This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

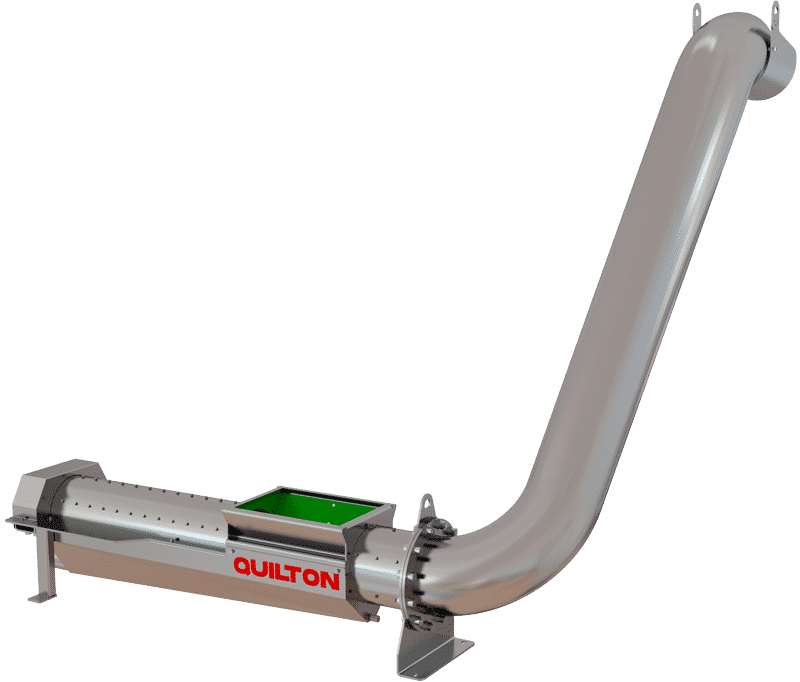

Screenings wash press

Compaction

The QUILTON screenings wash press is used for transporting, compacting, and dehydrating wastes and other damp or wet materials from the roughing or screening of urban or industrial wastewaters. These wastes are normally moved or elevated over short distances of around 1-2 metres.

A QUILTON screenings wash press basically consists of a main body made of stainless steel with a support structure, a conveyor or transport area, and a compacting and discharge area.

Features and structure

The main structure of a QUILTON screenings wash press is a frame that contains all the components required for the compacting process. This structure is mounted on a flat base and held in place by means of supports and attachment bolts.

It may be built using different types of stainless steels in a range of sizes and discharge rates, depending on each application.

The lower part is fitted with a drainage system with cone-shaped apertures to reduce clogging.

Both the cone shape (inverted funnel) of the apertures and the brush on the spiral reduce clogging and ensure the drainage area remains clean and free for the discharge of water and other drained liquids.

CONVEYOR SYSTEM

There is a spiral with a shaft under the inlet hopper that moves the product to the compacting area. This step involves both product transport and washing (thanks to an inner piping arrangement), as well as drainage. In this drainage area, the outside of the spiral is fitted with a brush.

The conveyor system consists of a spiral connected by a flange to a gear motor that turns the horizontal shaft.

The waste press leads into a compacting area, where the final section of the spiral is reinforced with a double thickness to ensure the waste is driven forward, avoiding any damage to the equipment.

DISCHARGE SYSTEM

The compacting area consists of a section without a spiral through which the product moves slowly. The tubular body, with antiwear guides on the inner part, has a flange connection with the outlet for the discharge pipe.

The discharge arrangement on QUILTON screening wash press basically involves flanged piping and a discharge head for compacting the solids and offloading them into a skip.

Operation

Generally speaking, a QUILTON screening wash press is fed from an inlet hopper. The material is washed and pressed to reduce its volume and organic matter content and increase its dryness.

The washed and partially dehydrated and compacted material is pushed toward an outlet pipe where the option is available of installing a counter-pressure device.

The water forthcoming from the pressing is returned to the trough via a collector tray that usually ends in a flange.

The load capacity of the screenings wash press varies according to the piston`s diameter and the number of cycles it performs. The waste input volume is reduced by between 40% and 60% after compacting.

The surplus water in the solids is removed via the compactor’s drainage system.

Options in assembly and maintenance

ADVANTAGES OF THE SCREENINGS WASH PRESS

- Compact and aseptic.

- Adaptable inlet and discharge position.

- Possibility of adjusting the degree of dryness.

- Models adapted to inlet flows.

- High dryness rates.

OTHER EQUIPMENT

Related equipment