This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

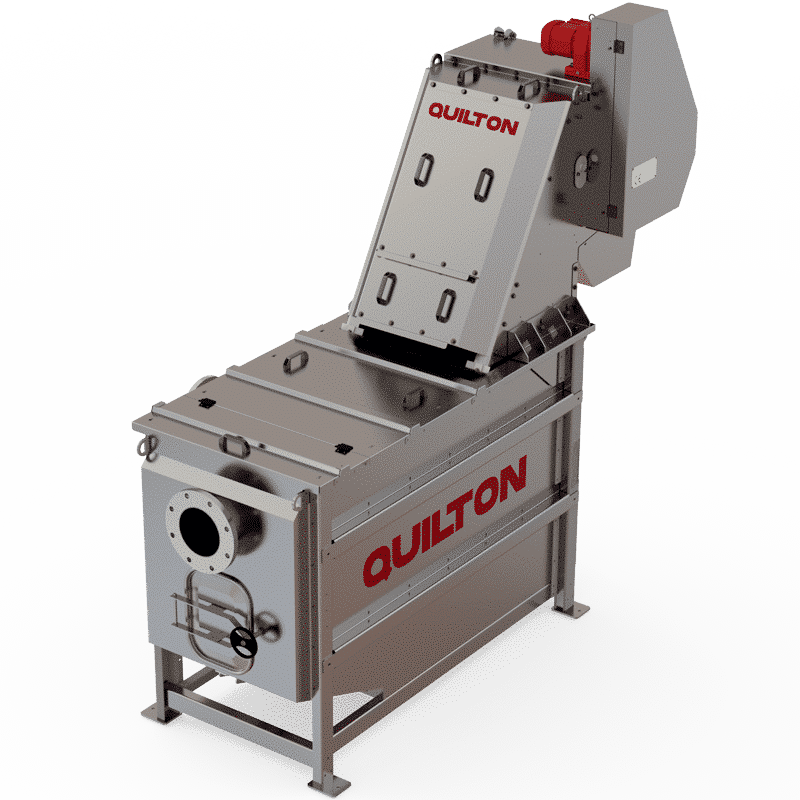

Pretreatment compact plant

Compact

Prior to the actual treatment process itself, raw waters generally undergo a pre-treatment that involves a series of physical and mechanical steps designed to decant from the wastewater the largest possible amount of materials whose nature or size would cause problems in subsequent treatment processes.

The problems associated with the deficient quality of the raw water (septicity, large variations in flow and/or load, industrial discharges, etc.) inform the need for the pre-treatment to include other mechanical or chemical steps designed to improve the quality of those waters to ensure a better performance by downstream processes or avoid environmental issues.

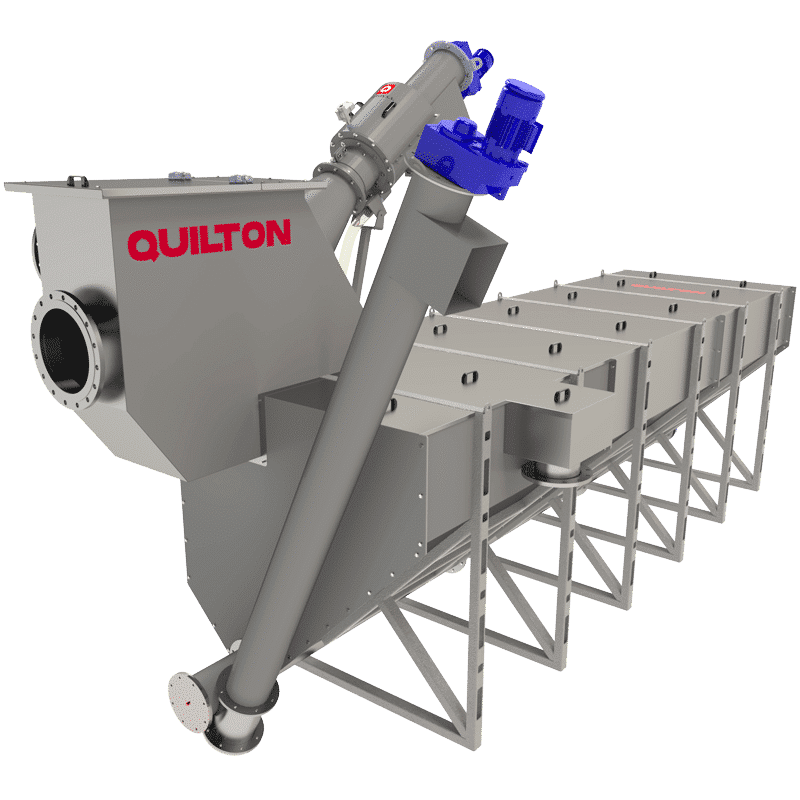

The use of a pretreatment compact plant in small premises may be the most versatile solution and significantly reduce the building work required.

