This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

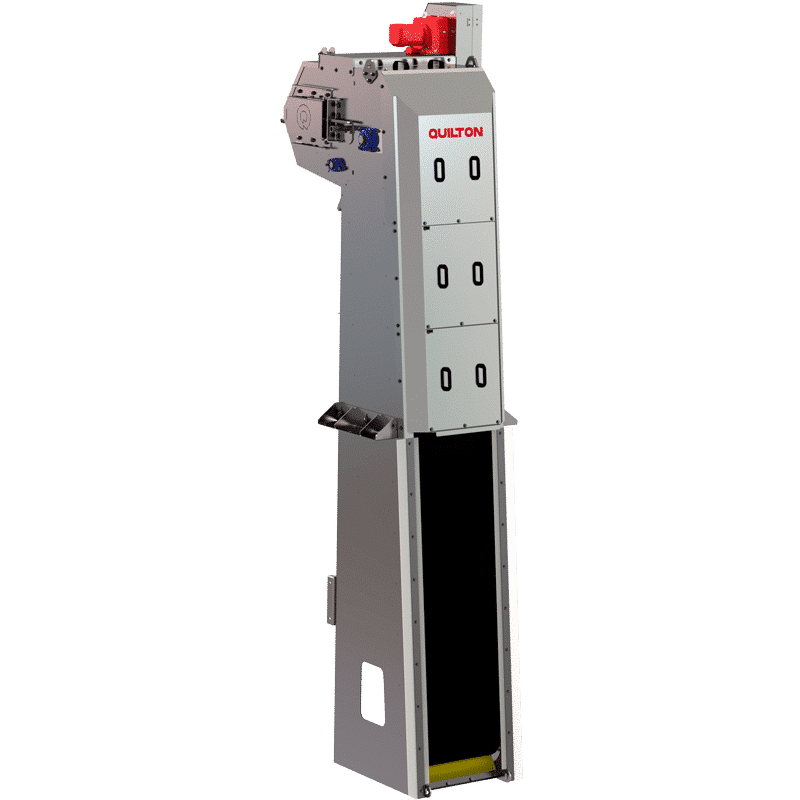

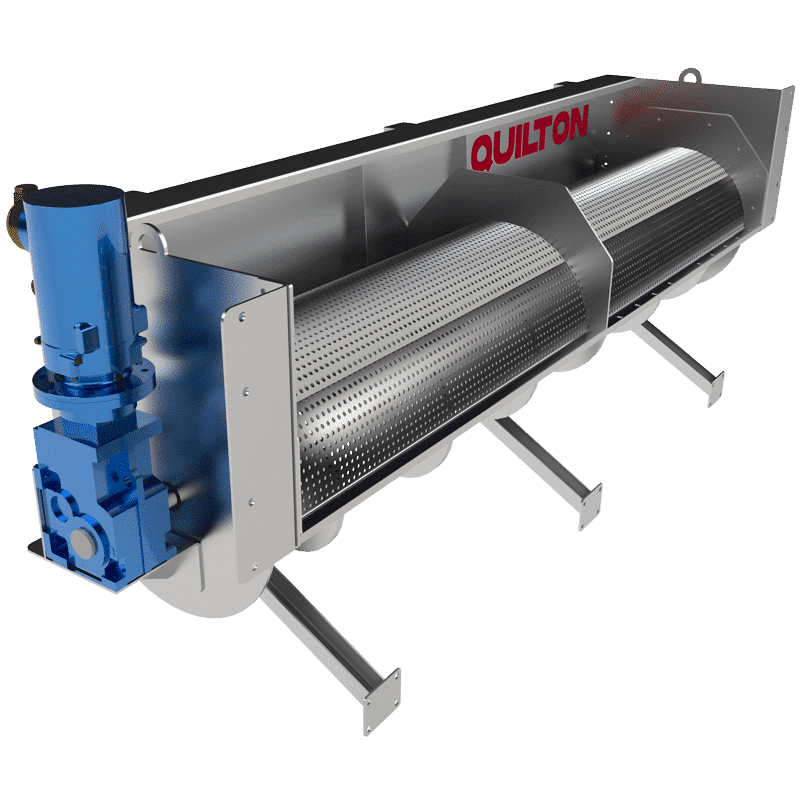

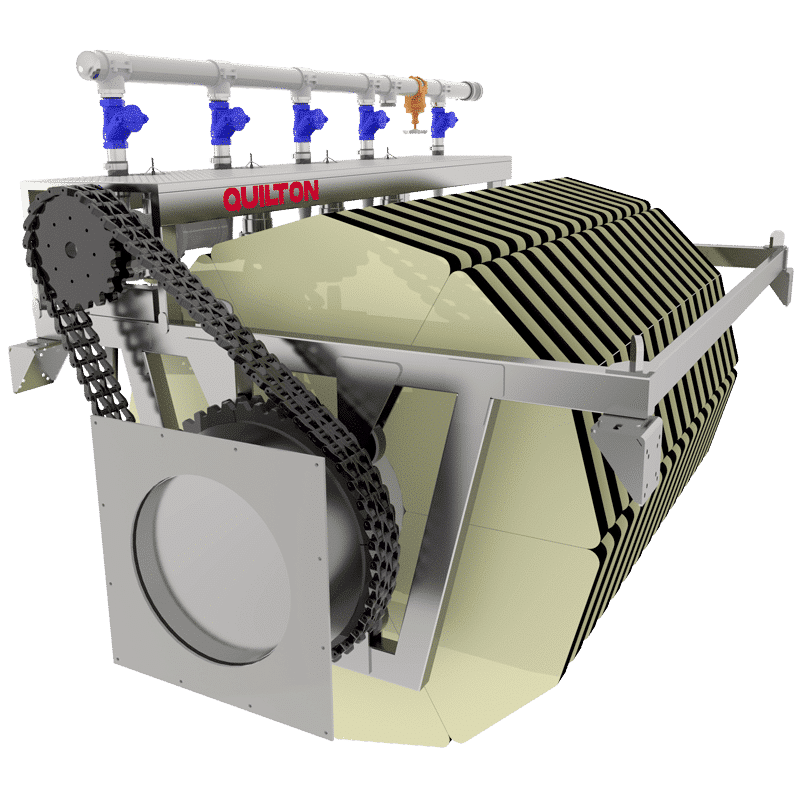

Rotary drum screen

Screens

