This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

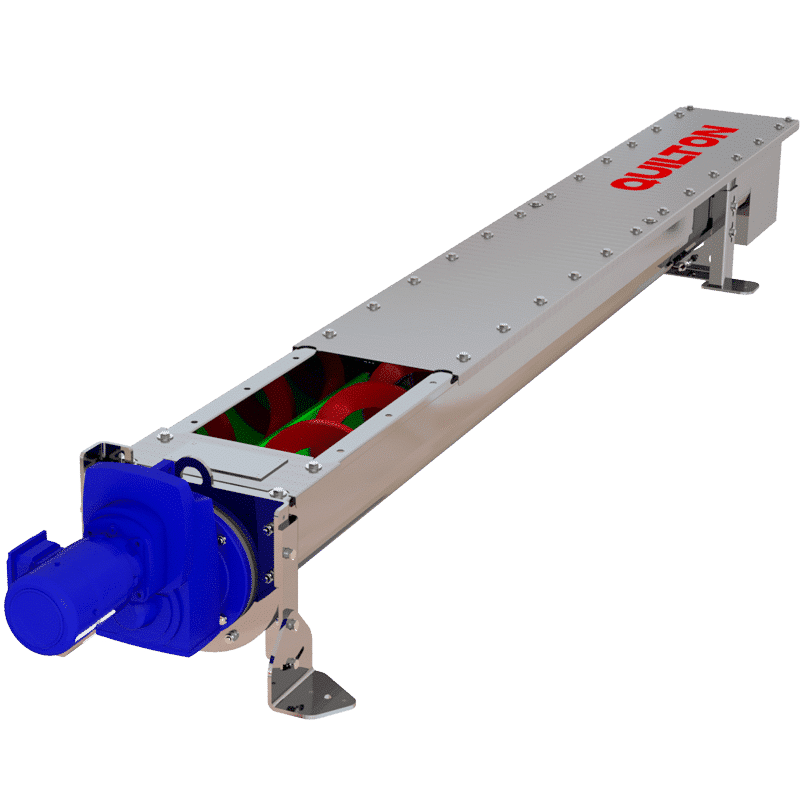

Compacting conveyor

CONVEYORS

The QUILTON compacting conveyor takes a single step to transport, compact, dry and discharge the solids retained and decanted by screening in WWTPs and industrial processes.

The adjustment of the length of the spiral and the pressure exerted by the outlet flapper are used to regulate the compacting process in the pressing area, which means variations in the feed do not influence the process’s results. The volume of solids is reduced to between 35% and 40% of the initial content.

Features and structure

The feature that differentiates a QUILTON compacting conveyor from a standard screw conveyor is the compacting head, which basically consists of the following components:

- Reinforced triangular-shaped drum with a 1 mm fine screen made of AISI-316L stainless steel.

- Cleaning system.

- Pressure-regulated flapper.

- Drainage pan.

As the spiral has no central shaft, it is always in contact with the trough, which is protected by a replaceable sleeve. There are different kinds of protective sleeves, which are made of ultrahigh molecular weight polyethylene (PE-1000 UHMW), Adiprene…depending on the material to be moved. In order to reduce wear, the conveyor auger should be filled with as much material as possible when in operation.

The compacting conveyor is fitted with drainage sections for decanting the liquids in the solid materials.