Features and structure

A QUILTON pretreatment compact plant combines a high performance with very small space requirements.

Pretreatment compact plants have a modular design in order to cater for operations and processes involving different types of waters.

OPERATION

A QUILTON pretreatment compact plant includes the following operations:

- Screening.

- Sedimentation.

- Sand decantation.

- Preaeration.

- Removal of fats and floating particles.

DESIGN AND STRUCTURE

A QUILTON pretreatment compact plant has the following structural specifications:

- Screen spacing: 1 to 10 mm.

- Decanting 95% of sand particles ≥ 200-250 µm.

- Automated removal of fats and floating particles.

- Reduction in the amount of solids by up to 35%.

- Capacity of up to 210 l/s.

- Small space requirements.

- Modular design.

Operation

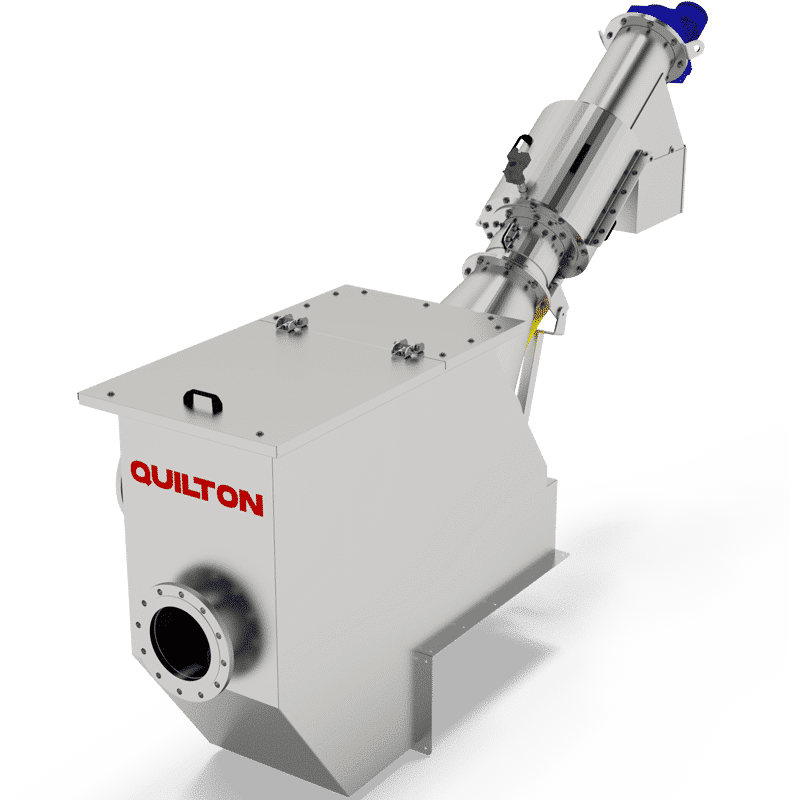

Wastewaters are pumped or flow into the compact plant through its inlet flange. The first step involves the roughing of solids, retaining those particles that are larger than the spacing of the bar screen in place. In this step, the water passes through the screen, with the roughing, extraction, and pre-compacting of the solids prior to their discharge. The spacing on the bar screens in this process tends to be 3-6 mm.

The second step involves the decanting of sands in a tub that acts as a desander. The retention and decanting times are calculated to draw off 95% of the sand particles ≥ 200-250 µm.

The grit is moved by a screw conveyor positioned lengthwise on the bottom, with another extractor screw that removes the sand for its subsequent discharge.

As a third and auxiliary process, a QUILTON compact plant has a fat, grease and oil catchment area with fine-bubble aeration that makes fats and other floating particles easier to remove.

Options in assembly and maintenance

ADVANTAGES OF A PRETREATMENT COMPACT PLANT

- Robust, shaftless auger, avoiding clogging and plugging even with fibrous products.

- Low revs.

- No internal bearings.

- Special long-life brushes.

- Scraper for fats and floating particles.

- Reduction in the amount of solids by up to 35%.

- Compact design.

- Ideal for floor installation, especially when space is limited; no building work required.

- Easy to assemble onsite.

- Low investment and maintenance costs.

OTHER EQUIPMENT

Related equipment