This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

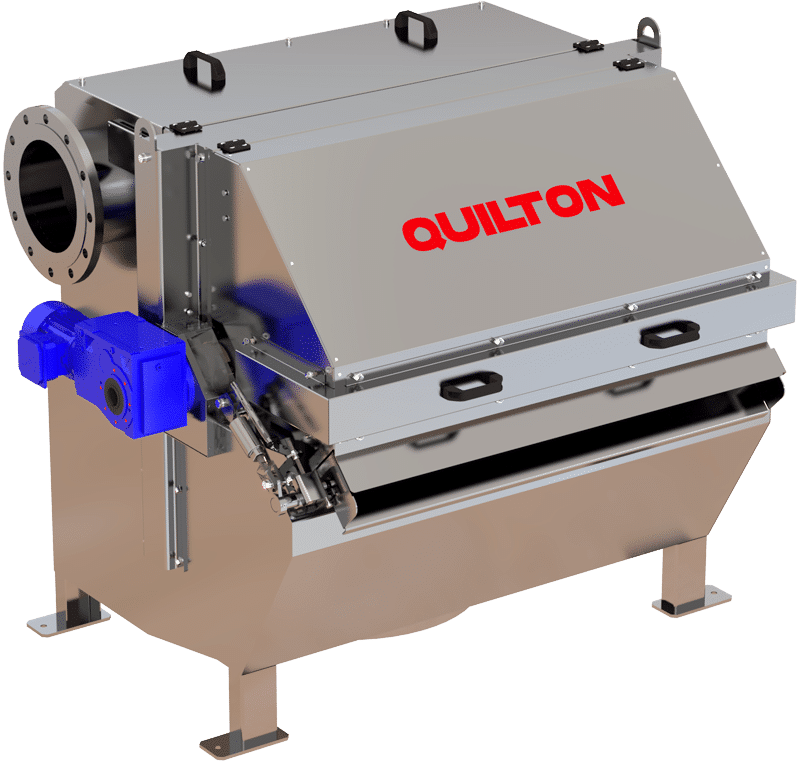

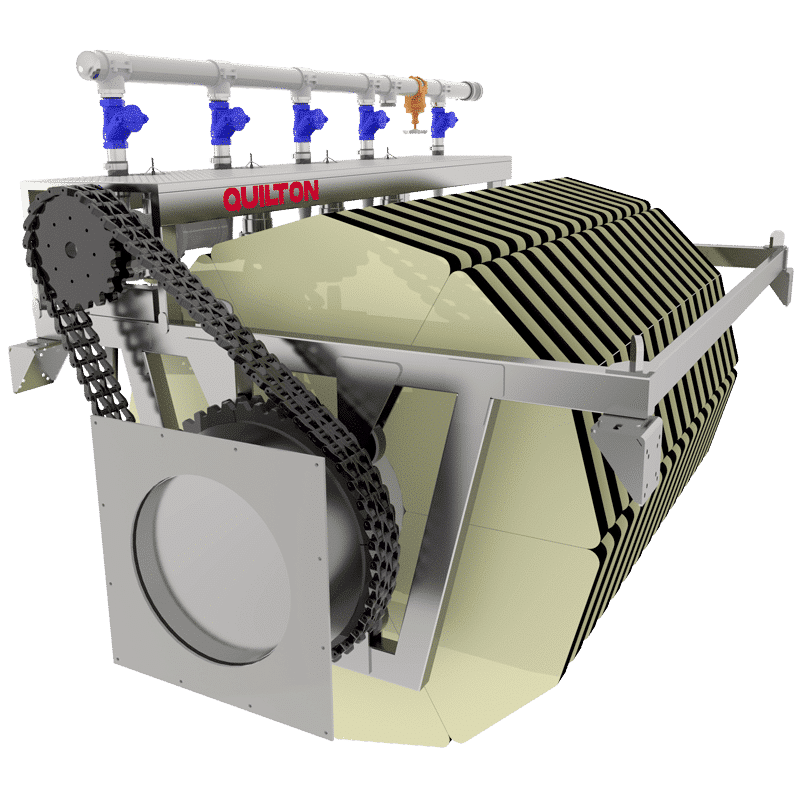

Horizontal bar storm overflow screen

Screens

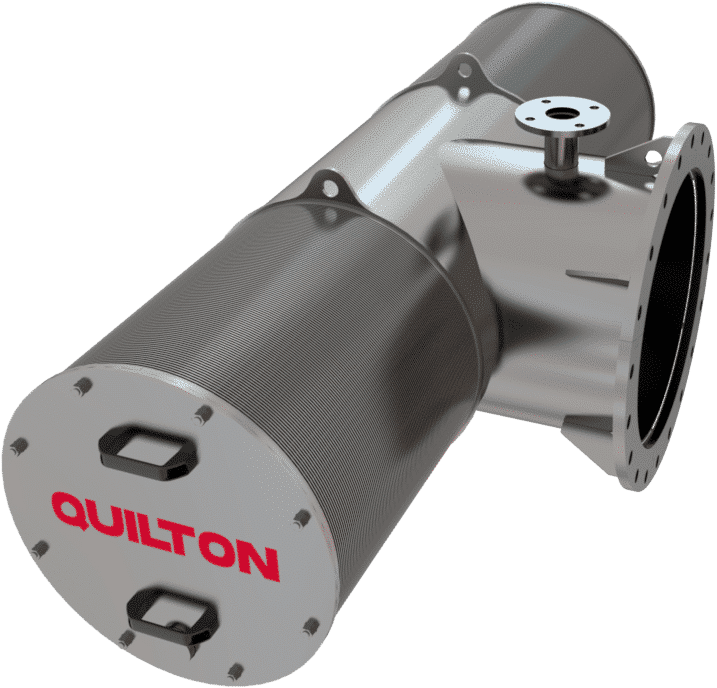

The QUILTON horizontal bar storm overflow screen is a device that retains materials larger than 3-4 mm that are floating or in suspension in a liquid overflow before being discharged into a river, lake or the sea.

This tends to be due to an excess flow, generally during long episodes of rainfall or storms. The solids retained by the screen are carried by the flow of water to a pumping station or WWTP for their subsequent treatment.

Its simple design, largely involving the slow, alternating movement of an oleohydraulic cylinder that operates a cleaning carriage, allows separating the wastes while continuously cleaning the screen. There are no electrical parts in contact with the water.

