This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

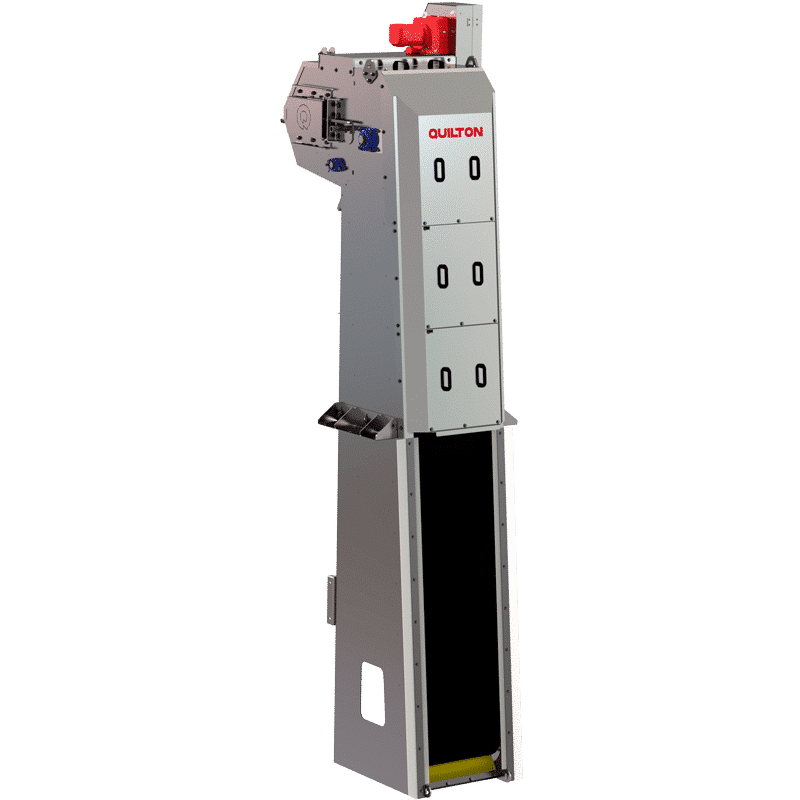

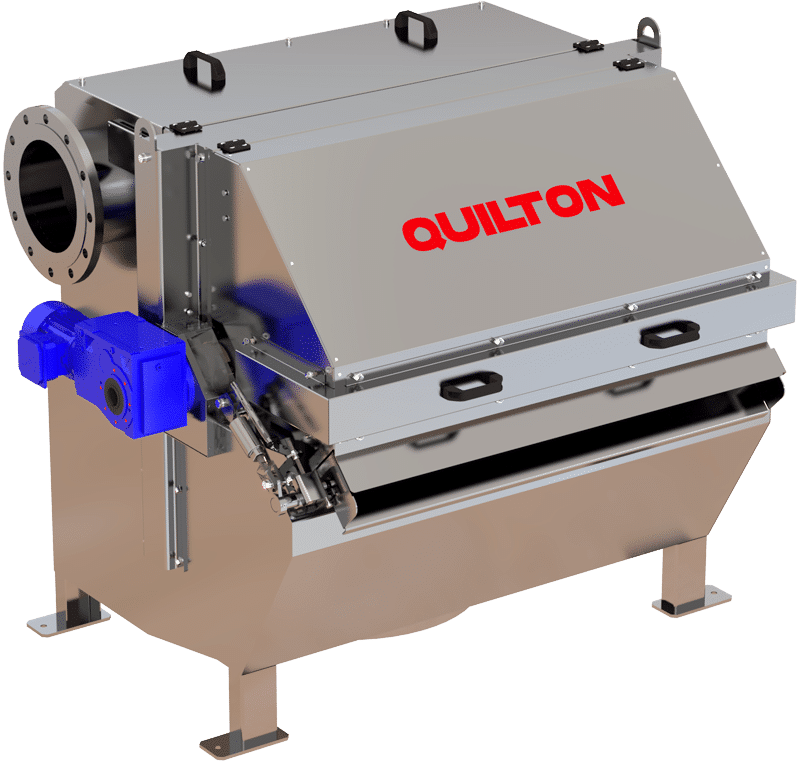

Static screen

Screens

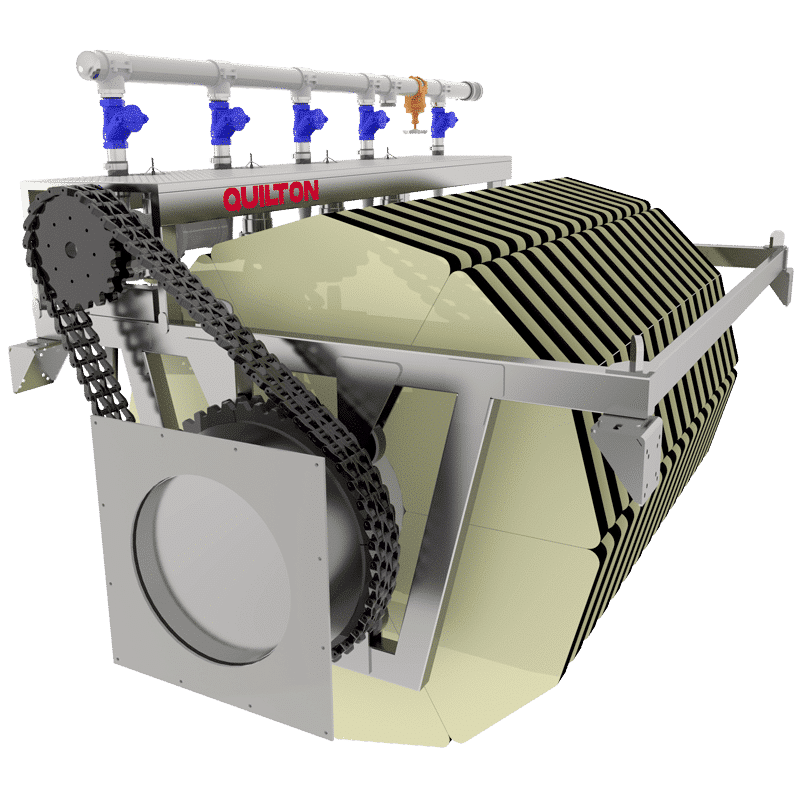

The QUILTON static screen is designed for solid/liquid separation based on the Coandă effect. The direction of the water is tangential to the direction of the opening on the lattice, based on the principle of the Coandă effect, which prompts self-cleaning. The solids larger than the spacing are retained by the grille. They slide along and are strained until they are offloaded via the discharge ramp.

The QUILTON static screen device uses a laminar, high-performance screening system. It operates either though gravity or by pumping, with the recommendation that the liquid to be screened should not arrive at pressure, as this will lead to the uneven distribution of the flow over the width of the lattice and impair the screening process.

The screen consists of a chassis body and a filtering grille. The water to be filtered passes through the openings, with any solids being retained and separated on the filtering grille.

