This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

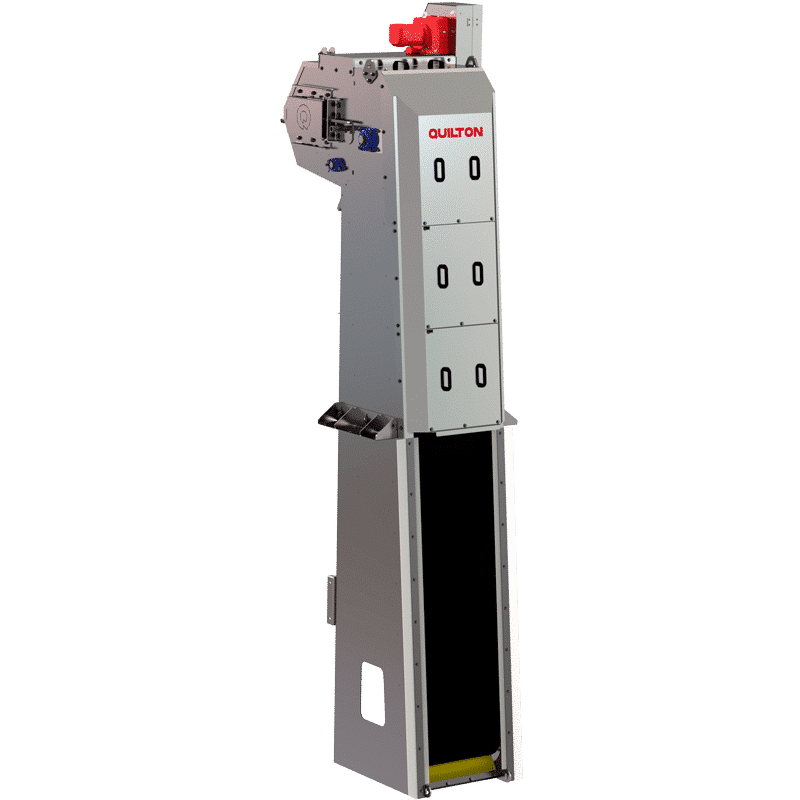

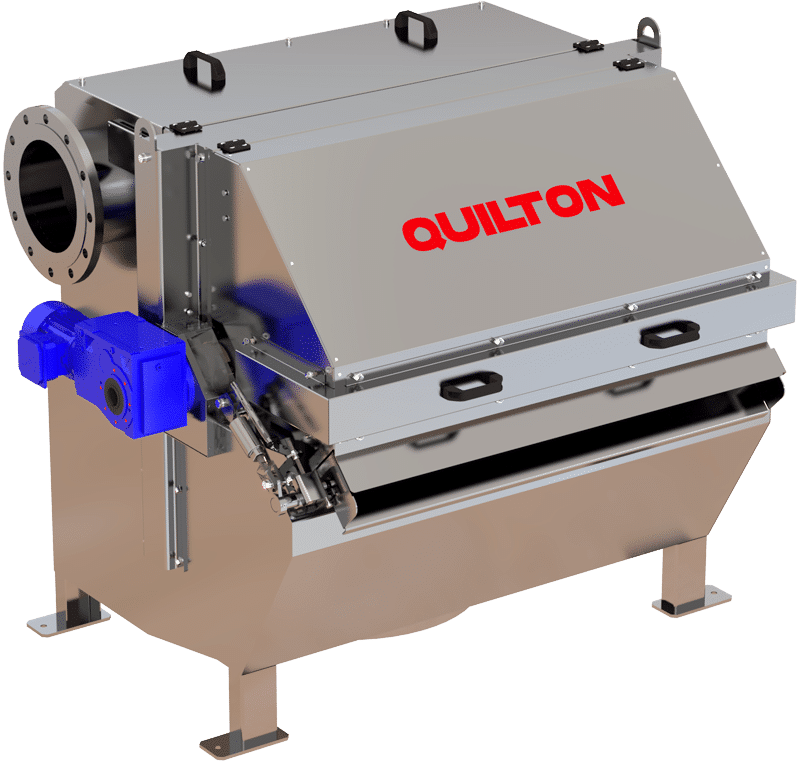

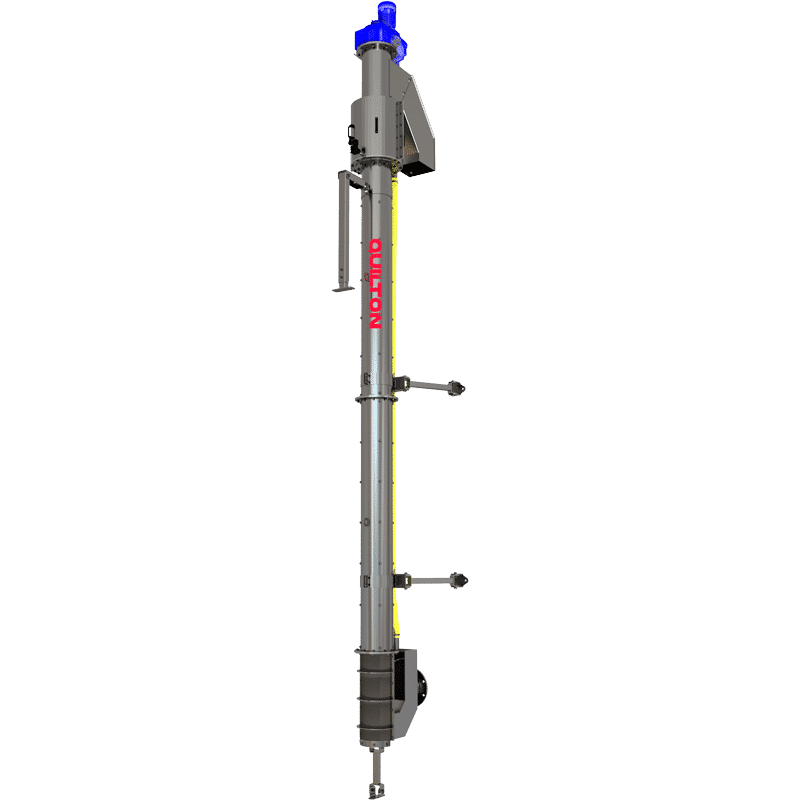

Vertical screw screen

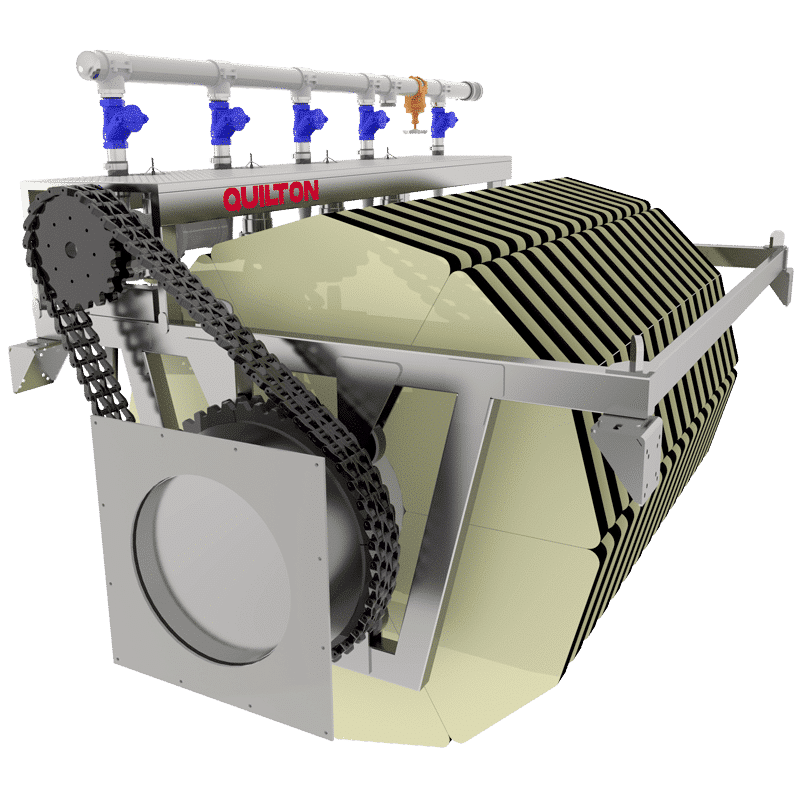