Features and structure

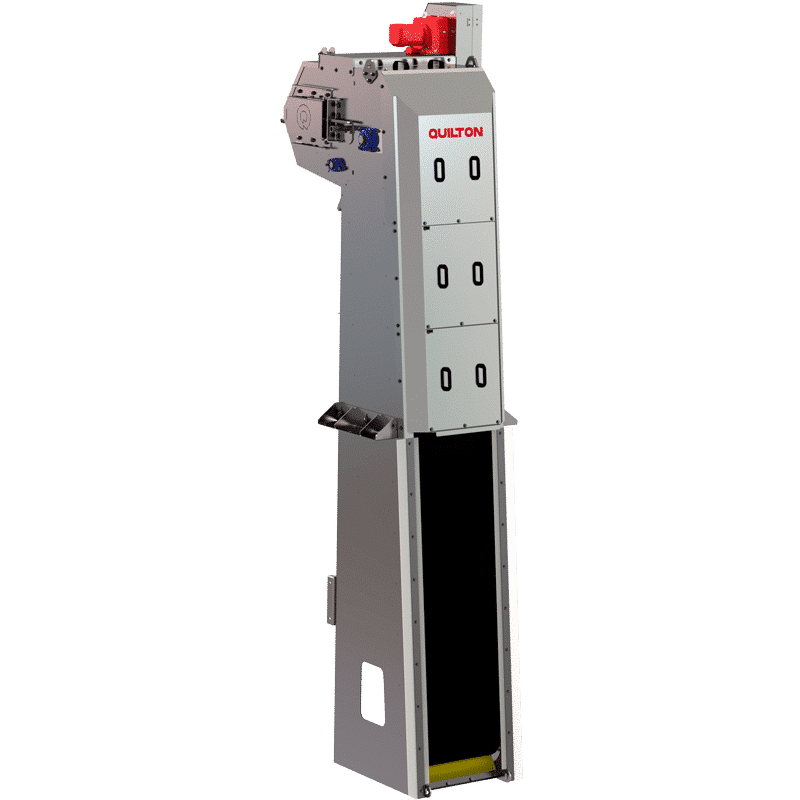

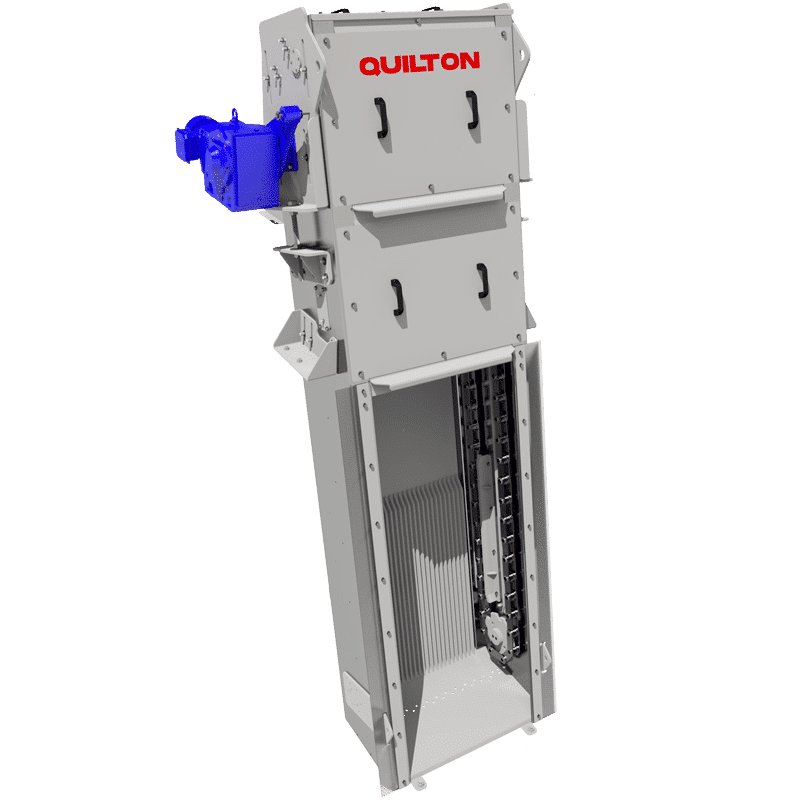

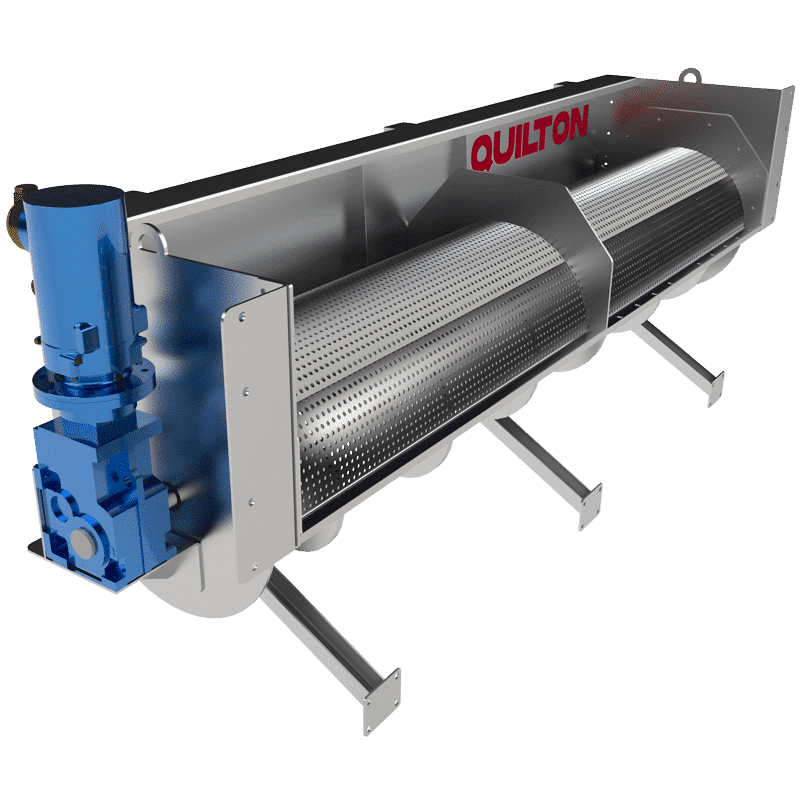

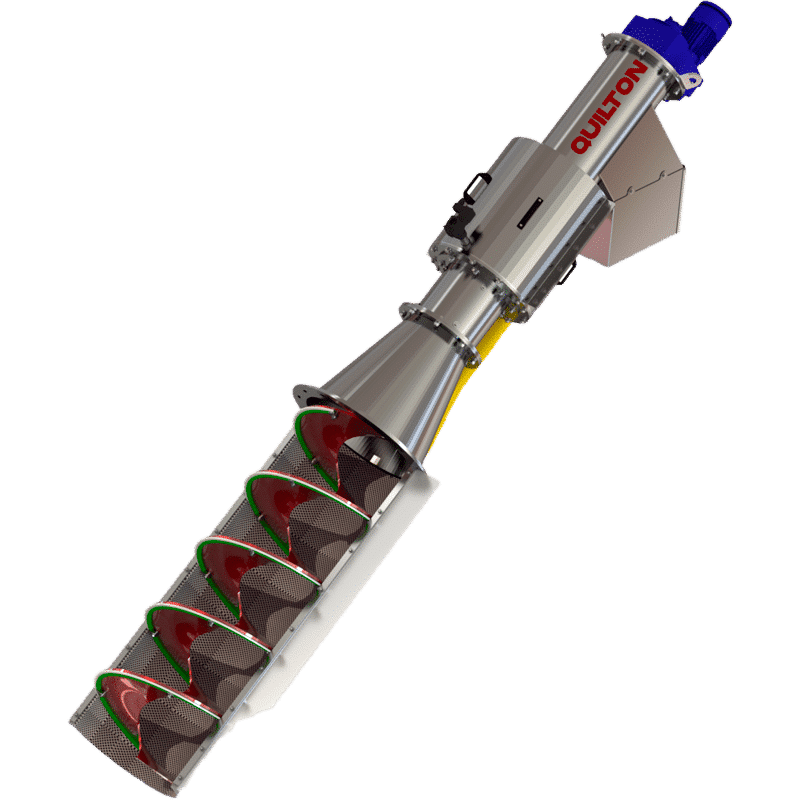

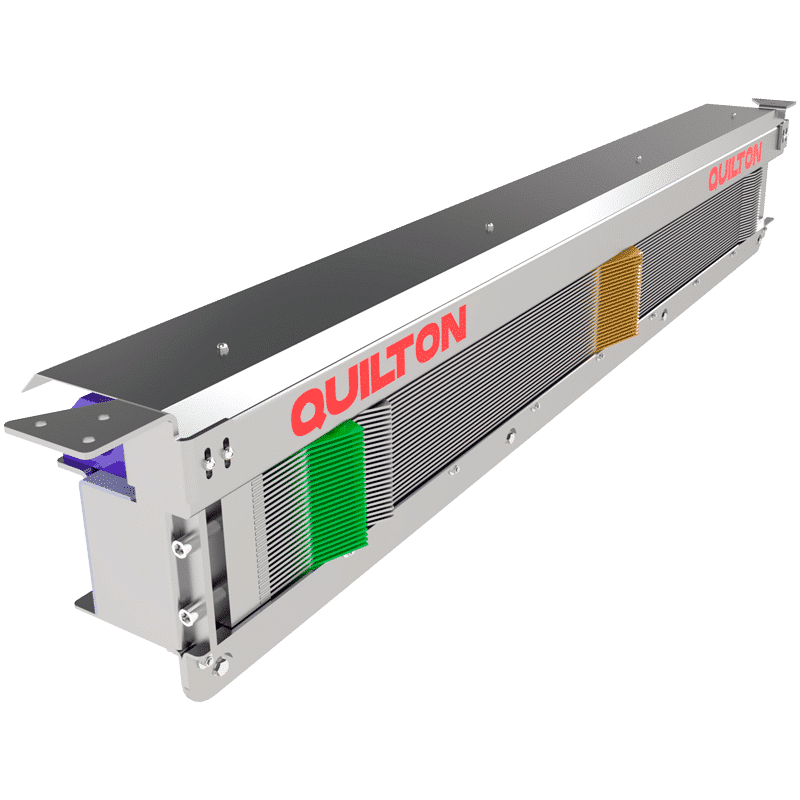

The QUILTON wastewaters-rainfall screen has a modular design. All the models have the same elements, which are assembled according to the tasks required of the model requested. The chassis structure consists of rigid square piping and folded section profiles, which are used to hold the screen, the cleaning carriages and the operating system, as well as for screening the water.

The bars on the screen’s filtering surface are made of pre-stressed stainless steel. This pre-stressing means they are only subjected to traction outside the operating area. This allows using narrow bars, thereby making optimum use of the screen surface.

These bars have a 4-mm spacing, which means the screen retains any solids in the water that are larger than 4 mm.

FEATURES

- The separation of wastes and the cleaning of the horizontal bar screen are performed simultaneously thanks to the slow, alternating movement of an oleohydraulic cylinder that operates a cleaning carriage.

- The carriage is fitted with cleaning combs and pre-stressed bars with a triangular design, thanks to which the screen is cleaned in both directions although, by contrast, the solids retained are removed only when moving in the same direction as the current of water.

- All the elements on the QUILTON horizontal bar screen for overflow channels in contact with the water are made of pickled and passivated stainless steel.

Operation

Thanks to the design of the pre-stressed bars (and their triangular shape at both ends) and the combs, the screen is cleaned in both directions although, by contrast, the solids retained are removed only when moving in the same direction as the current of water. This means any floating solids are carried to the WWTP by the current itself.