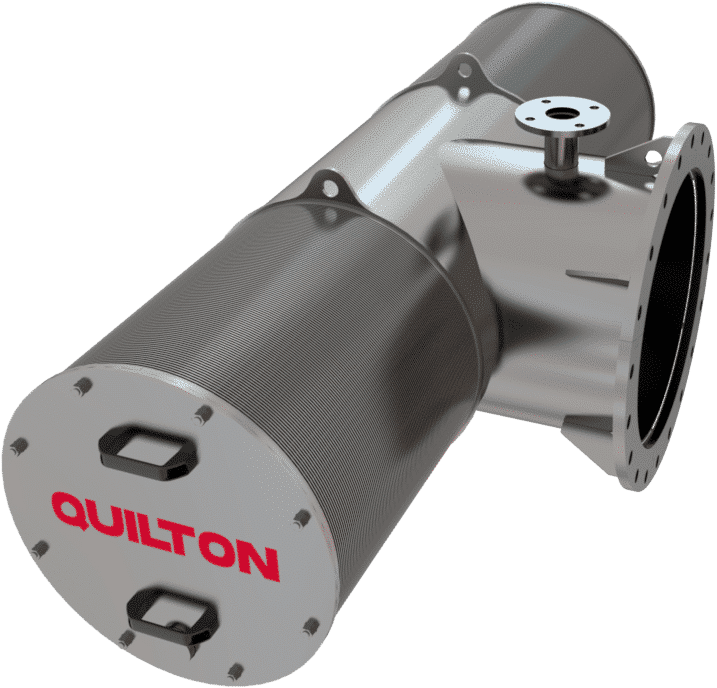

The QUILTON rotary drum screen is a self-cleaning rotary drum screen that can be operated continuously and is used for filtering waters and liquids from different sources.

