This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

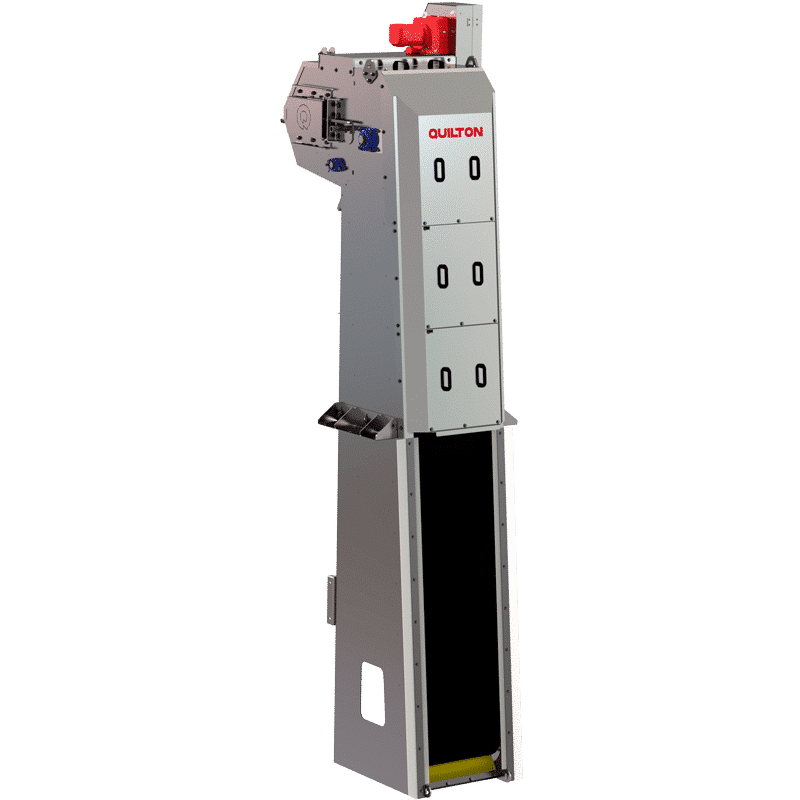

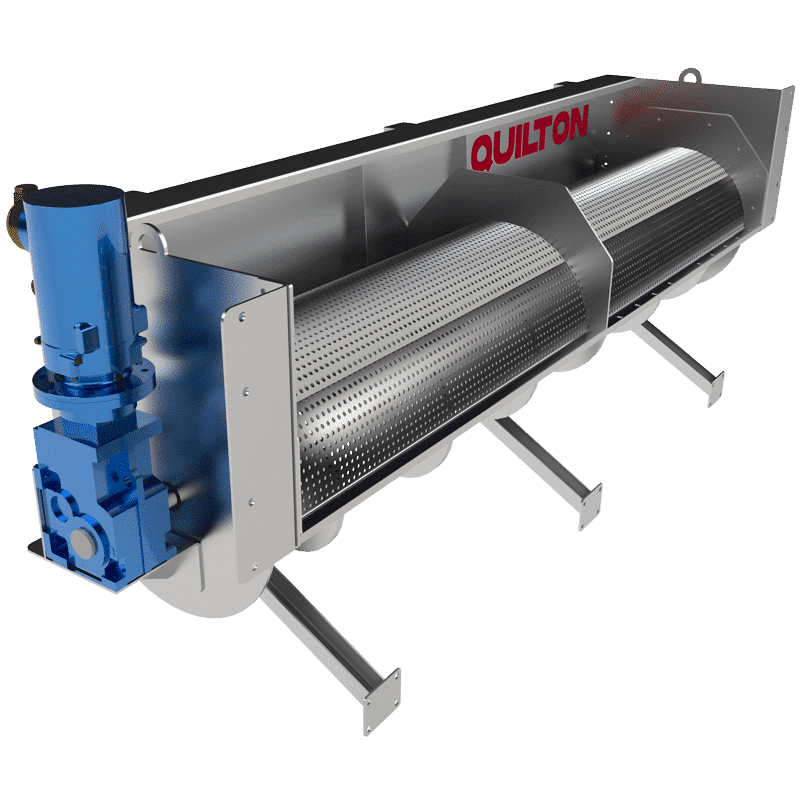

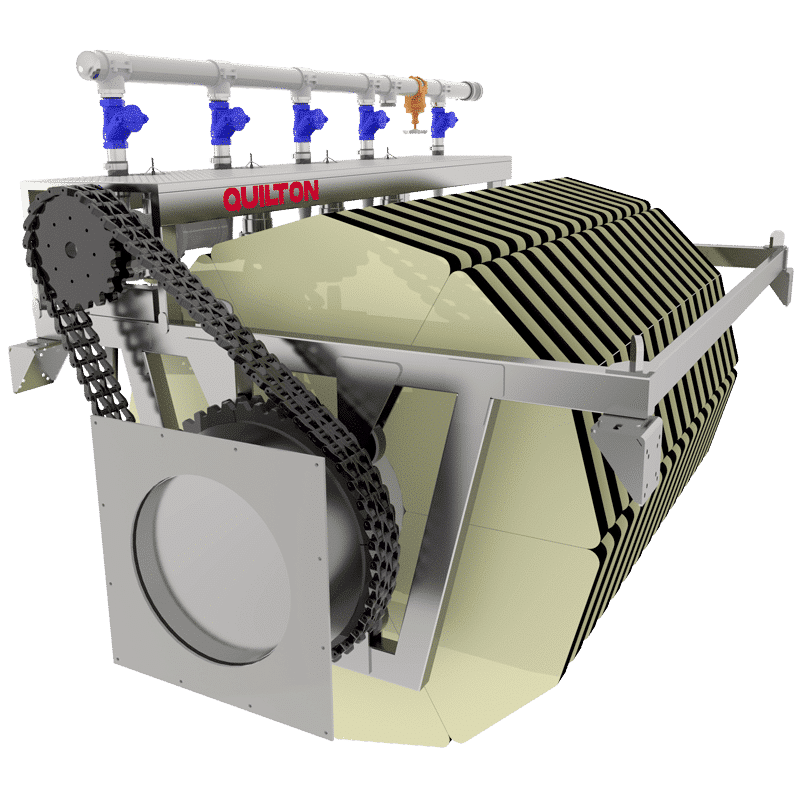

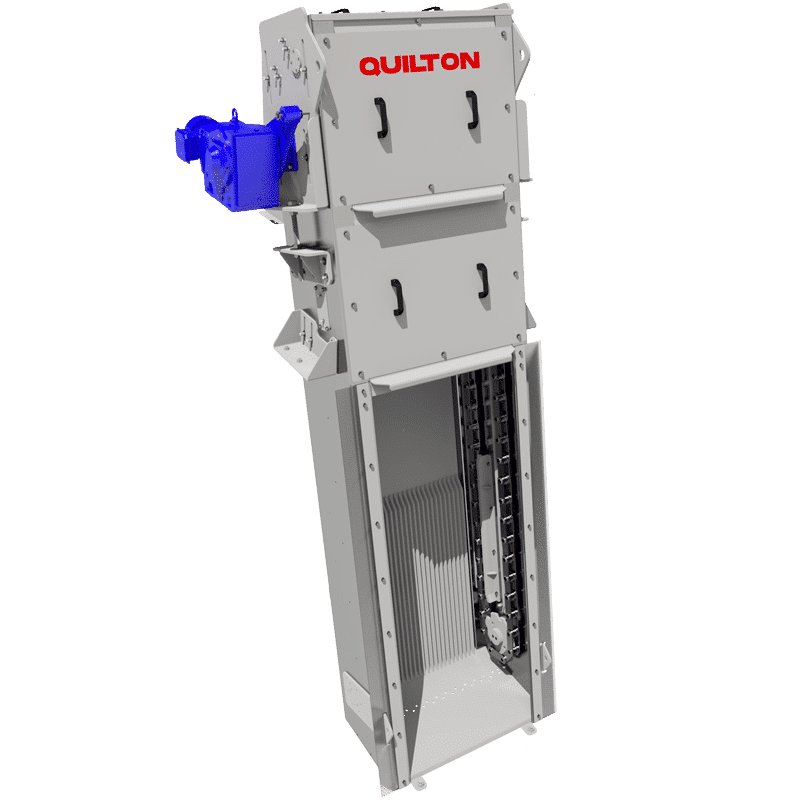

Multi rake bar screen

BAR SCREENS

The QUILTON automatic multi rake bar screen is an excellent high-performance product that operates continuously or intermittently. Its adaptability to new and existing channels, its minimal maintenance requirements and its low operating costs make it the ideal solution for numerous problems, adapting to each use’s different requirements and needs.

