This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

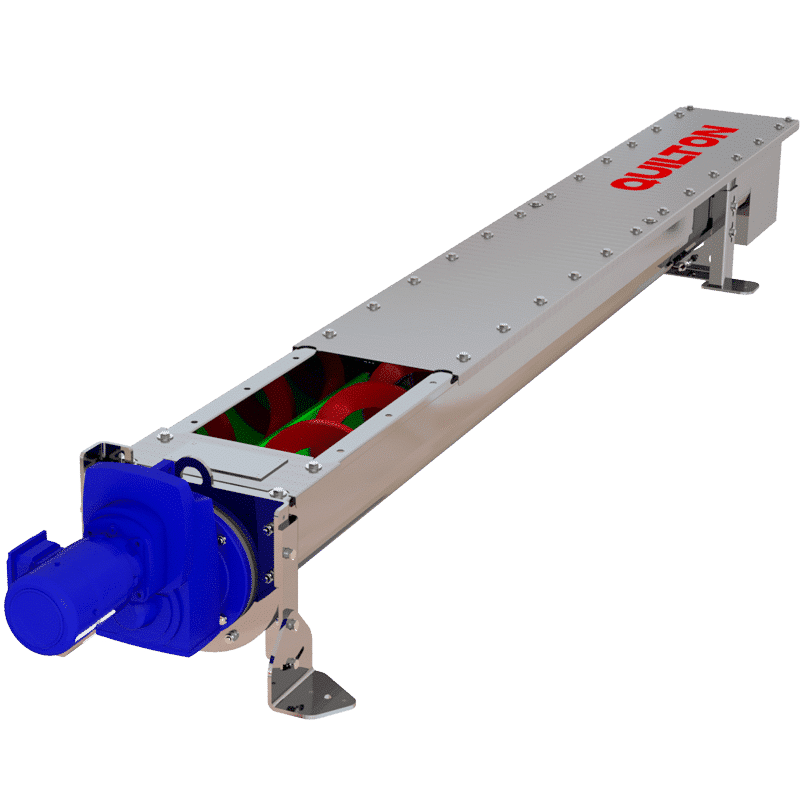

Grit washer

Washer

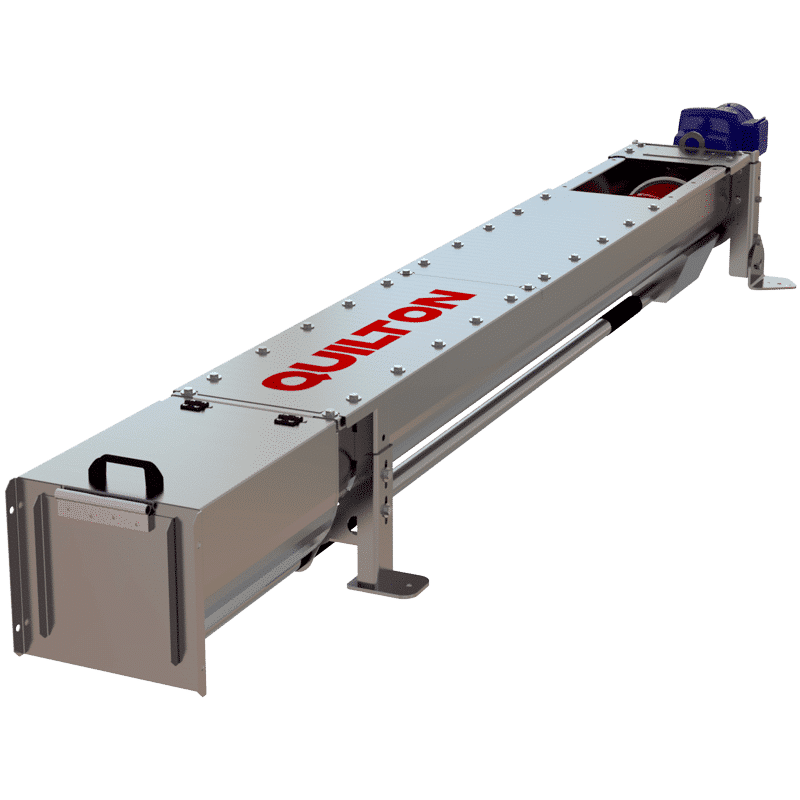

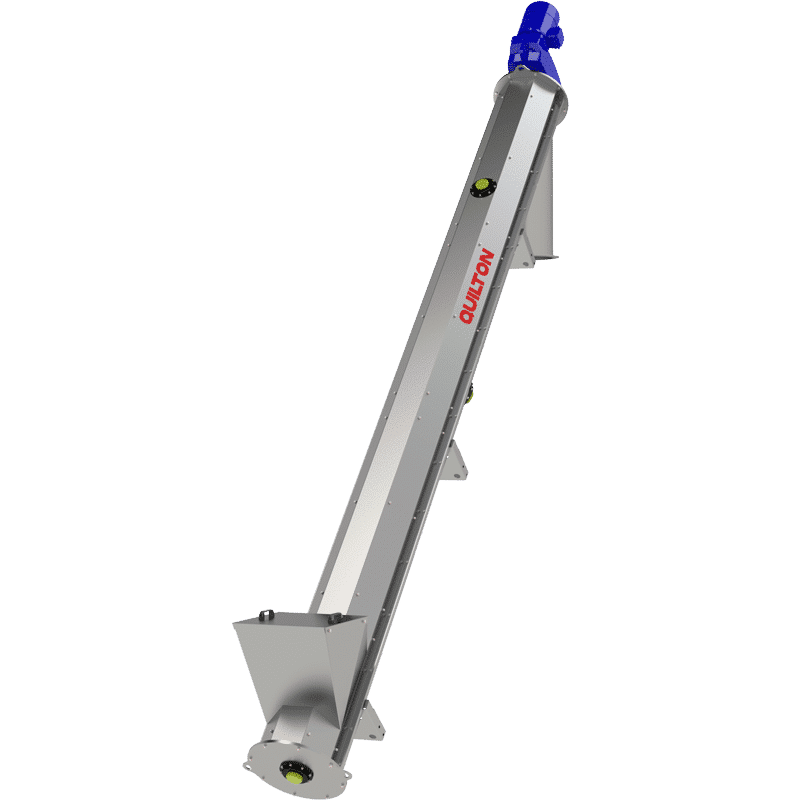

The design of the QUILTON grit washer involves two core components: the grit washing tank and the discharge screw. The process of classifying and washing grit requires a small amount of water and low inlet pressures. The grit washer provides a high performance with low maintenance costs, delivering top quality grit with a reduced organic material content.

The QUILTON grit classifier and washer has been designed mainly for the following purposes:

- High performance in the decanting of very fine particles of grit.

- Washing grit to improve its offload quality.

Features and structure

The QUILTON grit washer may be upgraded to become a receiving station for sand from septic tanks. This involves mounting an input roughing station for the removal of solids and the subsequent washing and classifying of grit.

The option is available of mounting the grit washer on the desander’s gantry and feeding it with the cleaning water provided by the desander itself.

The equipment’s design and structural specifications make it suitable for outdoor operations, tolerating conditions of high humidity and low temperatures.

Operation