These liquids are normally heavily loaded, so the rotary drum screen or sieve separates and removes any solids in suspension that are larger than its spacing.

The rotary drum screen has a cylindrical grille on a horizontal shaft, consisting of trapezoidal stainless-steel bars and rotating slowly. The floating materials larger than its spacing are retained by the grille and removed by a fixed scraper.

Features and structure

Operation

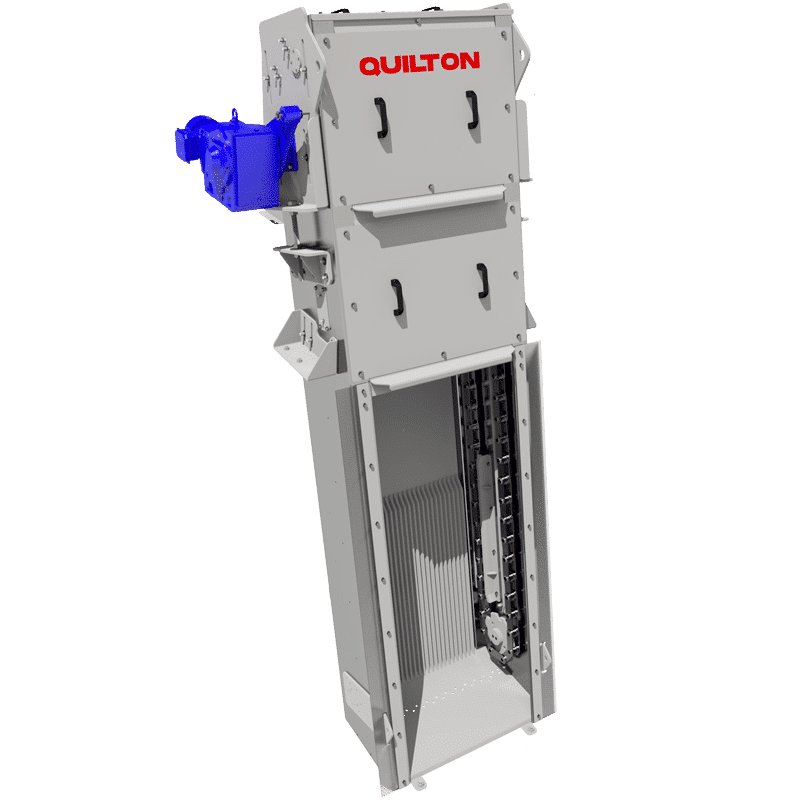

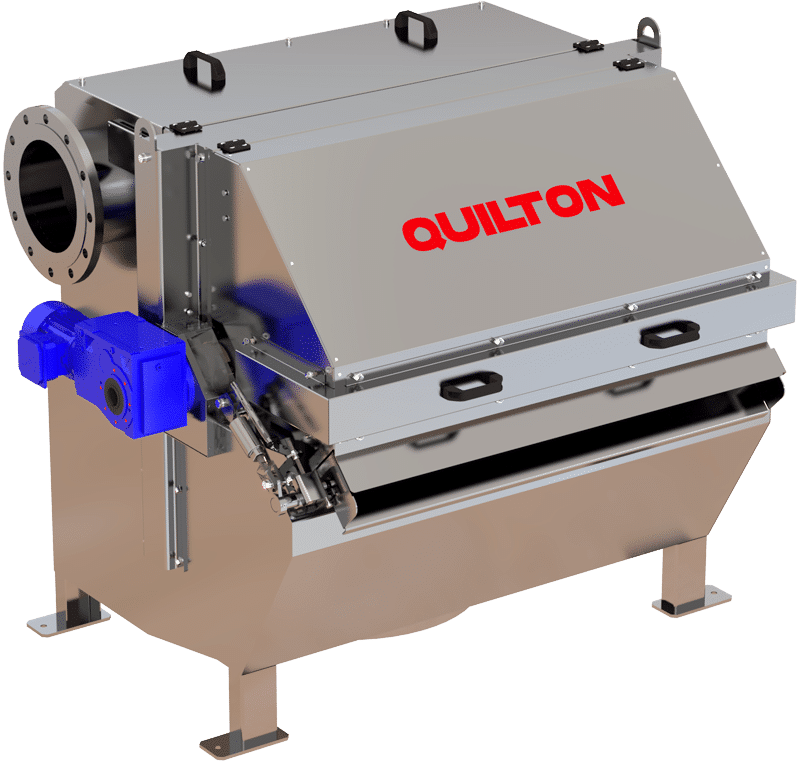

The water to be screened is either pumped or drawn by gravity through the inlet flange. The inlet pipe on the rotary screen is connected to the inlet flange in the distribution area, where the water reaches and comes into contact with the rotary drum though its distribution chamber, which spreads the water all along the filtering drum.

The water passes through the V-shaped profiles that form the drum while any solids larger than the spacing on the lattice are retained on its surface. These solids are carried by the drum as it turns until they are removed by a scraper, which rests on the length of the drum and facilitates the discharge of the wastes.

This scraper, located on the opposite side from the inlet, is in permanent contact with the drum along its entire length thanks to the pressure exerted by a spring, which also compensates automatically for any wear.

The clean, filtered water passes through the lower part of the screen through the V-shaped profiles, now free of solids but still containing the particles that have not been removed by the scraper. The filtered water leaves the QUILTON rotary drum screen through the chamber for collecting filtered water, located in the lower part, via a flanged connection. It is also fitted with emergency outlet and emptying flanges.

The filtering drum consists of V-shaped wire, forming a helicoidal coil that is electro-welded to a chassis that has been specially designed for this purpose. The welding points on the wires and supports ensure a rigid structure that is extremely strong. There is almost no risk of clogging or obstruction thanks to the V-shaped spacing between wires that does not allow for more than two points of contact with the particles.

The scraper or blade may be made of brass, copper, bronze or plastic so as not to damage the stainless-steel drum. The pressure and contact between the two components are achieved through the action and force of a system that allows for the manual adjustment of the scraper pressure.

The system for washing and cleaning the lattice on the rotary drum screen consists of a pipe, fitted with evenly spaced spray nozzles, located along the entire length of the drum.

