This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

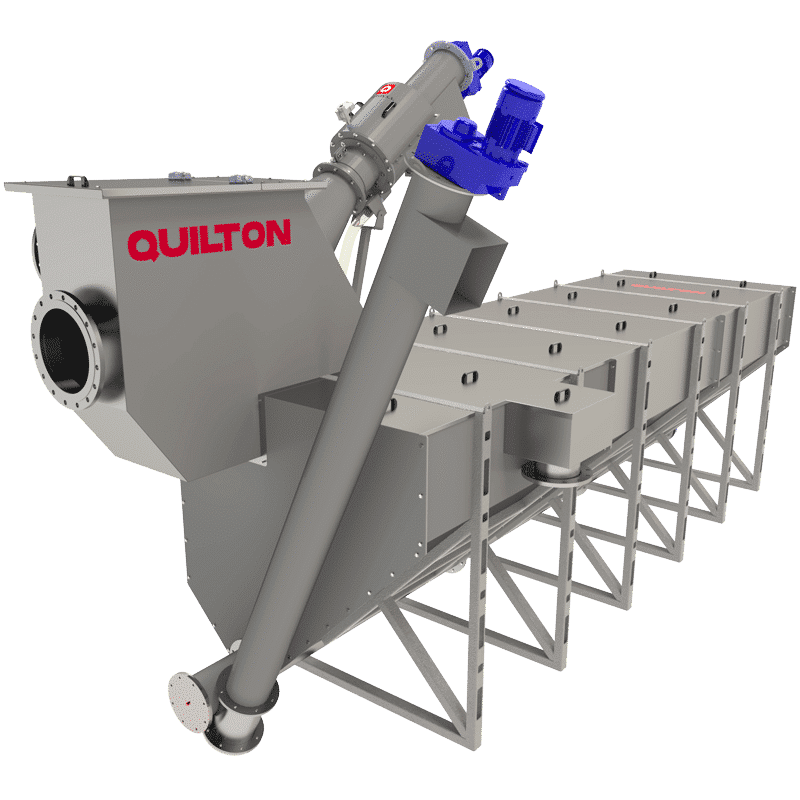

Self-cleaning band screen compact plant

Compact

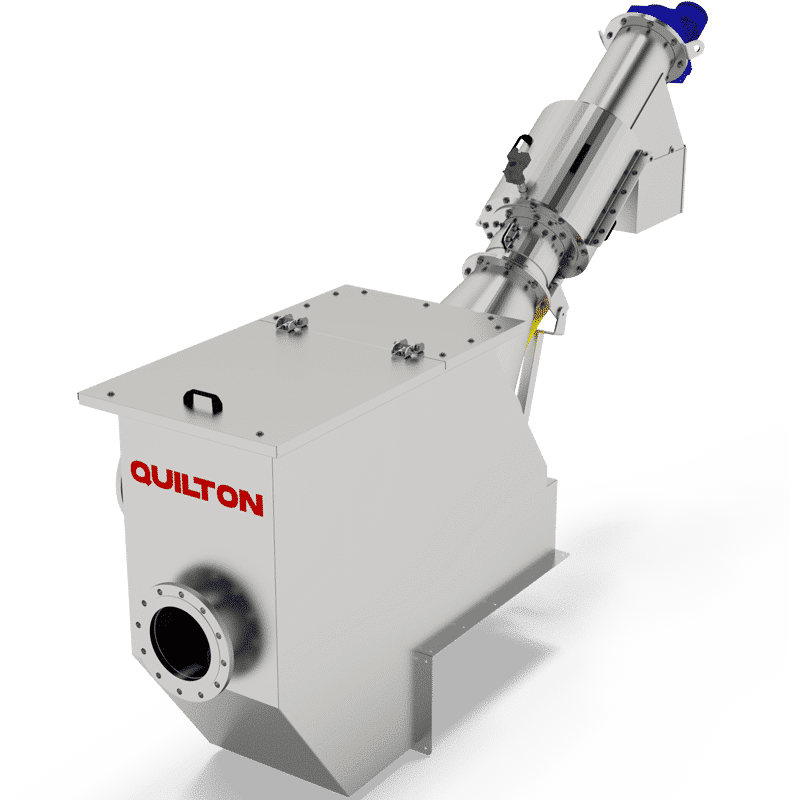

The design of the QUILTON self-cleaning band screen compact plant combines a tub with a QUILTON self-cleaning screen, which allows for the use of a self-cleaning screen without the need for a trough, using flanged connections.

