This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

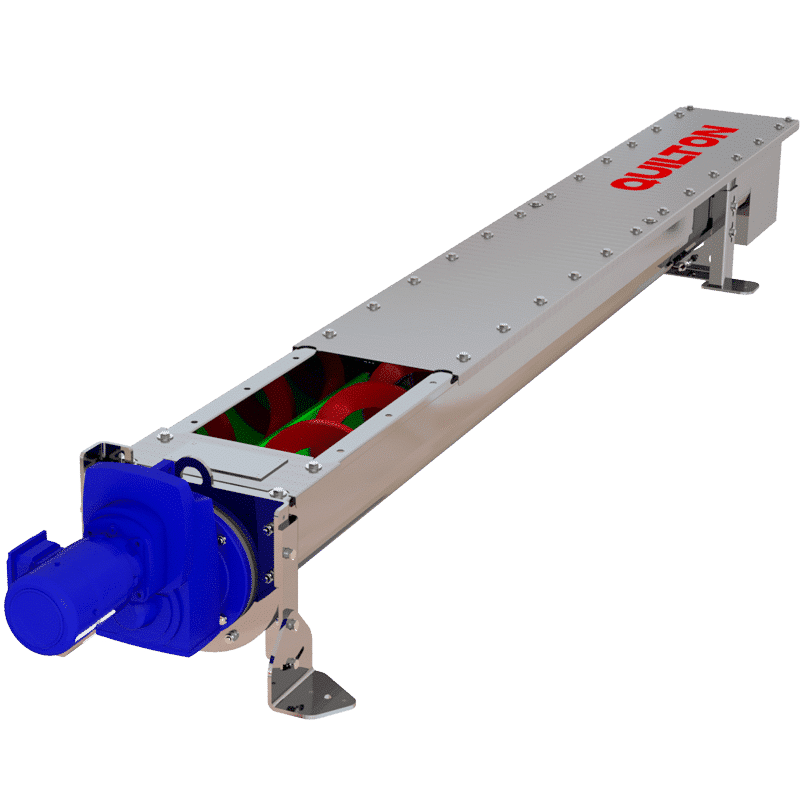

Screw elevators

ELEVATORS

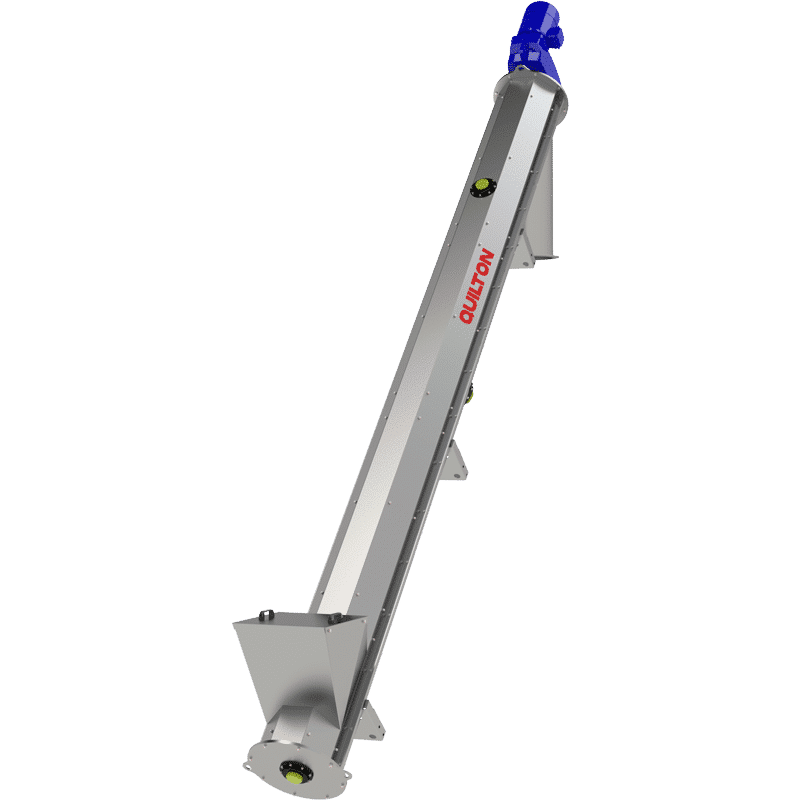

The QUILTON screw elevator is used to raise different kinds of solids at angles of more than 30º above the level. This is thanks to its orthogonal or cylindrical design (depending on the application). It is fitted with a robust shaftless spiral made of thick stainless steel and a low-rev gear motor.

