This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

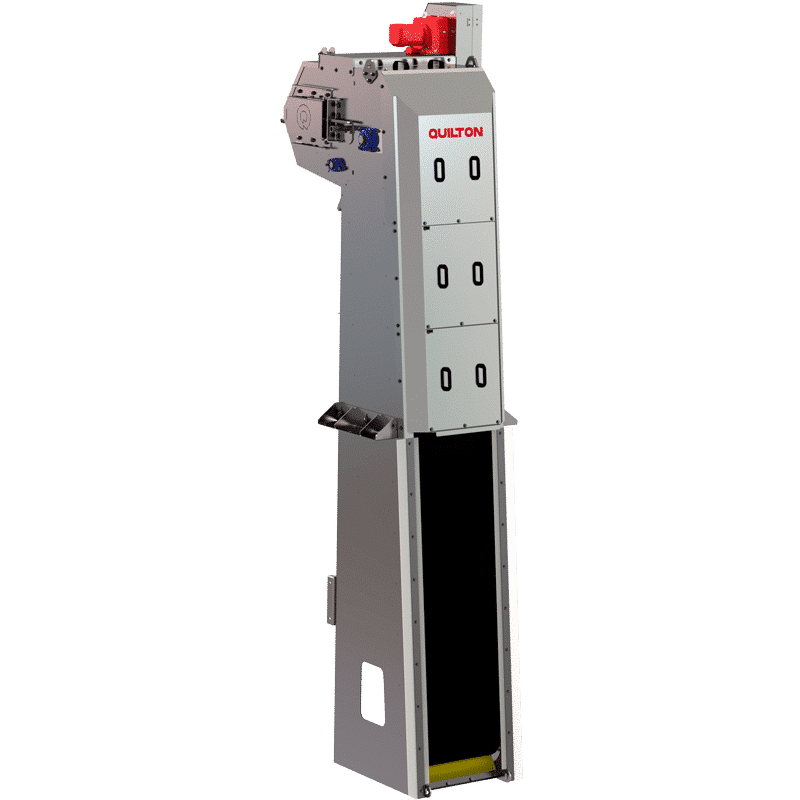

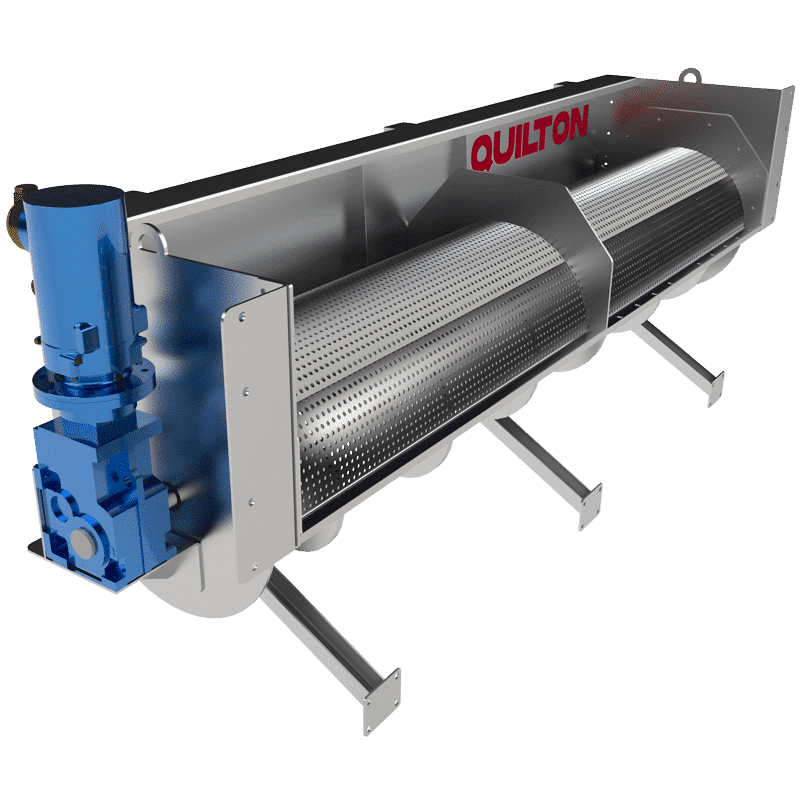

Automatic bar screen

BAR SCREENS

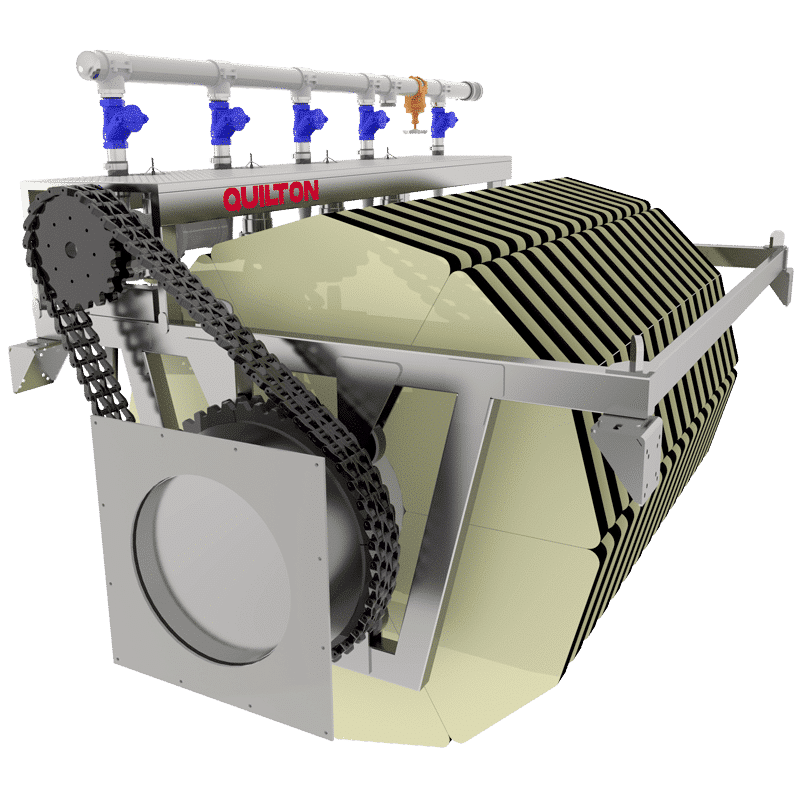

The QUILTON automatic bar screen for roughing removes medium and large-sized solids from the wastewaters that arrive heavily laden at the plants. The spacing determines whether the automatic bar screen is used for large items (12-25 mm) or very large ones (30-100 mm).

