This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

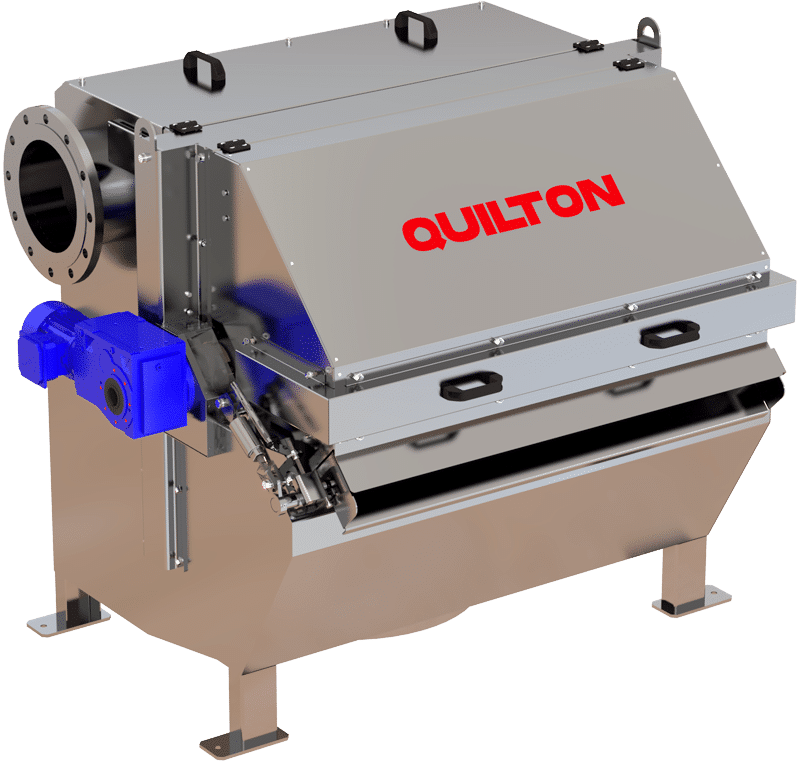

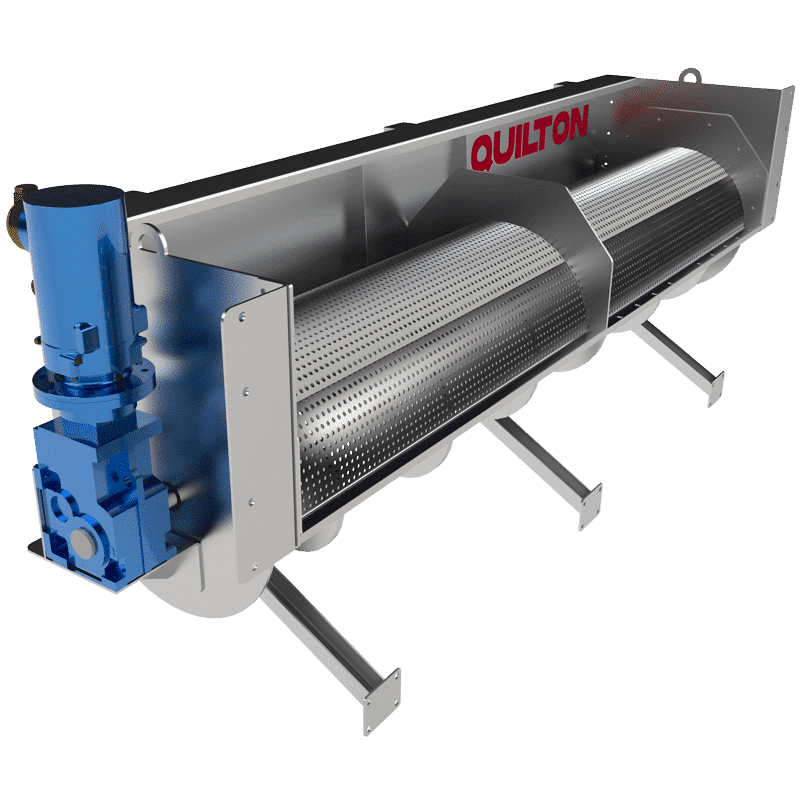

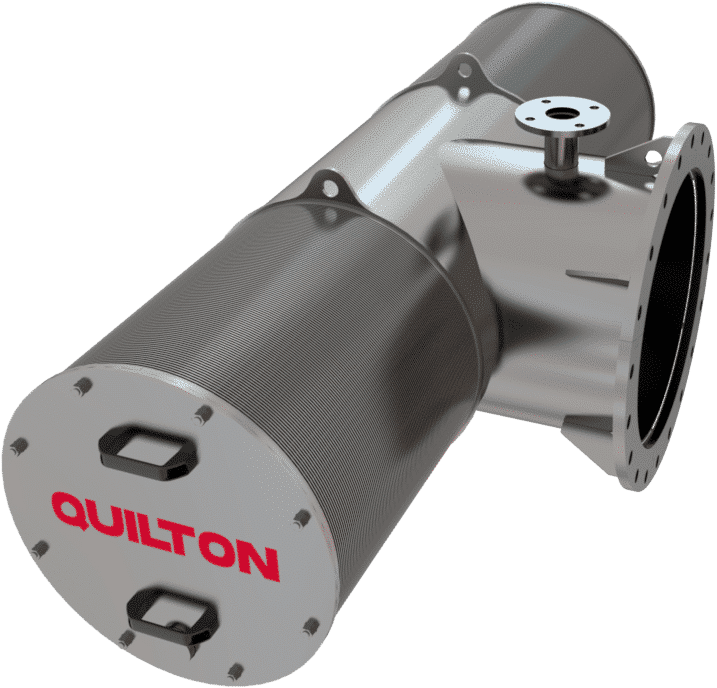

Passive intake screen

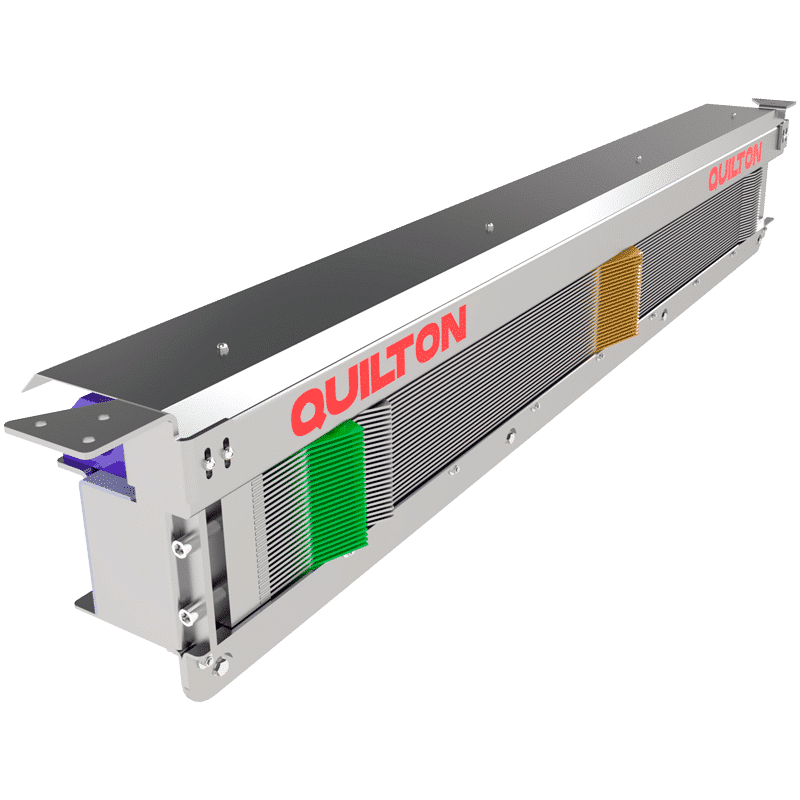