Screens

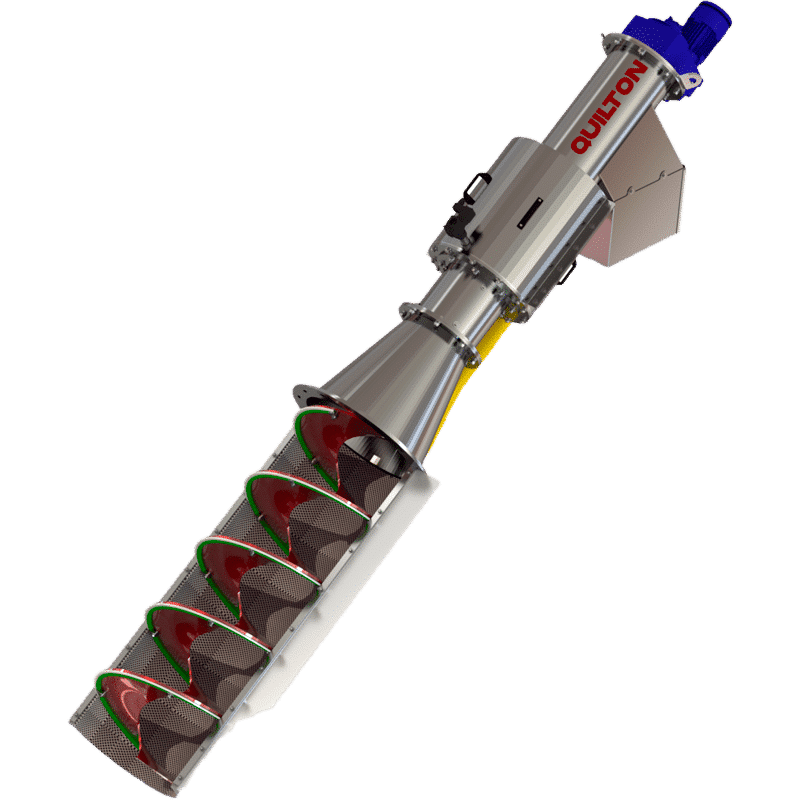

The vertical screw screen is used to separate the solids in wastewaters for their subsequent compacting and dehydration, with a view to resolving issues related to the pre-treatment of wastewaters; especially before pumping operations.

The spacing on the equipment’s lattice ranges in thickness from 2 mm to 10 mm. The main shaft has different shaped whorls, spacings, and angles for improving their conveyance and compacting.