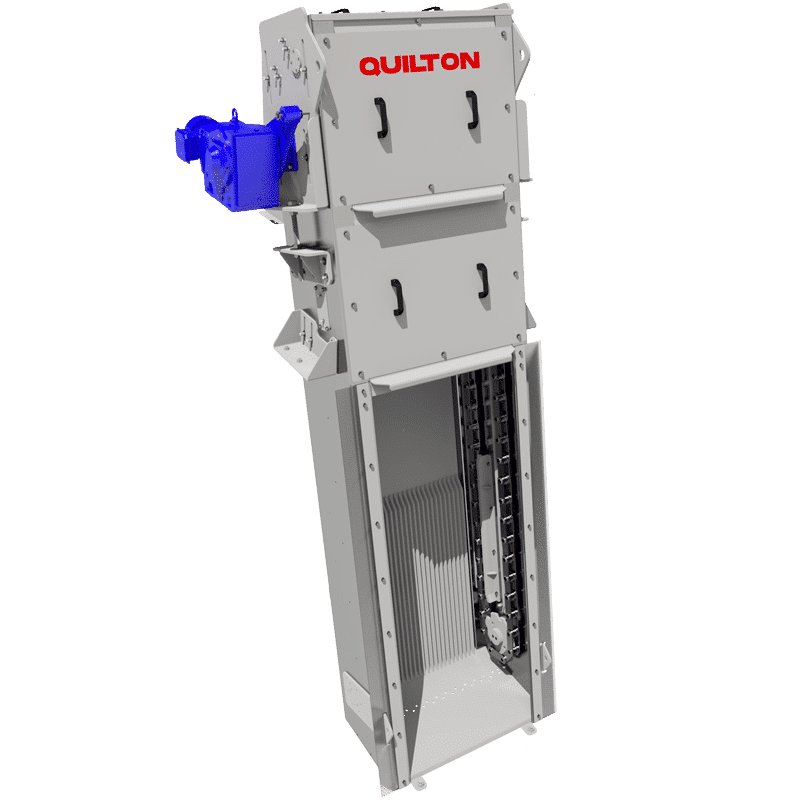

The solids retained are cleaned and removed by an autoptic comb.

The following are the QUILTON automatic bar screen´s structural components:

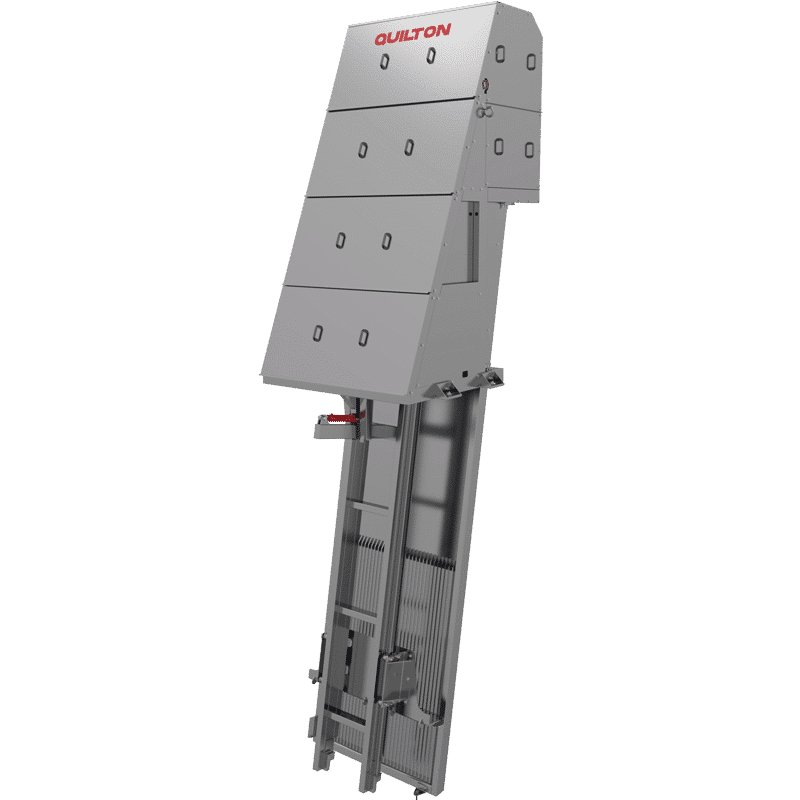

- Double metal frame, both are rigidly joined by attachment and fastening profiles. One of the frames holds the bar screen and the other frame, the carriage, holds the cleaning system and the rails required for the effective removal of the solids retained.

- Main drag chain for vertical displacement.

- Oleohydraulic unit and control panel and switchboard.

Features and structure

The QUILTON automatic bar screen is a roughing screen for large items that is used for the automatic removal of large floating and suspended items in a liquid flow. The size of the floating materials it can remove depends on the spacing on the bar screen.

The roughing bar screens at WWTPs are installed on the raw water inlet pipes. This model of bar screen caters for depths of up to 10 m. The raw water laden with solids may reach WWTPs directly via the drain and sewers or by pumping. In this case, the bar screens are installed upstream of the separation pumps and the screens for fine particles in order to protect them. The installation also includes automatic bar screens at the entrance to storm tanks to stop the passage of large or very large solids.

AUTOMATION AND PROTECTION OF THE AUTOMATIC BAR SCREEN

The device for cleaning the roughing bar screen, which generally operates on an intermittent basis, operation, can be automated through the following:

- Timer: the sequence is set depending on the estimated daily operating time.

