This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

Compact plants

Prior to the actual treatment process itself, raw waters generally undergo a pre-treatment that involves a series of physical and mechanical steps designed to decant from the wastewater the largest possible amount of materials whose nature or size would cause problems in subsequent treatment processes.

The problems associated with the deficient quality of the raw water (septicity, large variations in flow and/or load, industrial effluents, etc.) inform the need for the pre-treatment to include other mechanical or chemical steps designed to improve the quality of those waters to ensure a better performance by downstream processes or avoid environmental issues. The use of a compact plant in small premises may be the most versatile solution, and significantly reduce the building work required.

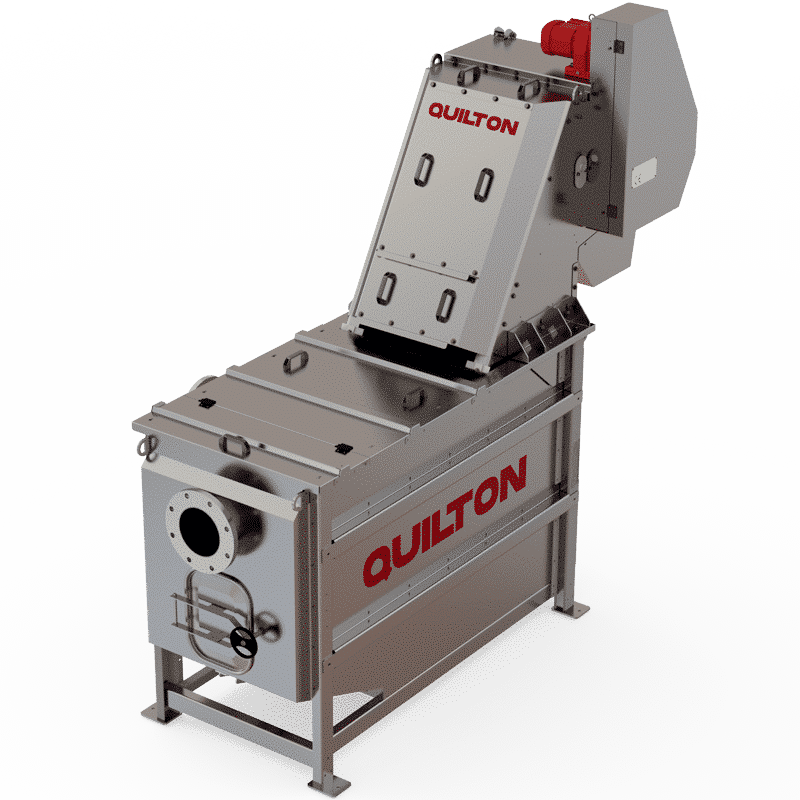

QUILTON COMPACT TREATMENTS

Other product families

Mostrando 3 resultados

IMPORTANCE OF PRE-TREATMENT

It is vital to give pre-treatment the importance it deserves, focusing on its design and operation, as any shortcomings may have a negative impact on all the other installations, leading to clogged pipes and pumps, wear on equipment, the build-up of scaling and sand deposits in anaerobic digesters, and the impaired performance of the various processes, for example.

Pre-treatment operations are generally designed to remove the most visible and troublesome part of the pollution from an operating perspective, large and medium-sized solids, grit, fats, greases and oils, etc., usually producing moderate amounts of waste that can be readily handled and stored.

The following are the processes normally involved in pre-treatment:

- Roughing with thick bar screens.

- Roughing with fine screens.

- Desanding.

- Uniformity and regulation of flows and loads.

- Preaeration.