This shaftless spiral arrangement provides the screw elevator with greater conveyor capacity, less sensitivity to fibrous or clogging materials, and the ability to transport products in a wide range of sizes. There is nothing to hinder the products’ progress, and the auger can be filled without any risk of blockage.

Features and structure

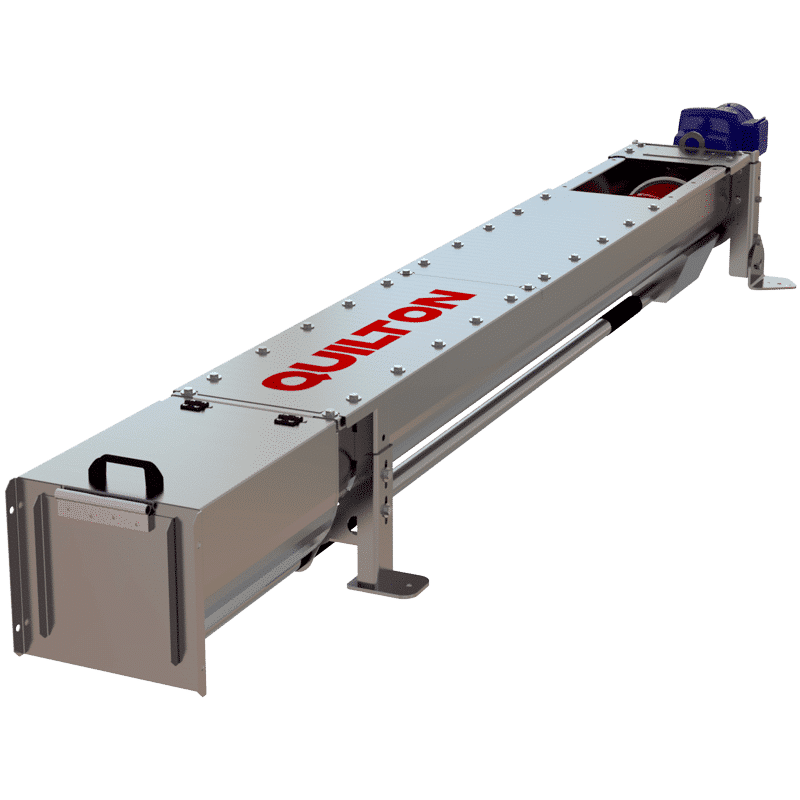

The screw elevator caters for highly compact installations in reduced spaces.

A screw elevator that operates by “pushing” can be coupled onto a second screw elevator and fed directly, without the need for an intermediate hopper.

The material is moved by a robust steel spiral. It is a helicoid without a central shaft or core, with greater conveyor capacity, less sensitivity to fibrous or clogging materials, and the ability to transport products in a wide range of sizes.

As the spiral has no central shaft, it is always in contact with the trough, which is protected by a replaceable sleeve. There are different kinds of protective sleeves, which are made of ultrahigh molecular weight polyethylene (PE-1000 UHMW), Adiprene…depending on the material to be moved. In order to reduce wear, the auger should be filled with as much material as possible when in operation.

Operation

Options in assembly and maintenance

ADVANTAGES OF THE SCREW ELEVATORS

- Greater transport capacity.

- Greater sensitivity to fibrous materials or ones that lead to plugging.

- Possibility of moving products in a very wide range of sizes.

- No danger of blocking, as there is nothing to hinder a product’s progress.

OTHER EQUIPMENT

Related equipment