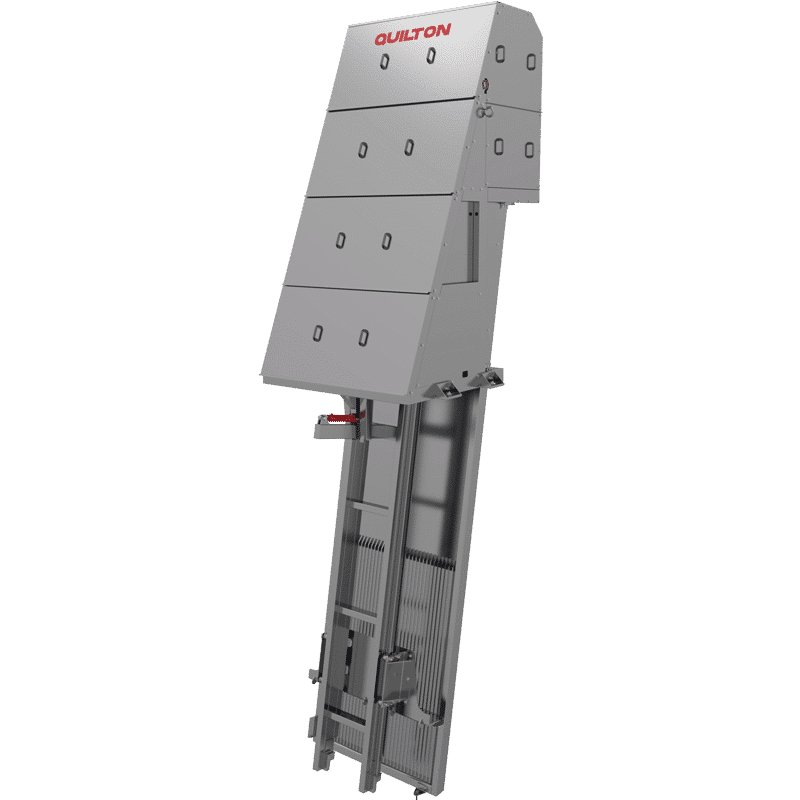

The grille, involving corrugated laminar profiles, serves two purposes: distribute the raw water to be filtered across its breadth and collect that water though the inner part of the profiles.

The static screen has a grille made of triangular-shaped horizontal stainless-steel bars that are straight or curved. The water is distributed in the upper part of the grille, whose angle over the horizontal steadily reduces in a top-down direction, between 65º and 45º approximately. This caters for the successive step of separation, drainage and removal of solid materials.

Features and structure

The QUILTON static screen basically consists of a chassis and a filtering grille. Its originality lies in the shape of the bars on the grille, which give it major advantages over static screens with straight bars.

In addition, the QUILTON static screen has three sloping sections. Two for filtering and the last one for draining. The first provides the main filtering of raw waters, followed by filtering on the second ramp, while the third performs the final draining of the solids retained by the static screen. The following are the advantages provided by the three different ramps:

- Filtering the highest volume of water.

- Retaining any solids larger than its spacing.

- Draining the solids prior to discharge.

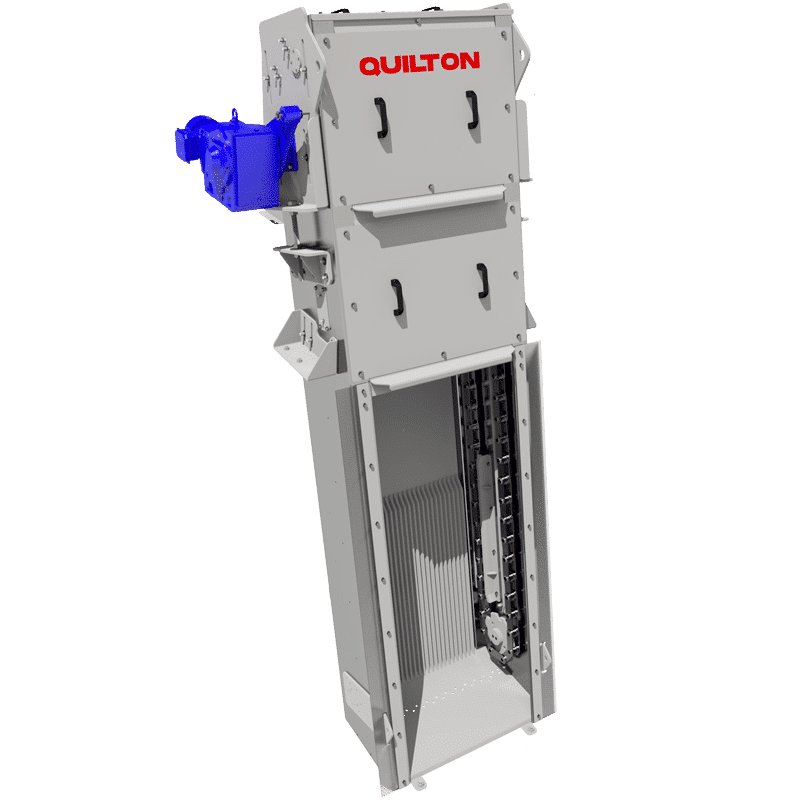

COMPONENTS

- Chassis: this component is made of stainless steel. It also doubles up as a tank, which is divided into two parts:

- The first, the upper part, is in the inlet for the liquid to be screened, where it overflows and passes into the filtering grille.

- The second, the lower part, receives the filtered liquid, where gravity draws it out through the outlet flange.

- Filtering grille: it consists of triangular corrugated laminar grilles, forming a sinusoidal grille. This filtering grille consists of three ramps, with each one sloping at a different angle.

- Covers: besides providing safety and protection, the covers on the QUILTON Static screen minimise any possible odours coming from the liquids to be screened.

