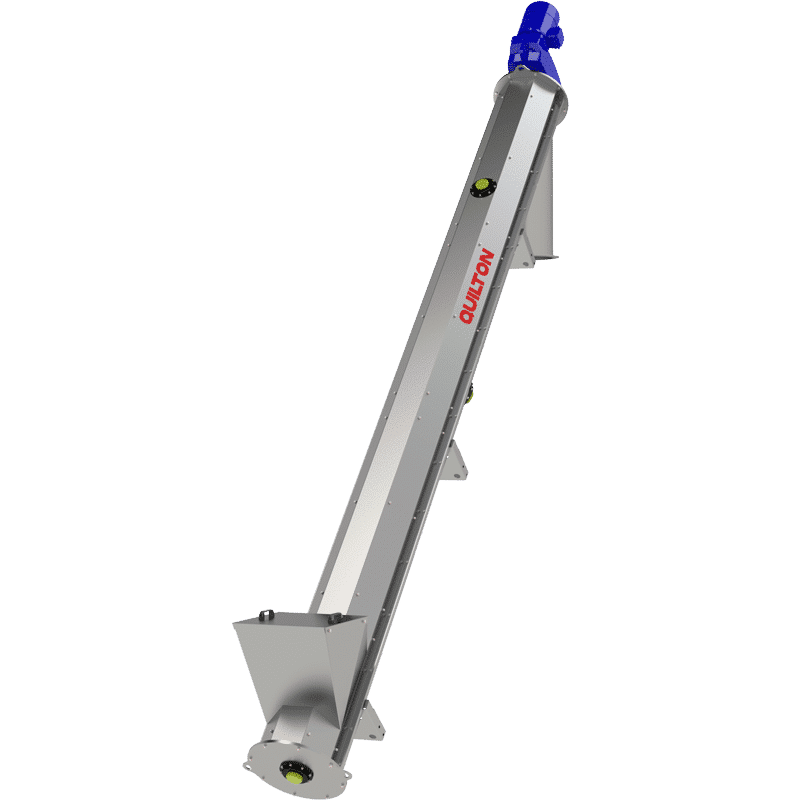

With a view to attaining new quality and treatment standards for industrial waters, the technology available has been developed to perform screening processes. QUILTON provides solutions suited to the processing needs of industrial wastewaters.