This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

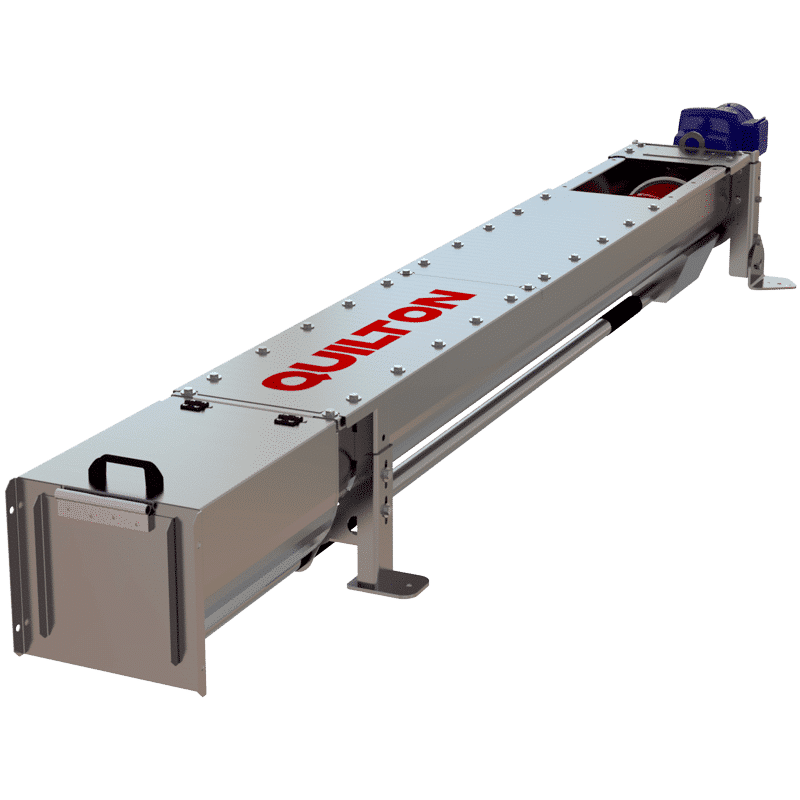

Screw conveyors

CONVEYORS

Screw conveyors are used mainly for moving solids in WWTPs. This equipment ensures that all the solids produced by roughing and desanding are easily moved and discharged.

The structure and design of QUILTON screw conveyors involves a spiral without a central shaft that is extremely robust and made of thick steel. The spiral section is reinforced in some applications for greater strength and transport capacity. It is also equipped with a low-rev gear motor.

QUILTON shaftless screw conveyors replace standard conveyor belts because of their safety and cleanliness.

Features and structure

The material to be moved is fed and discharged by one or more inlets/outlets that may be supplemented by knife gates and valves.

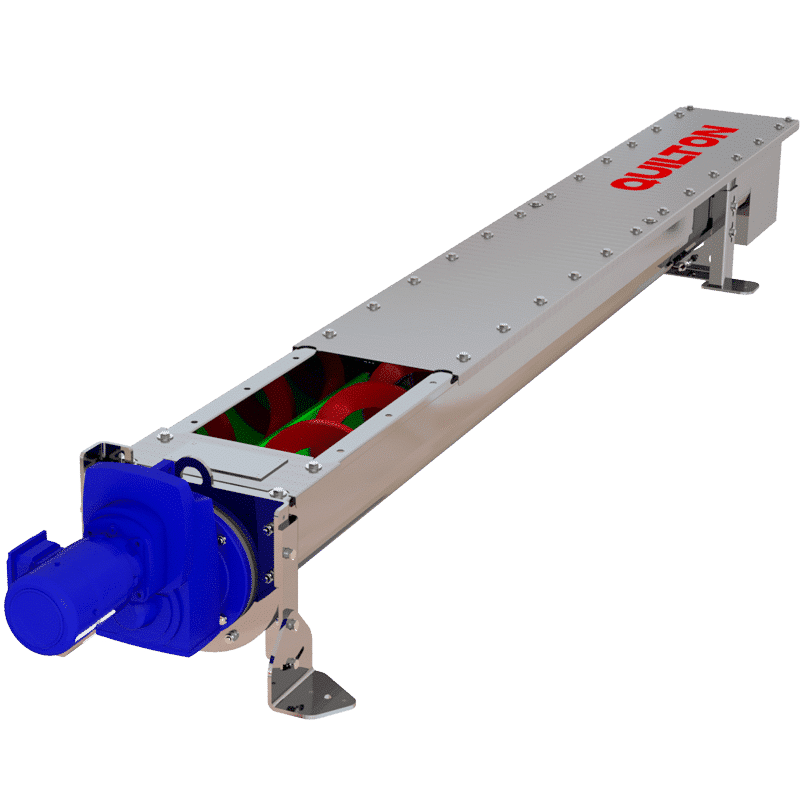

The material is moved by a robust steel spiral. It is a helicoid without a central shaft or core, with greater conveyor capacity, less sensitivity to fibrous or clogging materials, and the ability to transport products in a wide range of sizes.