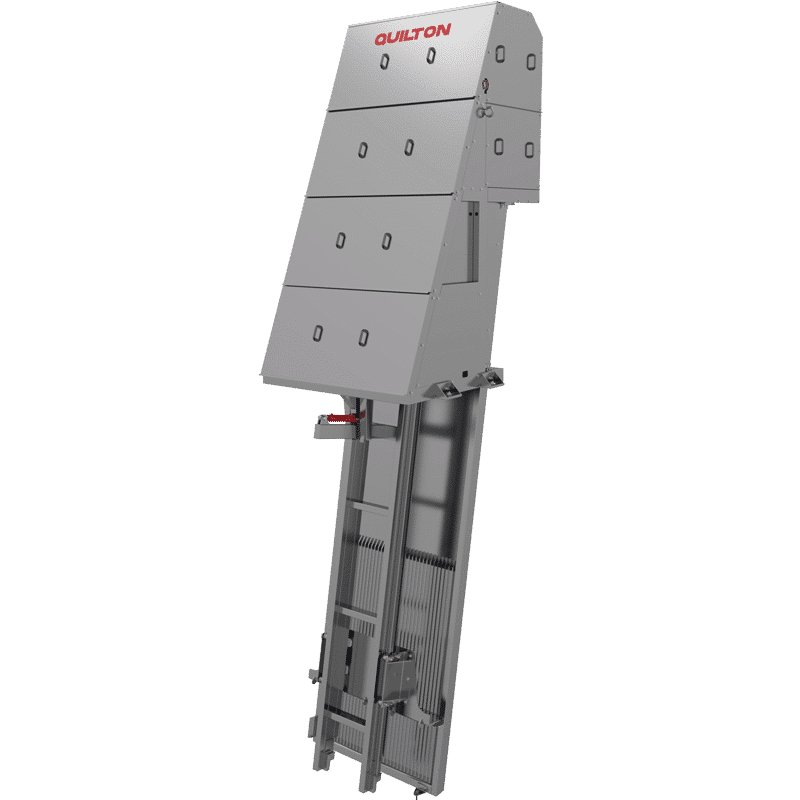

Options in assembly and maintenance

ADVANTAGES OF THE ROTARY DRUM SCREEN

- There is almost no risk of clogging or blockage thanks to the V-shaped wire that makes up the filter drum. This means the equipment’s hydraulic capacity can be increased with a minimal pressure drop.

- Minimum costs, as the entire drum unit consists of separately mounted components to facilitate maintenance and replacement of individual parts.

- It has a system for manually adjusting the scraper pressure.

- The front cover has a pneumatic fast-opening system for facilitating inspection work.

- It is a self-cleaning rotary screen that operates with minimum maintenance.

USES OF THE ROTARY DRUM SCREEN

Urban wastewaters for screening:

- Fine particles and sludges.

- Rainwater and outfalls.

Industrial effluents from:

- Poultry and meat abattoirs.

- Processing and precooked industries.

- Laundry, textiles and tanning.

- Sugar mills, breweries and wineries.

- Chemicals and pharmaceuticals.

- Cellulose and paper.

Rainwater drains for:

- Industrial uses.

- Irrigation sprinklers and fire hydrants.