Thanks to this design, QUILTON has provided an effective and safe solution for customers with problems of space and without the option of installing a trough. This means avoiding the costs and all the drawbacks involved in a civil engineering project.

This is a multipurpose piece of equipment with a very broad and varied sphere of application: from operations at wastewater treatment plants (WWTPs) for screening in the pre-treatment or treatment of sludges, to the removal of solids floating in the effluents from different types of industries.

Features and structure

The QUILTON self-cleaning band screen compact plant is distinguished by its large screening capacity, its exclusive self-cleaning system, and its high performance in continuous and intermittent operation. Its adaptability to existing and new facilities, the efficient self-cleaning of the screen, and the minimal maintenance required make this screen the solution for numerous problems at facilities and the ideal one because of its uses.

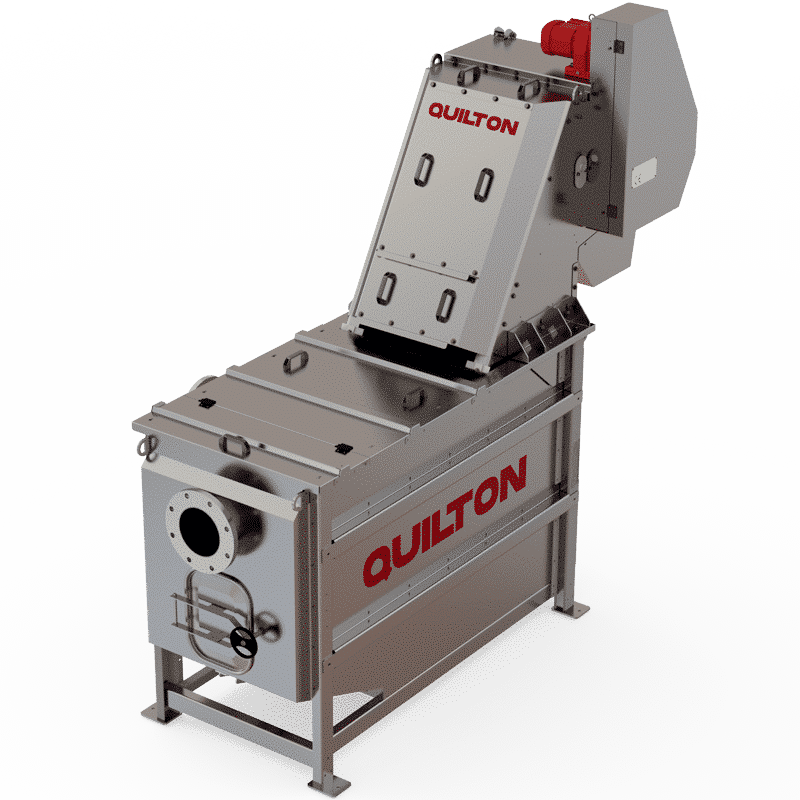

The QUILTON screen is placed directly inside the tub and the solids in suspension in the water are decanted, removed, and offloaded over the lip. In addition, it has optional auxiliary systems for washing the solids removed.

STRUCTURE

The QUILTON screen consists of filtering components made of ABS, referred to as "teeth", which are mounted on two consecutive stainless-steel shafts. The ends of these shafts hold the drive belts for the filtering screen. The unit, with its drive motor and other features is mounted on a stainless-steel structure.

The design of the teeth and their assembly on the filtering screen provide two filtering stages, determine the size of the solid to be extracted, and define the screen’s spacing.

SELF-CLEANING CAPACITY

QUILTON screens are self-cleaning simply through the effect of the screen’s movement. This means the teeth make a double movement due to the arrangement of each tooth’s assembly and the positioning of each row of teeth on two consecutive shafts and the screen’s rotation:

- Forward: for offloading the solids extracted.

- Backward: for cleaning the teeth individually and the screen as a whole.

This self-cleaning system means the screen is always clean in the flow of liquid, which ensures that the QUILTON screen operates efficiently over the long term without supervision, with minimal maintenance.

Operation

Options in assembly and maintenance

ADVANTAGES OF THE SELF-CLEANING BAND SCREEN COMPACT PLANT

- No building works.

- Bespoke designs.

- Possibility of deploying mobile units.

- Turnkey deliveries.

- Flexibility catering for different treatments, flows and solid concentrations.

APPLICATIONS OF THE SELF-CLEANING BAND SCREEN COMPACT PLANT

- Extension of existing pre-treatment processes.

- Treatment of sludges with high capture ratios.

- Multiple uses in industry.

OTHER EQUIPMENT

Related equipment