Other applications

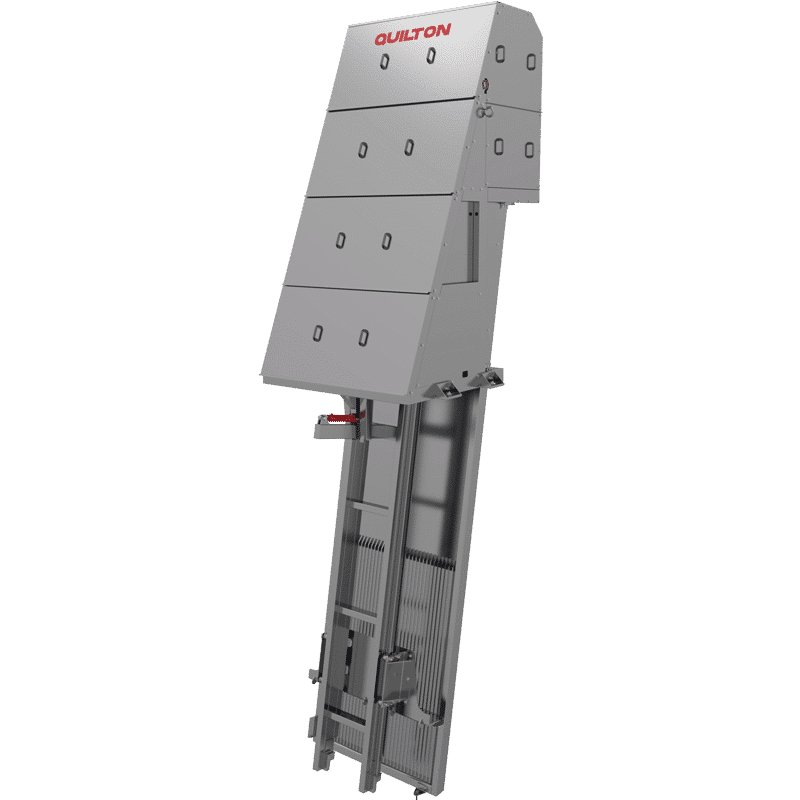

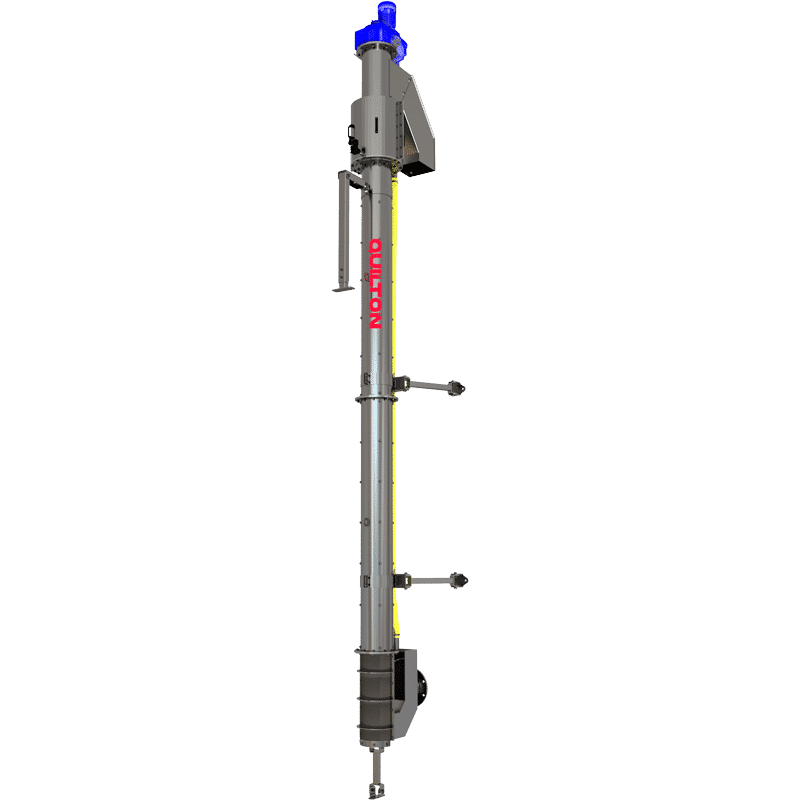

There are installations that need to vary the initiation point for the overflow. In this case, it would be expedient to include a model K horizontal bar screen for overflow channels, which also has hydraulic cylinders at the end. This is very useful in the following cases:

- Installations designed to control and vary the flow of overflow water.

- When the overflow channel is to be used for storage purposes.

- Points at which an increase in the level of the sea or river may lead to a backflow into the overflow channel.

ADVANTAGES OF THE HORIZONTAL BAR STORM OVERFLOW SCREEN

- Very safe operation.

- Solidly and robustly built.

- Minimum maintenance.

- Protects the environment against pollution.

- Automatic cleaning.

- Resistance to corrosion, as it is made of stainless steel AISI 316.

- Minimal pressure drop.

- No submerged operating parts.

- Modular system, customisable to each customer’s requirements.

OTHER EQUIPMENT

Related equipment