It consists of a stainless-steel chassis, robustly built with strong attachment and fastening profiles, which provide support and hold the bars that make up the mesh and whose separation defines the spacing required.

The wastewater flows though the bars on the multi rake bar screen, while those solids larger than the spacing are retained. The wastes are collected at the bottom of the channel and then transferred to the upper part, where they are discharged.

Features and structure

The QUILTON automatic multi rake bar screen has a series of structural features that make it one of the best options for roughing large solids.

COMPONENTS OF THE MULTI RAKE BAR SCREEN

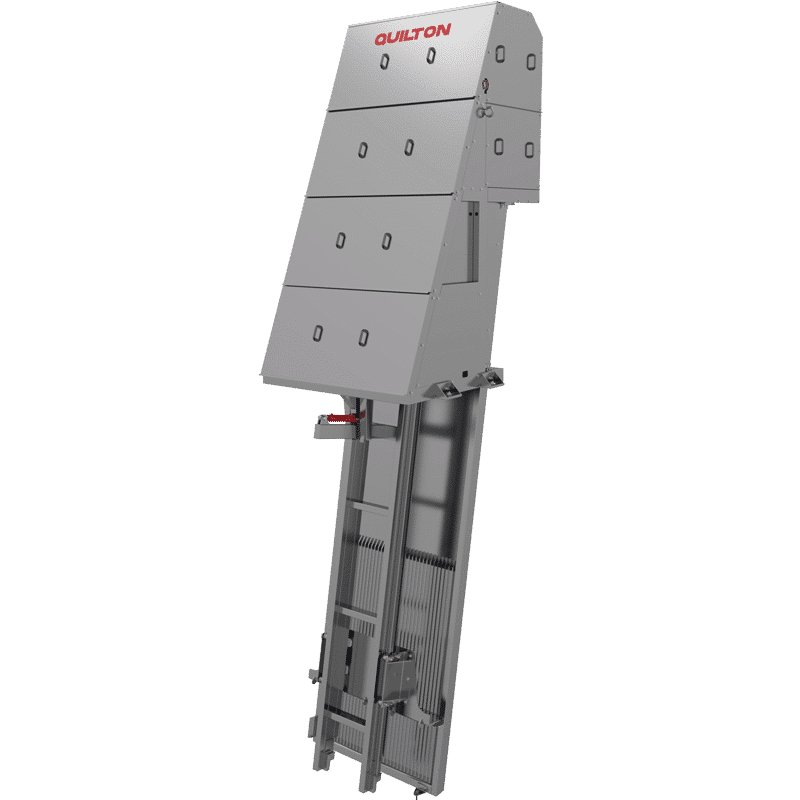

- Structure: a stable, solid structure involving two interconnected sides. This design arrangement means it can adapt to new and/or existing channels.The following material qualities are available: AISI-304, AISI-316, Duplex, Super Duplex, etc.

- Bars: these involve rectangular or trapezoidal profiles. The use and pressure drops involved will not only require a different spacing, but also different lengths of bars.

- Cleaning combs: the raking combs collect and raise the solids retained by the bars. The teeth are inserted between the bars on the bar screen without resting on them, and thereby suitably remove the roughed solids.

