This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

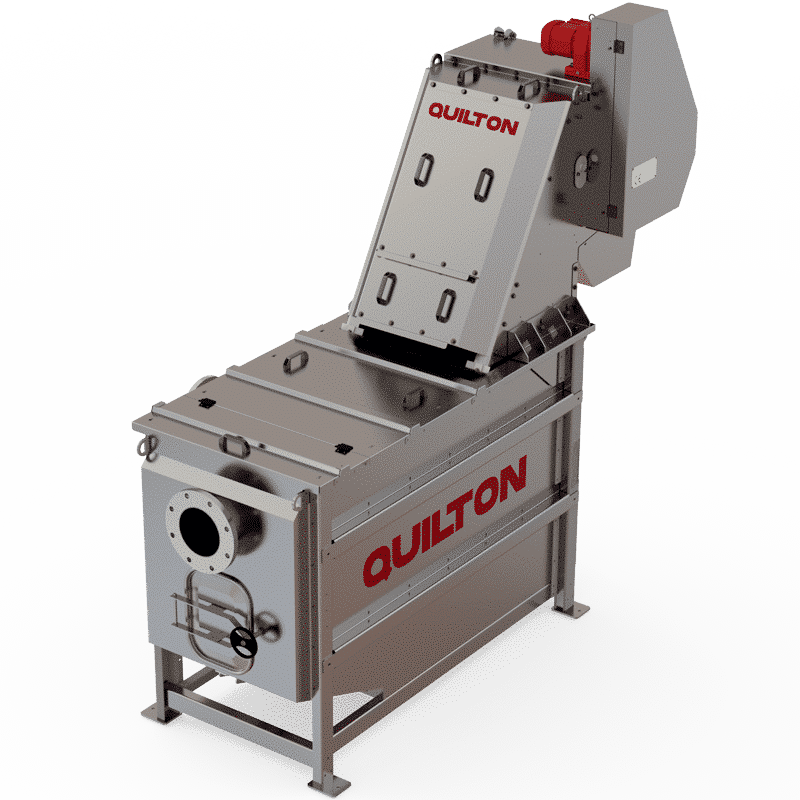

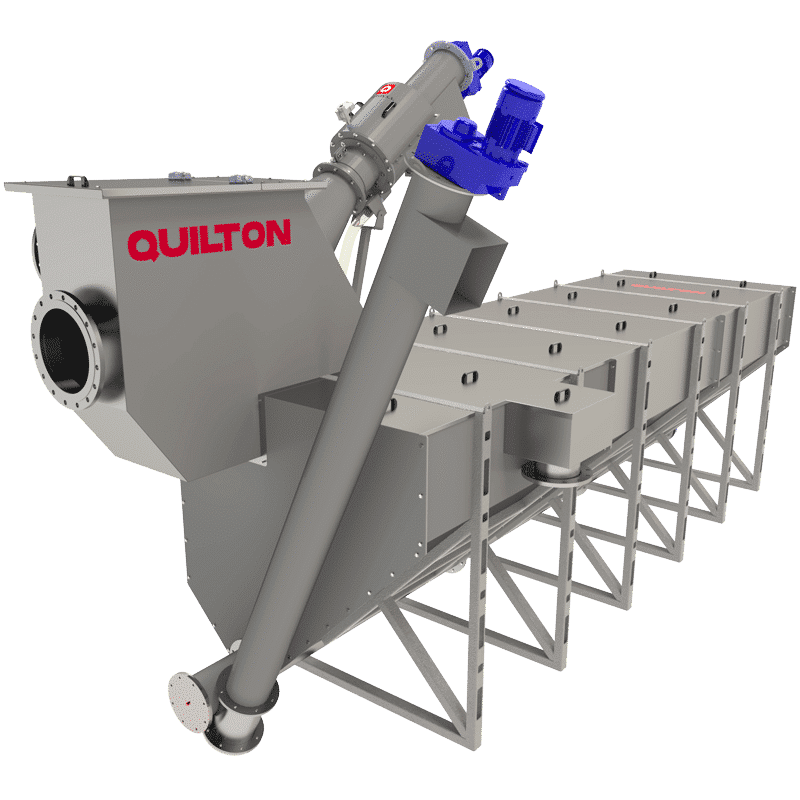

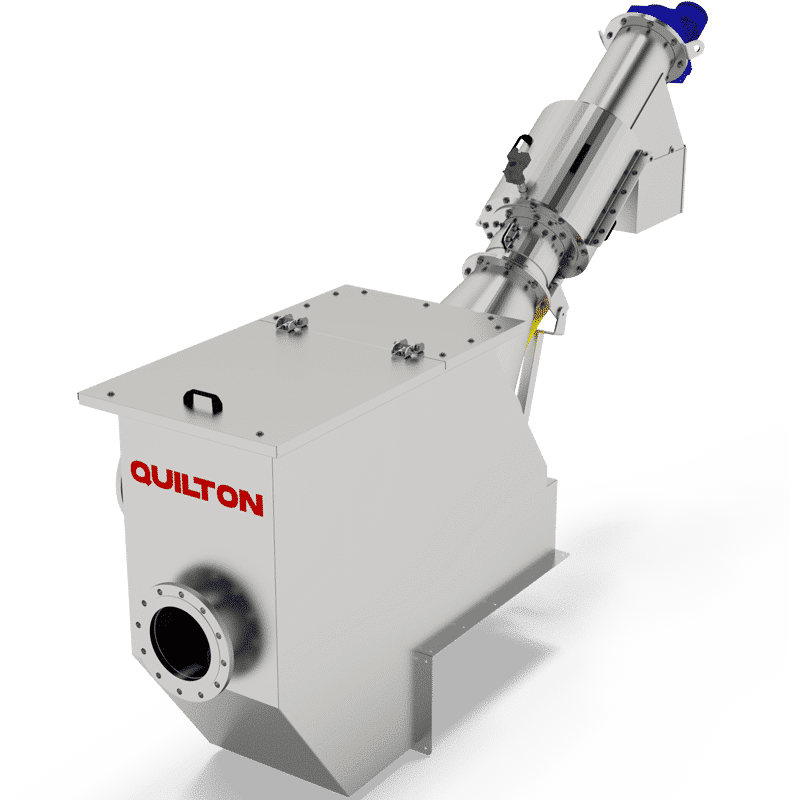

Screw screen compact plant

Compact

The design of the QUILTON screw screen combines a tub with a QUILTON screw screen, which allows for the use of a screw screen without the need for a trough, using flanged connections.

Thanks to this design, QUILTON has provided an effective and safe solution for customers with problems of space and without the possibility of installing a trough. This means avoiding the costs and all the drawbacks involved in a civil engineering project.

This is a multipurpose piece of equipment with a very broad and varied sphere of application: from operations at WWTPs for screening in the pre-treatment or treatment of sludges, to the removal of solids floating in the effluents from different types of industries.

Features and structure

A QUILTON screw screen compact plant has the following structural and mechanical specifications:

- 30-45º angle of positioning.

- No building works.

- Bespoke design.

- Possibility of deploying mobile units.

- Type of materials: stainless steels AISI-304, AISI-316, duplex 2205, super duplex 2507, etc.

- Fully automatic operation.

- Totally enclosed discharge trough.

- Bagging unit (optional) that avoids the emission of odours from compacted wastes.

- Completely hermetic from the screening area through to the discharge trough.

- Brush on the spiral for the self-cleaning of the screening area.

COMPONENTS OF THE SCREW SCREEN COMPACT PLANT

A QUILTON screw screen compact plant basically has the following five components:

- Tub: stainless-steel structure containing the screw screen and flanged inlet, outlet and spillover connections.

- Filtering area: this is the part of the screw screen that is connected to the tub and through which the wastewaters flow. It consists of a steel screening basket with perforations (3-10 mm in diameter) and a spiral on its lower end to provide continuous cleaning of the screening area.