- System for turning the filtering screen: the filtering grille has a shaft that enables it to turn. The turning action involves releasing the upper clips and the bolts on the discharge ramp. This allows cleaning the inner face on the filtering grille, as well accessing the lower tank for maintenance purposes.

Operation

Options in assembly and maintenance

ADVANTAGES OF THE STATIC SCREEN

- No moving parts or motor.

- Zero or minimum maintenance costs.

- Filtering surface on the grille consists of a V-shaped wire welded to supports, guaranteeing exceptional strength.

- Silent running.

- The grille has three ramps at different angles that permit it in successive steps to filter a large amount of liquid, retain solids bigger than its spacing, and drain them before their discharge.

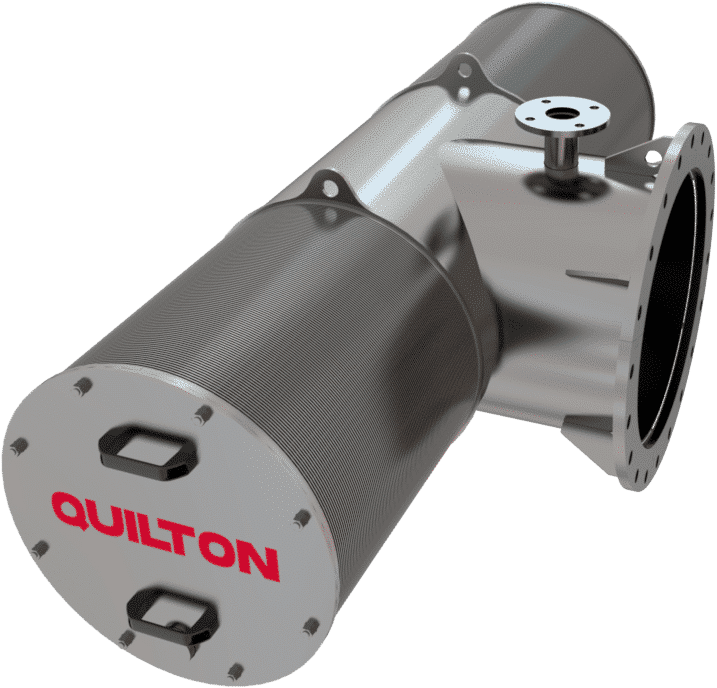

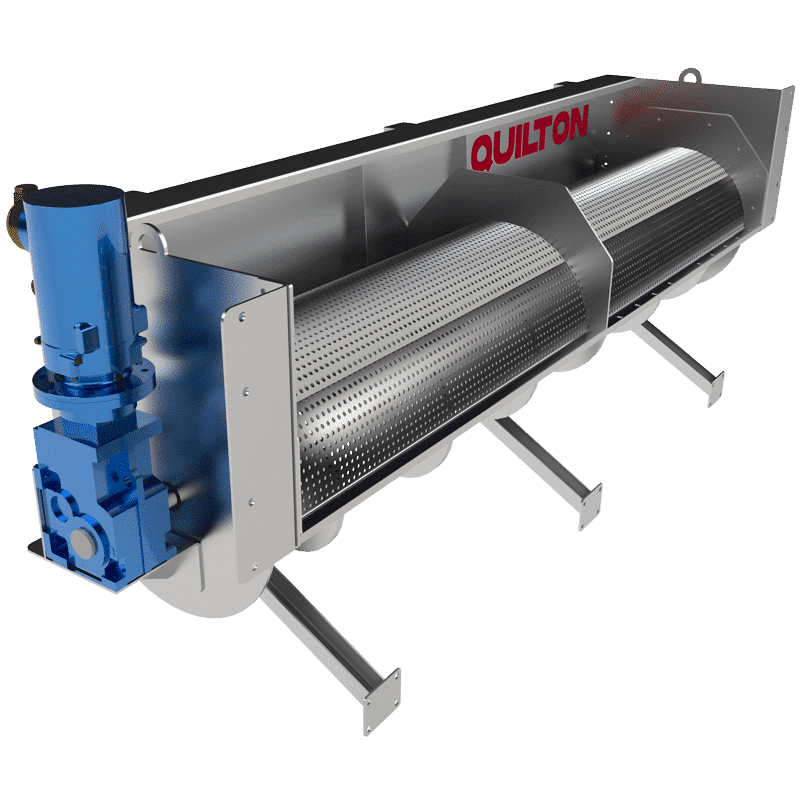

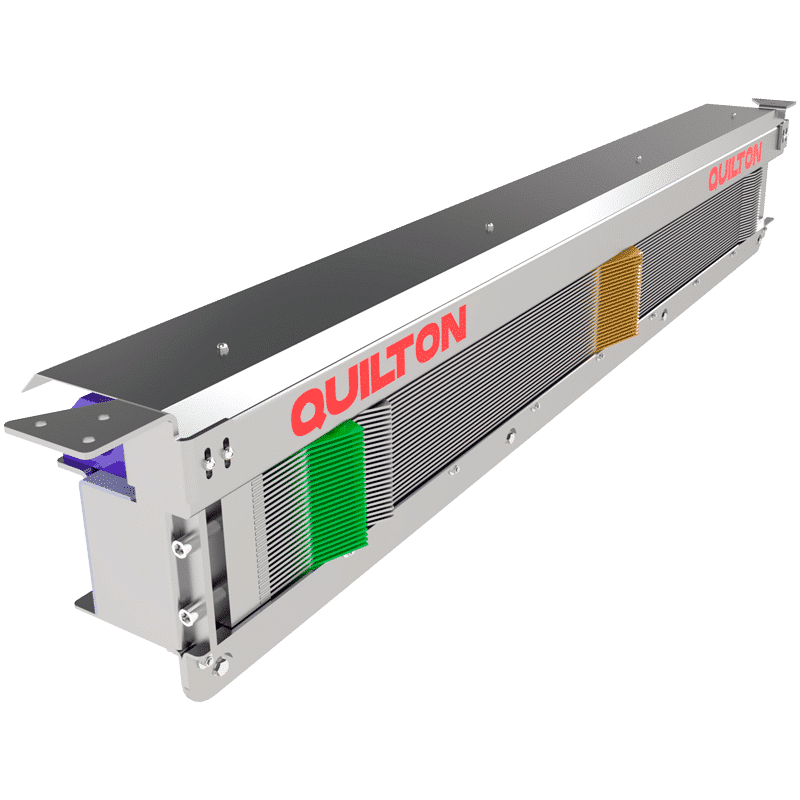

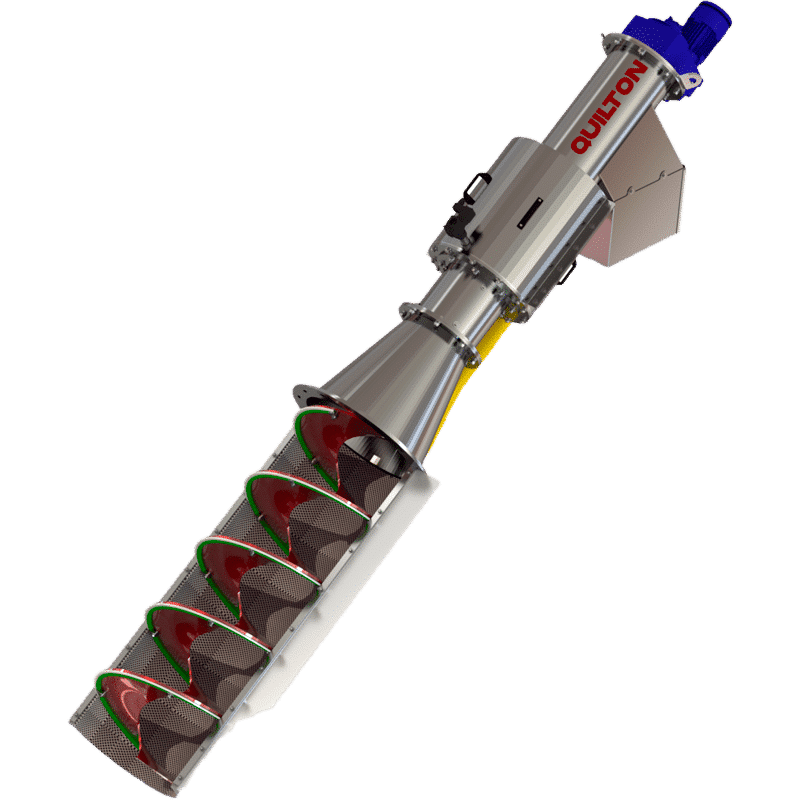

OTHER EQUIPMENT

Related equipment