- Drive belts: the drive belts, mounted on the sides of the equipment, are used to convert radial movement into linear movement and convey that movement to the cleaning comb. For the manufacture of bar screens, QUILTON uses a preassembled belt that has undergone a special treatment to make it stronger and improve its resistance to corrosion. This treatment reduces wear and stretching, prolonging its useful life.

- Motor: the combs are displaced by a gear motor connected to the drive shaft, which in turn uses the lateral side rails to transfer its rotational movement to the guided movement of the chain. On all its bar screens, QUILTON installs gear motors made by leading brands to guarantee that its equipment provides a high performance at a low consumption.

- Cleaning system/scraper: this consists of a discharge ramp, and a soundly bolted PEHD 1000 polyethylene scraper. Its main purpose is to separate the roughed solids from the discharge ramp by gravity and deposit them in another piece of equipment or in a waste collection skip.

Operation

Options in assembly and maintenance

ADVANTAGES OF THE MULTI RAKE BAR SCREEN

- Optimum intermittent operation.

- High retention and removal of solids.

- Adaptability to existing channels.

- Bars in detachable and replaceable modules.

- Combs in detachable and replaceable sections.

- Reinforced guiderails to minimize maintenance costs.

- Streamlined design to avoid an excess of weldings.

- Straightforward installation. Attachment astride the channel using lateral supports.

- Low energy consumption.

USES OF THE MULTI RAKE BAR SCREEN

In urban wastewaters:

- Roughing of large and very large solids.

- Protection of the inlet to the WWTP and its pumps.

In captures involving channels (from rivers or seawater):

- Retention and removal of large solids.

- Retention and removal of large amounts of seaweed.

In industrial wastewaters:

- Removal of large solids before the next stages of the process.