- Pressure drop: the cleaning operation starts automatically when there is a pressure drop between the two sides of the mesh due to its partial clogging that exceeds a set figure.

- Combined system of timer and pressure drop.

The automatic roughing bar screen should be fitted with a torque limiter so that in the event of an overload or blockage, it will cut out to avoid any damage being caused.

STRUCTURAL, ELECTRIC AND HYDRAULIC FEATURES

- Simple, robust design.

- Quality of materials: stainless steel AISI 304, AISI 316, UNS-31803, UNS-32750…

- Eight-wheel carriage on the main frame.

- Manual and automatic operation.

- Option of automating other equipment on the control panel and switchboard.

- Direct control of all movements.

- Indicators for all parameters.

- Adjustable piston pressure.

- Double-action piston.

- Hydraulic unit with level and temperature sensors.

- Approved oil tank.

Operation

Options in assembly and maintenance

ADVANTAGES OF THE AUTOMATIC BAR SCREEN

- Adaptable to existing conduits.

- Low energy consumption.

- Maximum capacity for removing solids due to the oleohydraulic system.

- No lateral derailing of the carriage, as it is guided by eight wheels on the main frame.

- No moving parts underwater: only the carriage moves up and down.

- Easy assembly. No building work required, as it sits astride the channel.

- Safer and better performance than other options.

- No lubrication required, keeping maintenance and operating costs to a minimum.

- The carriage is easy to release if it becomes blocked thanks to the opening and closing of the cylinder, allowing for the removal of the solids blocking it.

USES OF THE AUTOMATIC BAR SCREEN

In urban wastewaters:

- Roughing of large and very large solids.

- Protection of the inlet to the WWTP and its pumps.

In captures involving channels (from rivers or seawater):

- Retention and removal of large solids.

- Retention and removal of large amounts of seaweed.

In industrial wastewaters:

- Removal of large solids before the next stages of the process.