The mixture of grit and water is fed into the sand washer and classifier through the inlet flange on the washing tank. The grit precipitates in the tank more quickly, while the organic material remains in suspension longer. When the cleaning water is added, the sediment is separated from the remaining organic materials during the washing process. This washing process is enhanced by the use of a shaking device and upward currents. Finally, the grit is removed from the tank, dried, and offloaded via an screw.

Options in assembly and maintenance

ADVANTAGES OF THE GRIT CLASSIFIER-WASHER

- Robustly built. Material qualities: stainless steel (AISI 304, AISI 316, etc.).

- Highly reliable.

- Option of upgrading to a receiving station for sand from septic tanks.

- Range of sizes depending on flow rate.

- Excellent cost-performance ratio.

- Reduction of organic content to less than 3-5% of volatile solids.

- Adaptability to changing operating conditions.

- Standalone equipment.

- Very low maintenance costs.

- Proven efficacy both at home and abroad.

APPLICATIONS OF THE GRIT CLASSIFIER-WASHER

Solution for municipal plants:

- Pre-treatment of wastewaters and treatment of grit.

- Receiving station for grit from septic tanks.

- Compact installations.

Industrial uses:

- Meat, fish and shellfish processing.

- Abattoirs.

- Sugar industry.

- Fruit and vegetable processing.

- Breweries.

- Composting facilities.

- Machinery industry.

- Glass and ceramics transportation.

OTHER EQUIPMENT

Related equipment