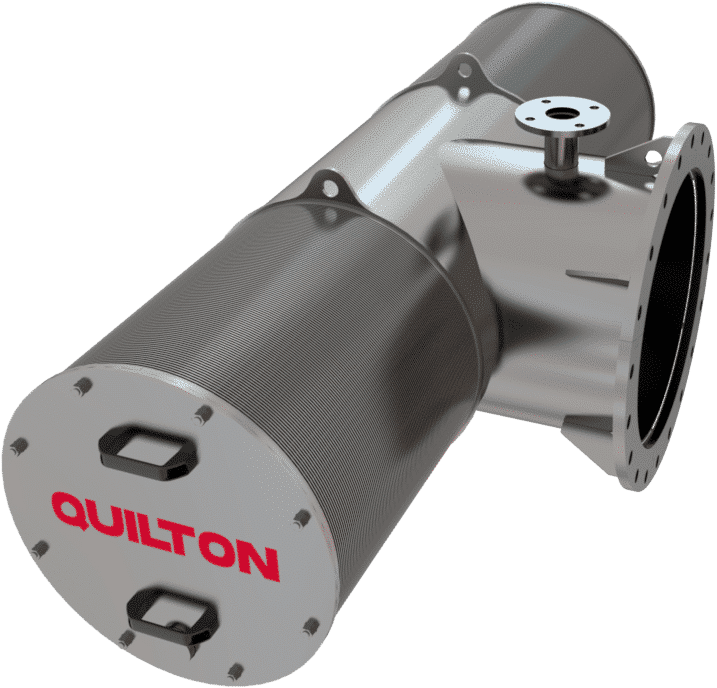

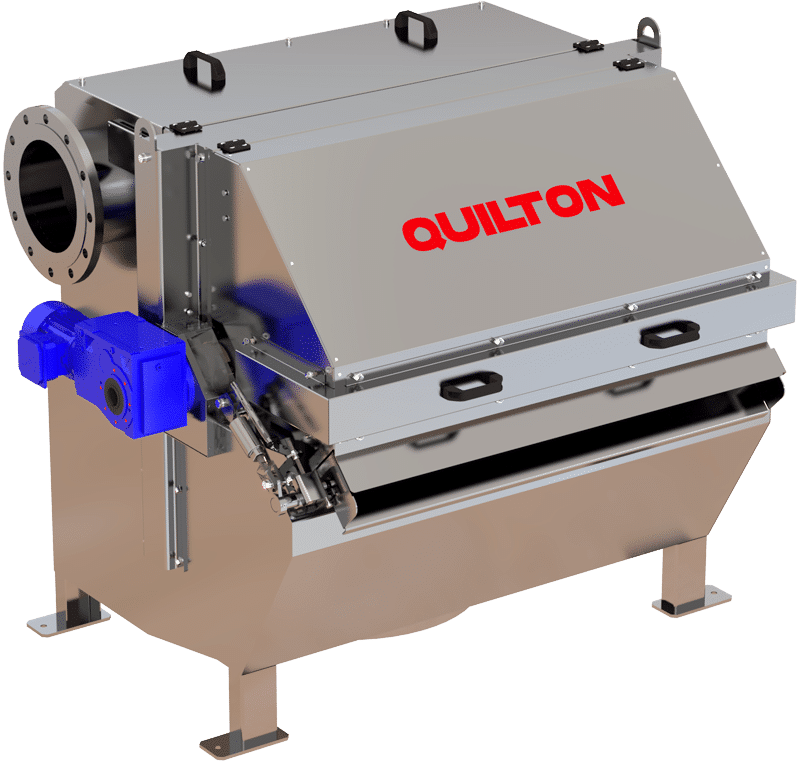

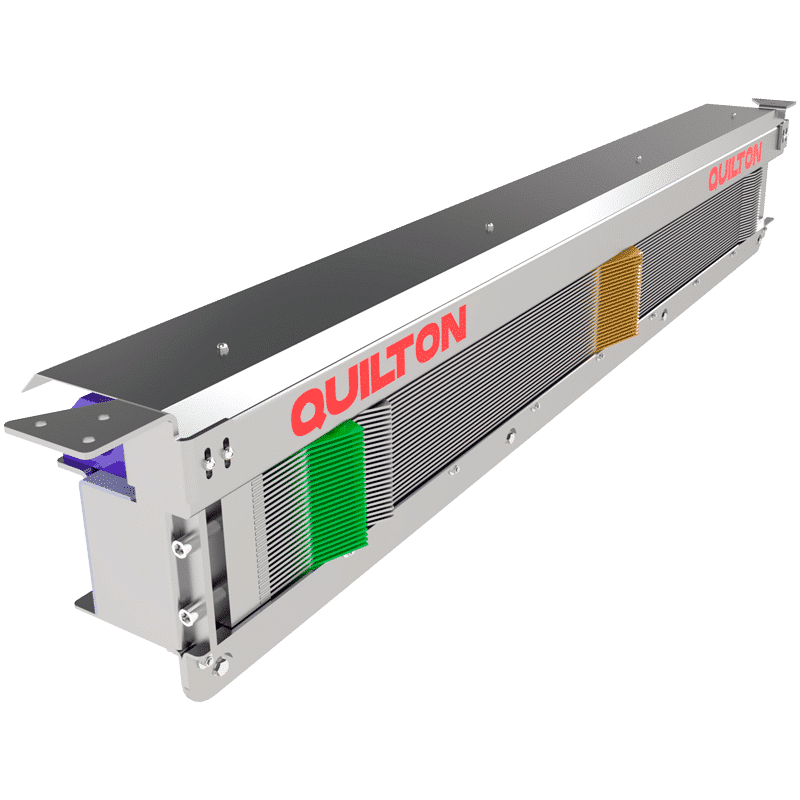