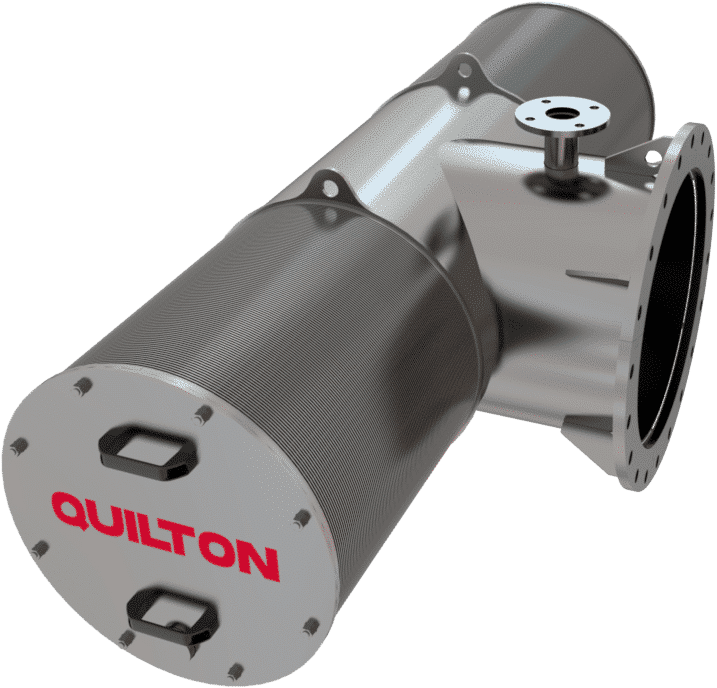

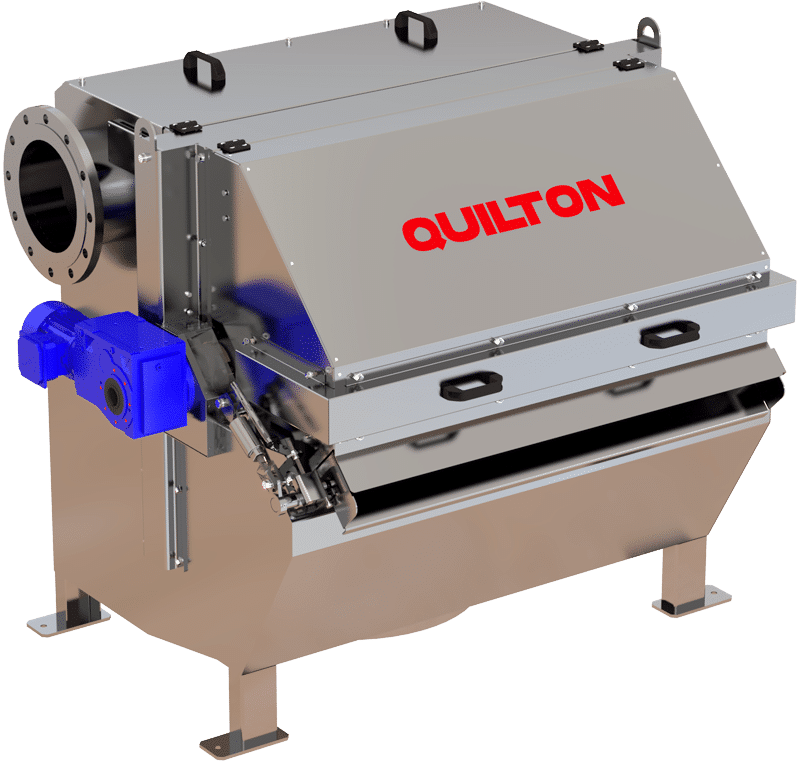

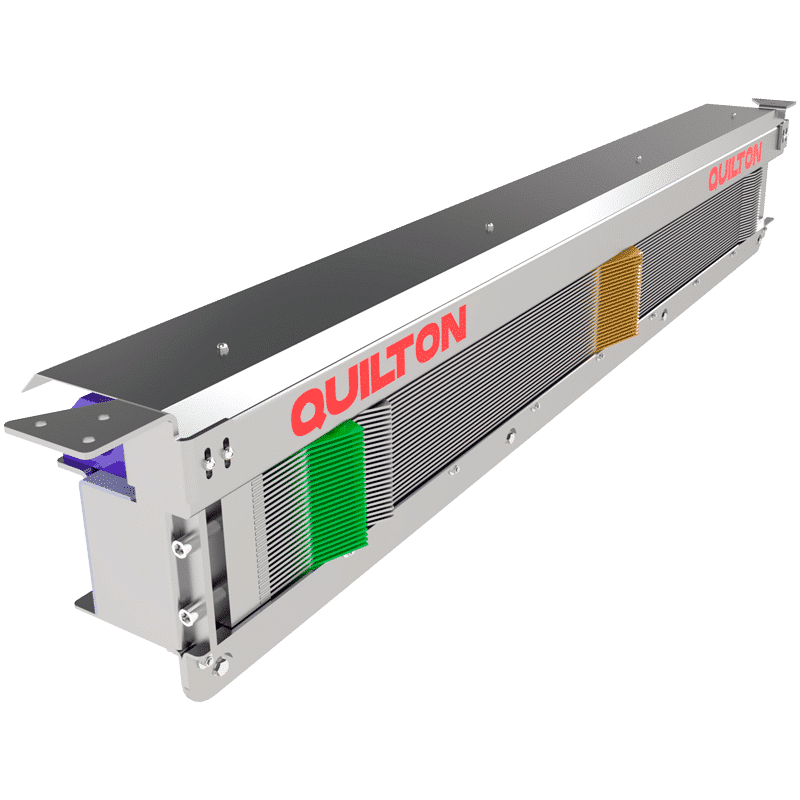