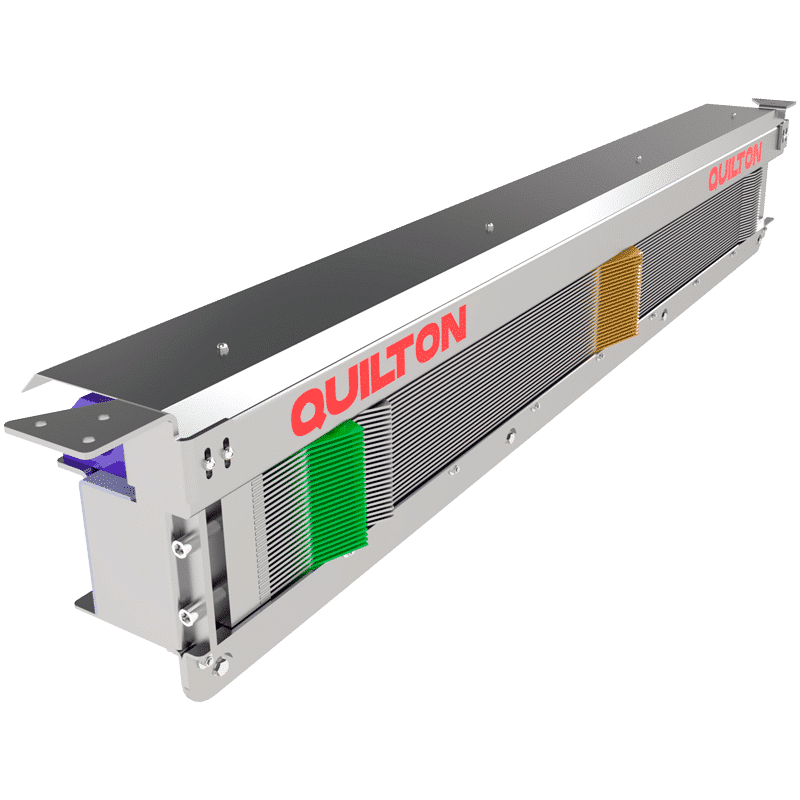

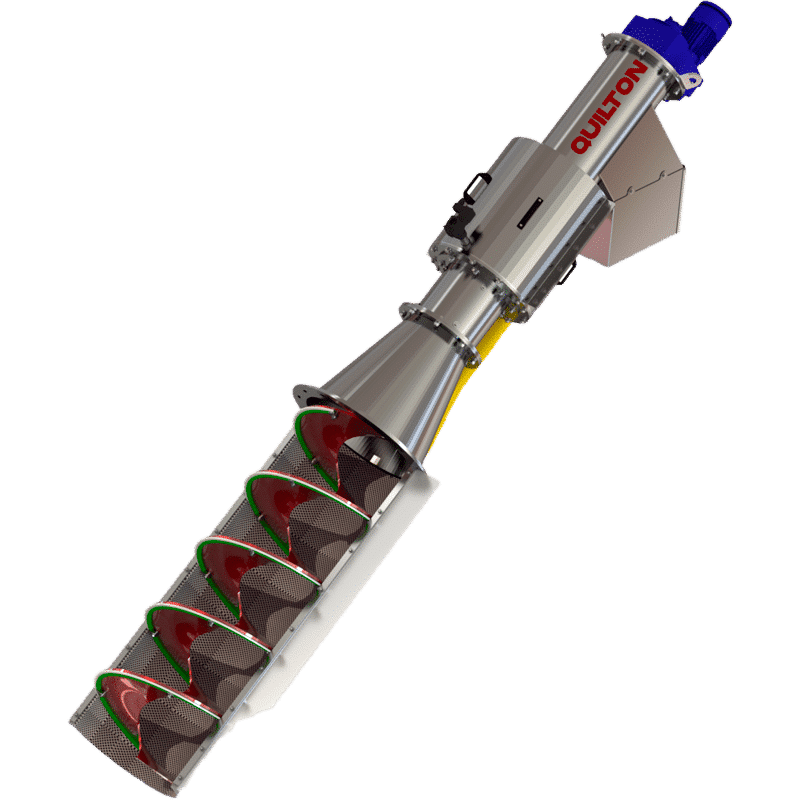