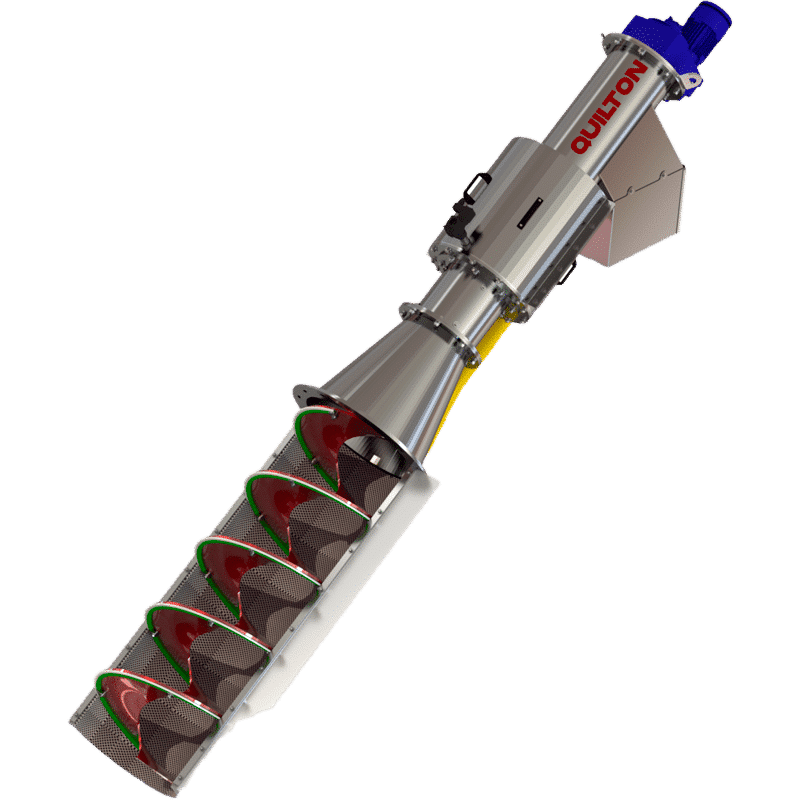

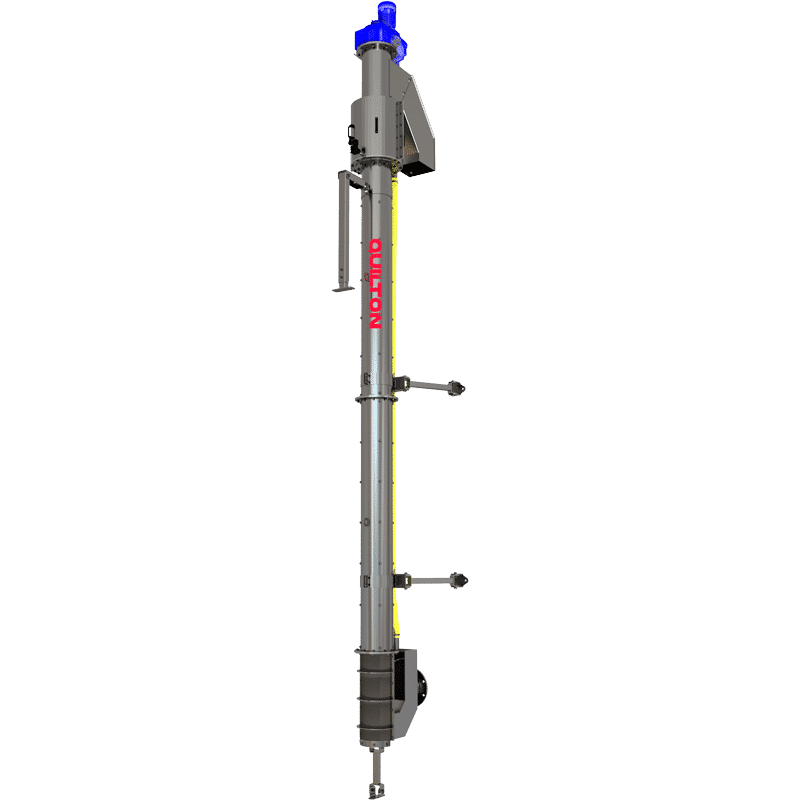

OTHER EQUIPMENT

Related equipment