COMPACT PLANTS

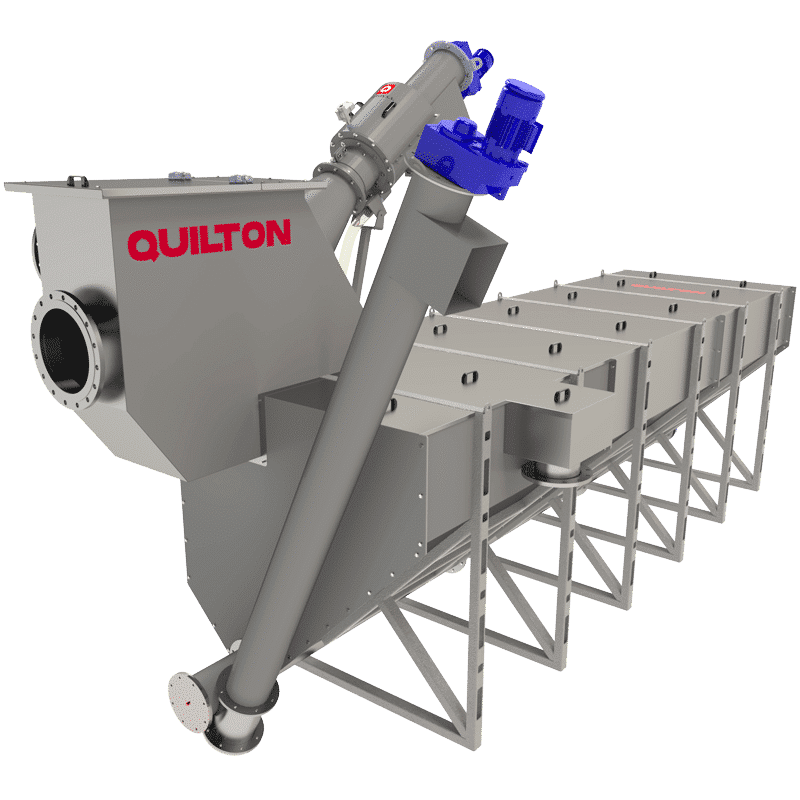

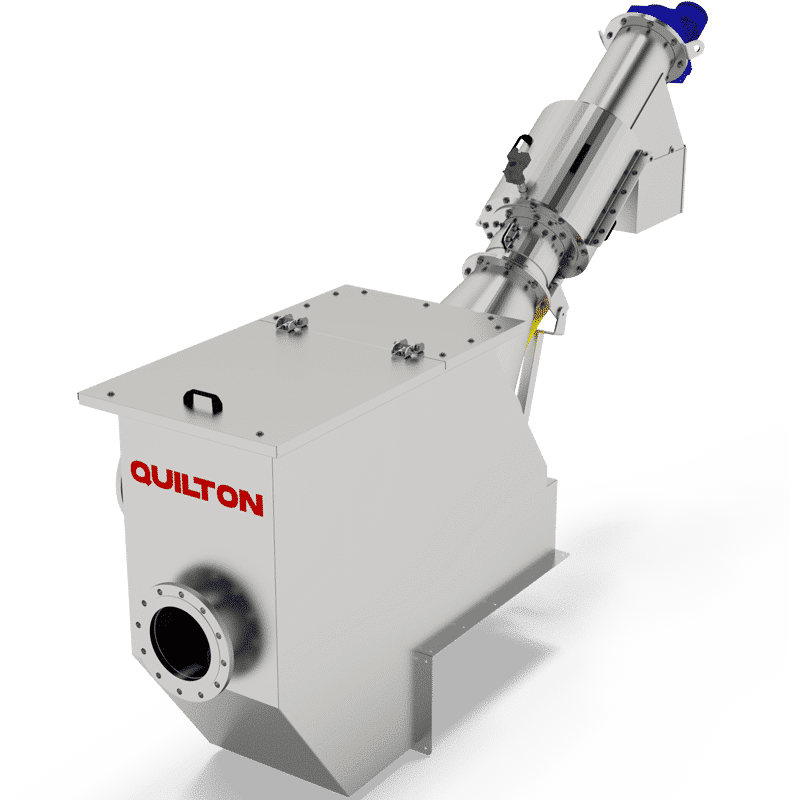

Compact plants involve a series of compressed processes, reducing the building work that is usually required in traditional treatments.

The small size of these plants is ideal for these solution in which a reduced area can group several processes.

QUILTON responds to this need with a range of solutions according to the different challenges to be resolved and each plant’s characteristics, such as the following:

- Preteatment compact plants.

- Self-cleaning band screen compact plants.

- Comprehensive roughing stations.

- Clamshell bucket solid receiving stations.

- Compact plants for treating slurry.

ADVANTAGE OF A SELF-CLEANING BAND SCREEN COMPACT PLANT

The following are the main advantages of a QUILTON self-cleaning band screen compact plant:

- Less building works.

- Bespoke designs.

- Possibility of deploying mobile units.

- Turnkey delivery.

- Flexibility catering for different treatments, flows and solid concentrations.

APPLICATIONS OF COMPACT PLANTS

QUILTON compact plants have different uses, such as the following:

- Pre-treatment in small treatment plants.

- Extension of existing pre-treatment processes.

- Multiple uses in industry.