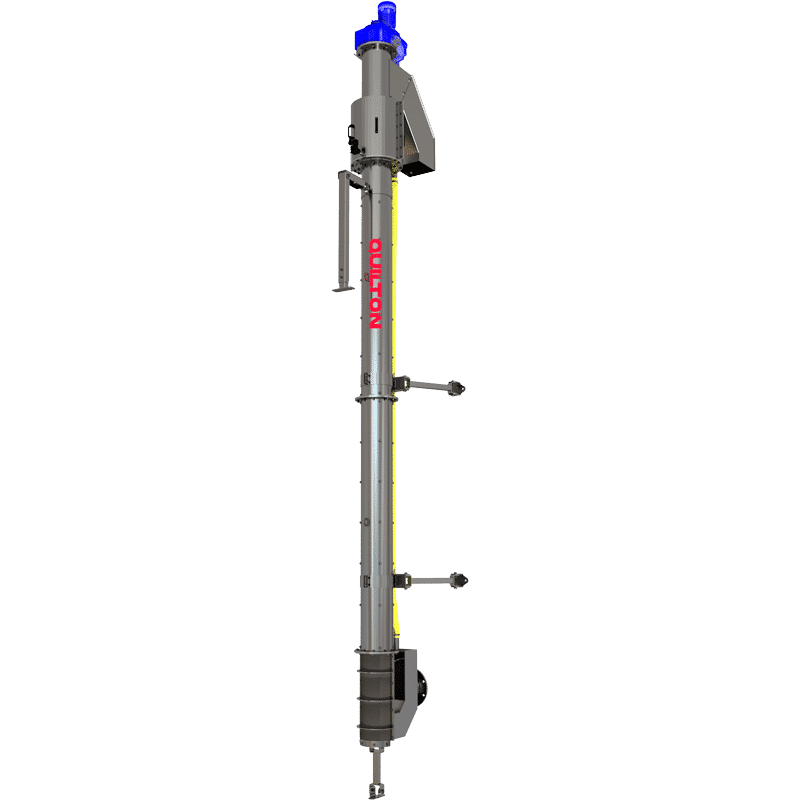

OTHER EQUIPMENT

Related equipment