- Waste transport or lifting area: this is the middle part between the filtering and discharge areas. It involves a tubular trough and a screw conveyor.

- Pre-compacting and compacting area: this is the last and highest part of the screw, and as its name indicates, it is the area where the screened solids are moved, washed and compacted by the extraction screw. It leads to the discharge trough.

- Operation: this involves a low-rev gear motor mounted on the top of the unit.

Operation

The station is flange-fed, and the wastewater flows to the screw screen. Lateral watertight gaskets provide the seal and fit with the tub and the water passes through the screen. Those solids larger than the spacing are retained while the water flows through the holes on the perforated sheet and filtering area on the screen.

The solids are retained in the screen’s filtering area, which is cleaned by a brush mounted on the spiral, which at the same time conveys the wastes retained in an upward direction and compacts them in its end zone.

As the solids are raised, they are dried and compacted before being offloaded into a skip. The liquid drained from the pressing is collected and returned to the screening basket through a flexible hose.

Options in assembly and maintenance

ADVANTAGES OF THE SCREW SCREEN

The following are the main advantages of a QUILTON screw screen:

- Simple and robust design.

- Straightforward to install.

- Suitable for small spaces.

- Minimal operating and maintenance costs.

- Low energy consumption.

- Readily adaptable to variable operating conditions.

- No additional cleaning systems.

- No building work.

- Possibility of deploying mobile units.

- Turnkey deliveries.

APPLICATIONS OF THE SCREW SCREEN COMPACT PLANT

A QUILTON screw screen compact plant has various applications, such as the following:

- Extension of existing pre-treatment processes.

- Auxiliary treatments.

- Multiple uses in industry.

OTHER EQUIPMENT

Related equipment