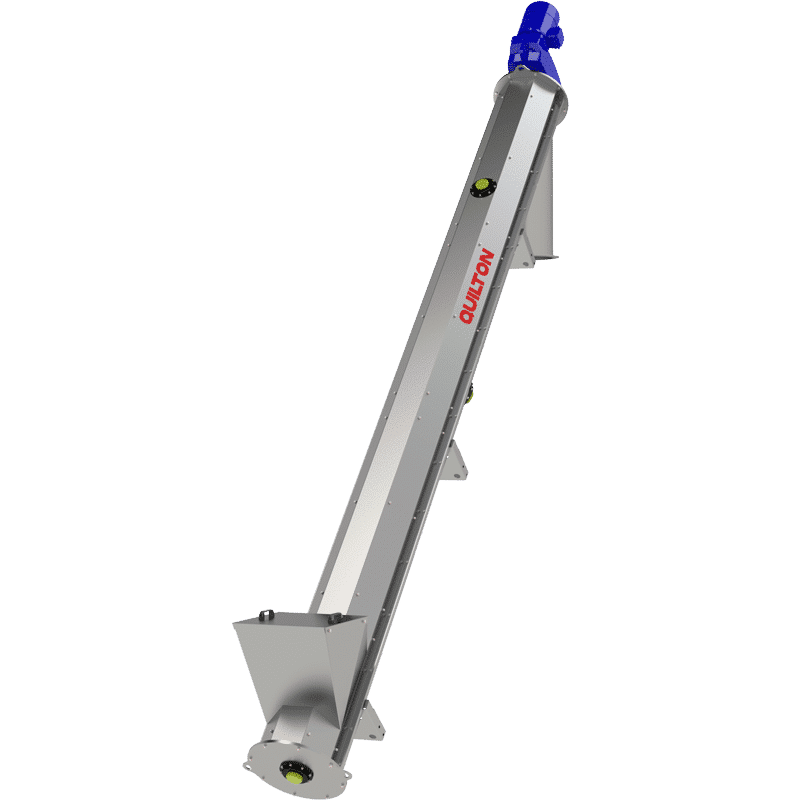

Screw conveyors cater for highly compact installations in a reduced space. Screw conveyors operate by “pushing” or “pulling”. A screw conveyor that operates by “pushing” can directly feed a second screw conveyor by coupling one to the other, without requiring the use of hoppers. The second screw conveyor may be mounted at a different angle and/or direction to the first one.

As the spiral has no central shaft, it is always in contact with the trough, which is protected by a replaceable sleeve. There are different kinds of protective sleeves, which are made of ultrahigh molecular weight polyethylene (PE-1000 UHMW), Adiprene…depending on the material to be moved. In order to reduce wear, the screw should be filled with as much material as possible when in operation.

The screw may be fitted with drainage sections to facilitate the decanting of the liquids in the solid materials. The effective dehydration of the solids being transported requires the use of the compacting conveyor.

The spiral is modified or supplemented in some installations for the following reasons:

- Increase the capacity of sloping screw conveyor.

- Increase the strength of the screw on very long screw conveyors and on compacting conveyors.

Operation

Options in assembly and maintenance

ADVANTAGES OF SCREW CONVEYORS

- Possibility of moving products in a very wide range of sizes.

- No danger of blocking, as there is nothing to hinder a product’s progress.

- Greater transport capacity.

- Greater sensitivity to fibrous materials or ones that lead to plugging.

- No danger of blocking, as there is nothing to hinder a product’s progress.

- Low energy consumption.

- Simple and robust design.

- Minimal operating and maintenance costs.

- Customised design and manufacture for customers.

APPLICATIONS OF SCREW CONVEYORS

- Water treatment:

- Transport of large and small solids from roughing.

- Transport of dried sludges.

- Agricultural and agrofood industries.

- Food production and packaging industries.

- Chemical plants and paper and pulp factories.

- Incineration plants: solid fuels.

- Mining industry.

- Desalination.

OTHER EQUIPMENT

Related equipment