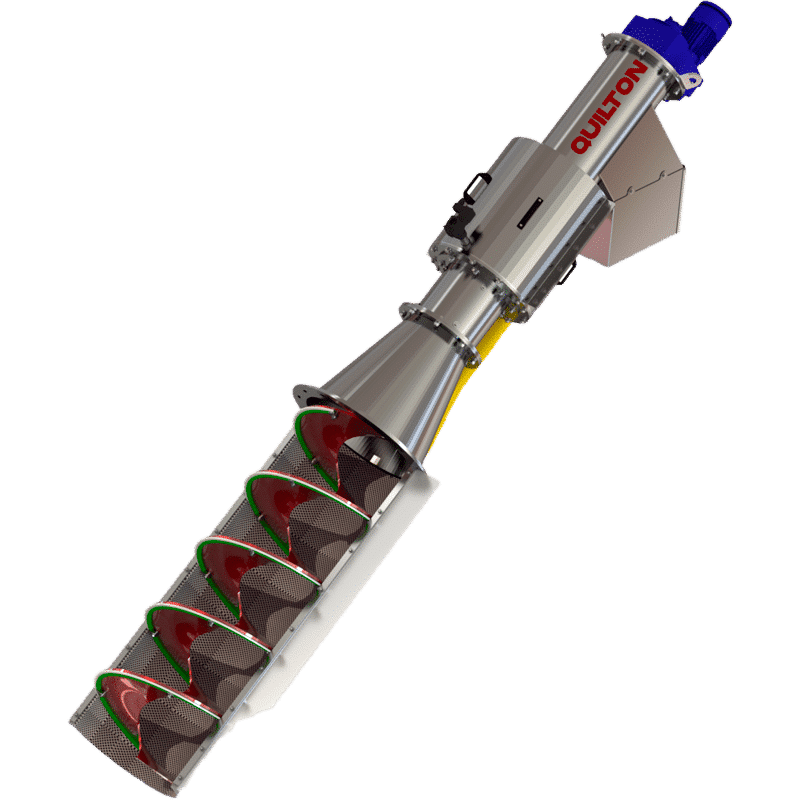

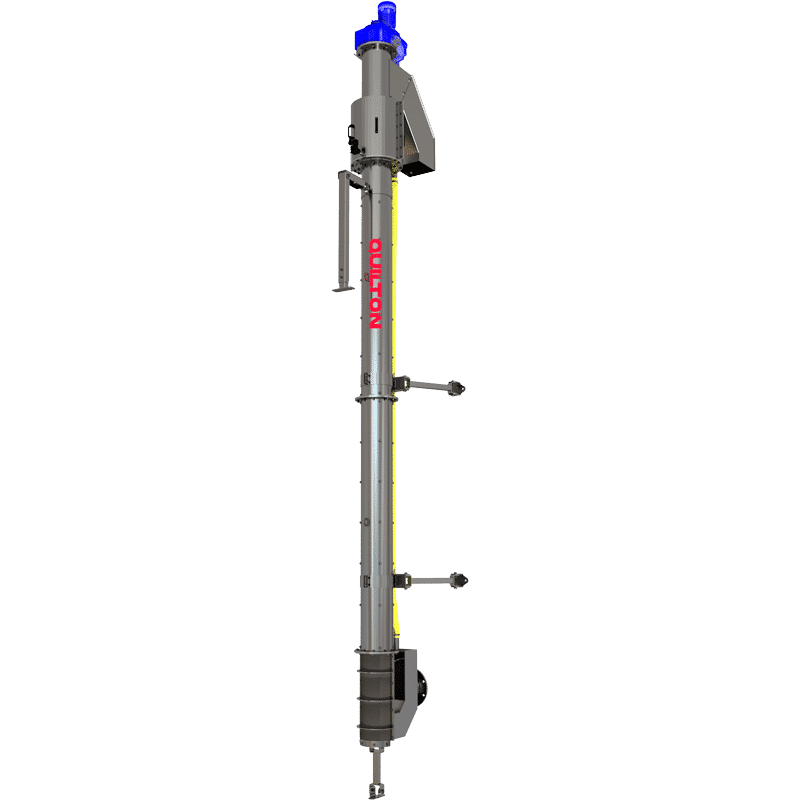

OTHER EQUIPMENT

Related equipment