Features and structure

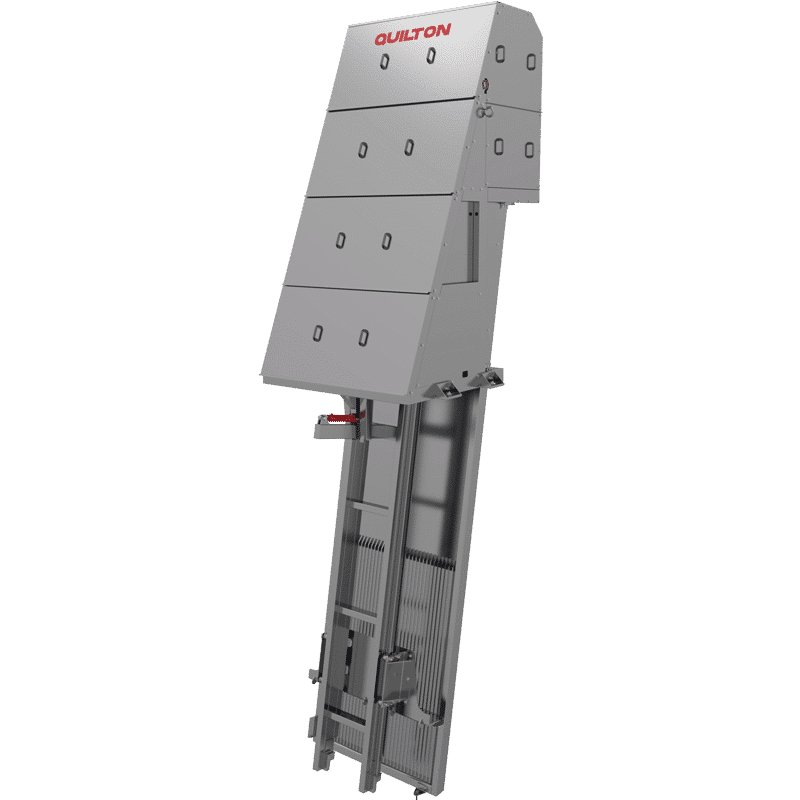

The wastewater flows into the receiving chamber, which is an uncovered rectangular construction that serves as an emergency overflow tank in the event of a power outage, excess flow, and/or the clogging of solids.

A rectangular opening on the lower part of the receiving chamber connects it to the screening basket, and those solids larger than the spacing are retained while the water is drawn by gravity through the holes on the screen’s perforated section and in the filtering area.

The solids are retained in the screen’s filtering area, which is cleaned by the brush mounted on the spiral, which at the same time moves the retained wastes in an upward direction and compacts them in its end zone.

As the wastes are being raised, they are dehydrated and compacted before being discharged into a skip. The liquid from the pressing process (drainage) is collected and returned to the screening basket through a flexible hose.

The QUILTON vertical screw screen has the following structural and mechanical features:

- 90º angle of positioning.

- Type of materials: stainless steels AISI-304, AISI-316, duplex 2205, super duplex 2507, etc.

- Fully automatic operation.

- Totally enclosed discharge trough.

- Bagging unit (optional) that avoids the emission of odours from compacted wastes.

- Completely hermetic from the screening area. through to the discharge trough.

- Overflow included in the screening area.

- Brush on the spiral for the self-cleaning of the screening area.

Operation

Components

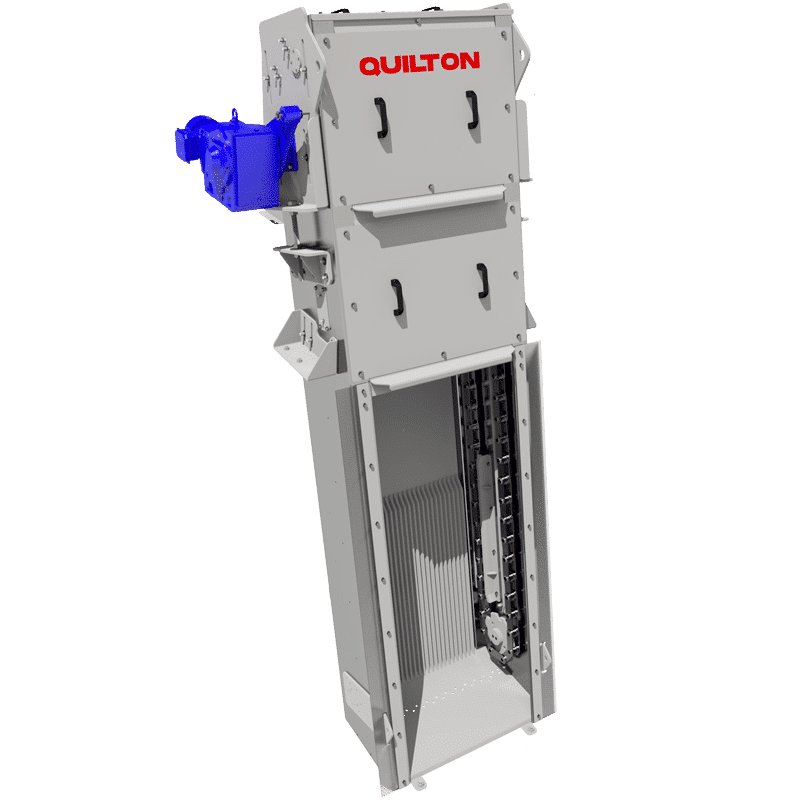

The vertical screw screen is basically made up of four parts:

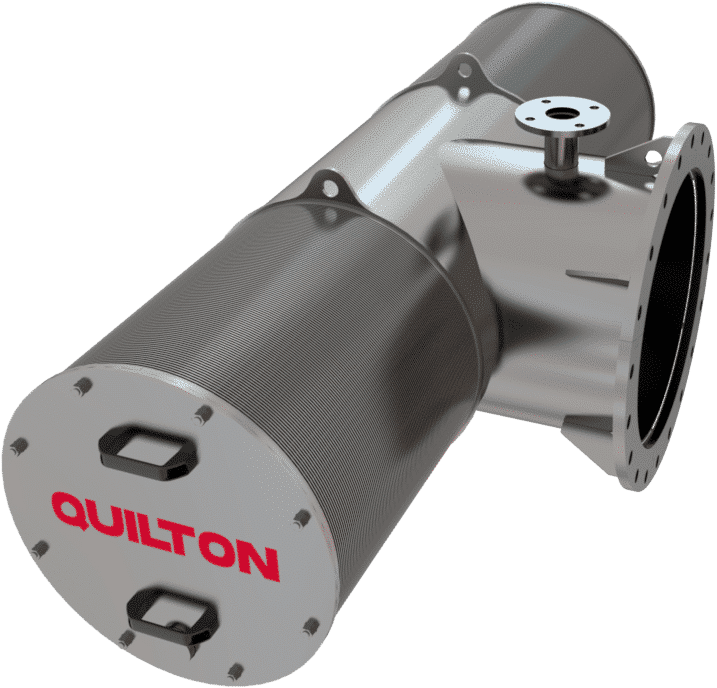

- Filtering area: this is the part of the vertical screw screen that is connected to the inlet channel through which the wastewaters flow. It consists of a steel screening basket with perforations (2-6 mm in diameter) and a spiral with a brush on its lower end to provide continuous cleaning of the screening basket.

- Waste transport or lifting area: this is the middle part between the filtering and discharge areas. It involves a tubular trough and a conveyor auger with a main shaft installed at an angle of 90º.

- Pre-compacting and compacting area: this is the last and highest part of the auger, and as its name indicates, it is the area where the screened solids are moved, washed and compacted by the extraction screw. It leads to the discharge trough.

- Operation: this involves a low-rev gear motor mounted on the top of the unit.

The water passes through the basket, which is fixed in place, and when the water level reaches a pre-set value the gear motor begins operating and the screw begins extracting the waste. The equipment’s design ensures that no solids larger than the spacing are drawn through it.

The compacting area basically consists of a section without a spiral where the product is moved slowly. At the outlet, the tubular body has a reverse spiral and a blade for removing roughed solids. Depending on their nature, the volume of incoming wastes is reduced by between 30 and 50% once compacted, provided the degree of filling is 20-30%.

ADVANTAGES OF THE VERTICAL SCREW SCREEN

- Simple and robust design.

- Straightforward to install.

- Suitable for small spaces.

- Minimal operating and maintenance costs.

- Low energy consumption.

- Readily adaptable to variable operating conditions.

- No additional cleaning systems.

- Suitable for outdoor operation.