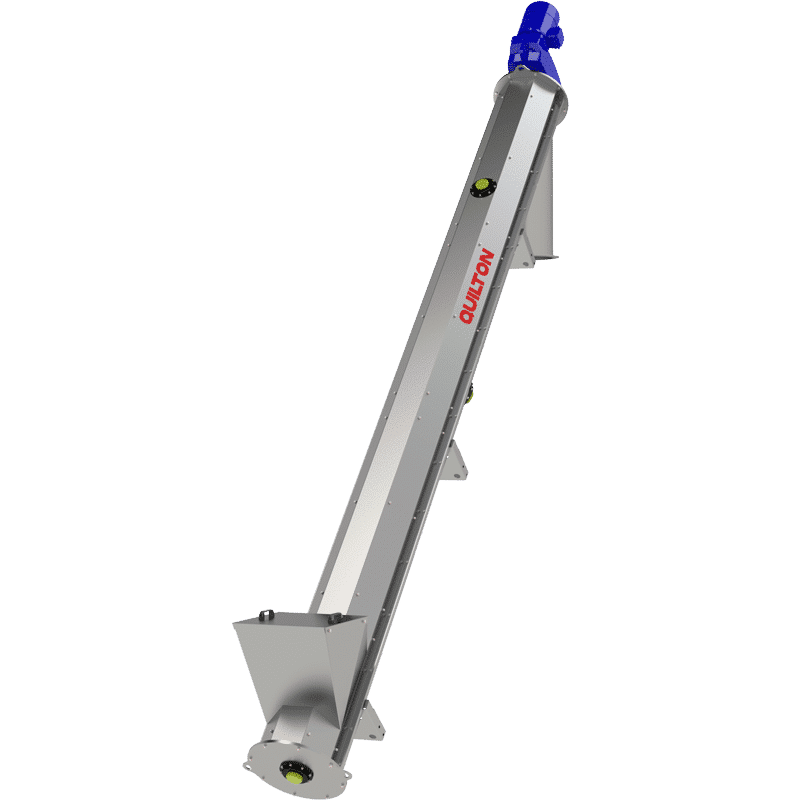

The spiral is modified or supplemented in some installations for the following reasons:

- Increase the capacity of sloping screw conveyors.

- Increase the strength of the screw on very long screw conveyors and on compacting conveyors.

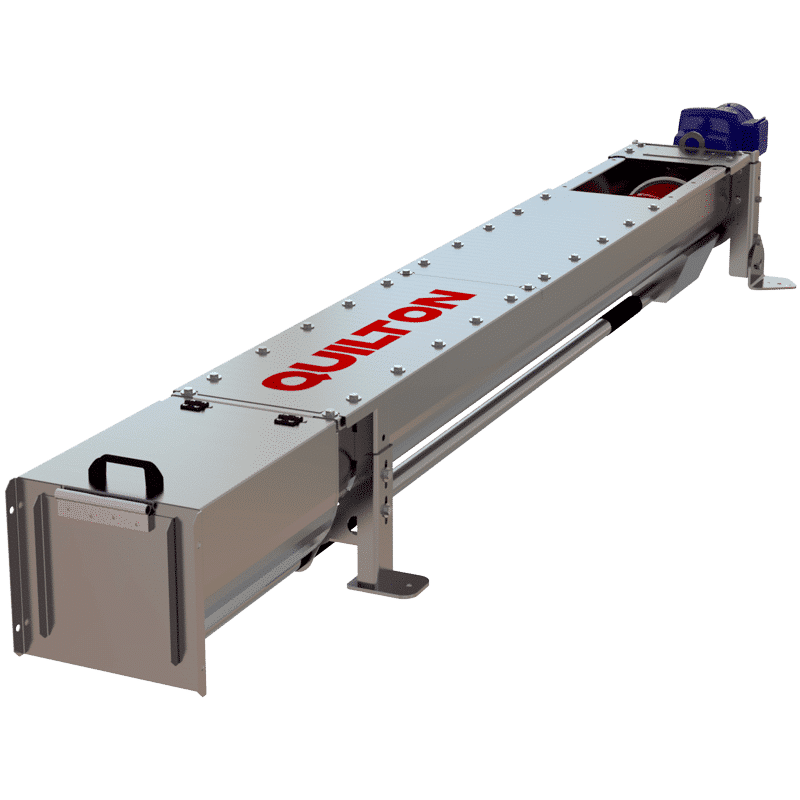

THE QUILTON COMPACTING CONVEYOR IS SUPPLIED WITH THE FOLLOWING:

- A sealing system on the drive shaft.

- Drainage area with a brush.

- Cleaning ramp in the pressing area.

- Connecting pipe for the single-point discharge of drainage and pressing waters.

- Robust V-shaped filtering drum in the compacting area.

Operation

Options in assembly and maintenance

ADVANTAGES OF THE COMPACTING CONVEYOR

- One-stop transport and compacting.

- No risk of clogging and guarantee of safe working conditions because of the design and structure of both the equipment and the spiral.

- Runs of up to 10 m with standard equipment.

- Major ability to adapt to all kinds of installations.

- Possibility of discharges from other equipment.

- Simple and robust design.

- Minimal operating and maintenance costs.

- High capacity in transport, compacting and removal of solids.

- Customised design and manufacture for customers.

APPLICATIONS OF COMPACTING CONVEYORS

- Water treatment:

- Transport of large and small solids from roughing.

- Transport of dried sludges.

- Agricultural and agrofood industries.

- Food production and packaging industries.

- Chemical plants and paper and pulp factories.

- Incineration plants: solid fuels.

- Mining industry.

OTHER EQUIPMENT

Related equipment