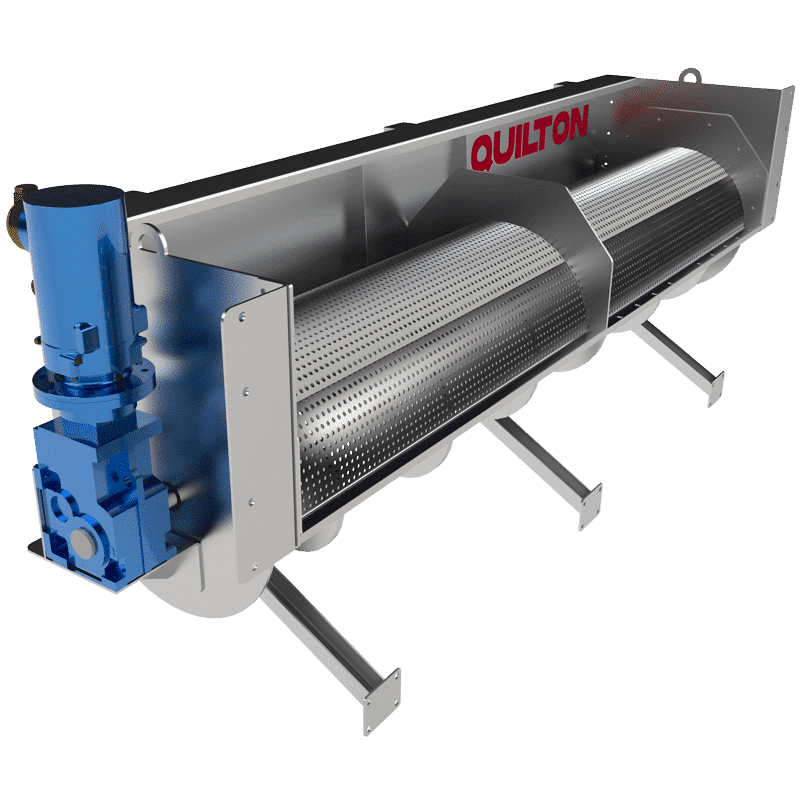

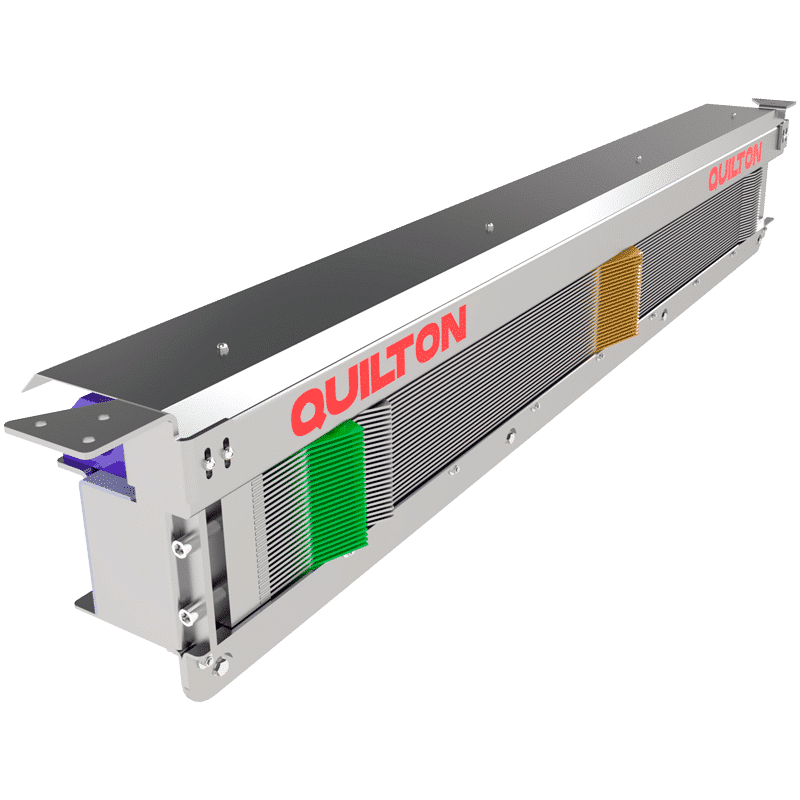

OTHER EQUIPMENT

Related equipment