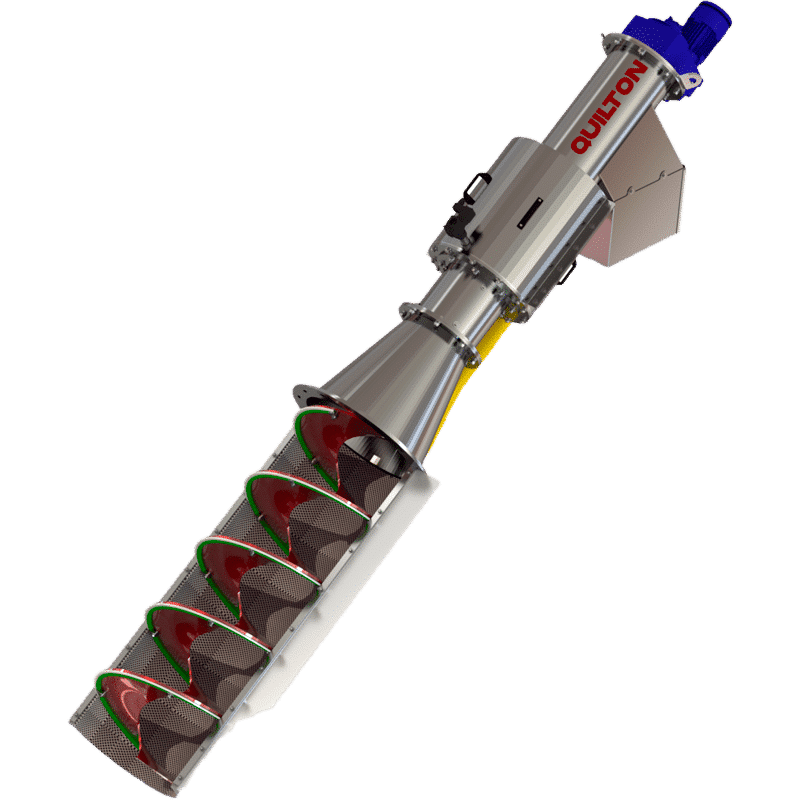

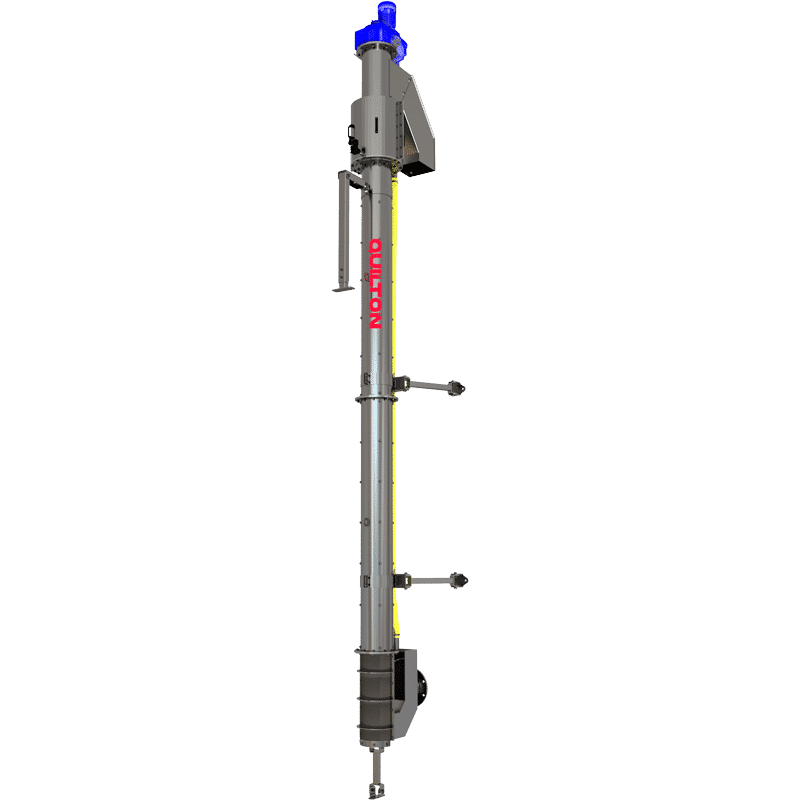

Filters

The QUILTON passive intake screen is designed to capture water from rivers, lakes, reservoirs, and the sea, with no visual impact. It consists of a submergible static filter that has no moving parts and is made of stainless steel. Its plain, smooth surface is made up of V-shaped profiles and its low suction speed means it only requires a small inlet diameter.

The spacing is normally between 1 mm and 10 mm, depending on the installation’s requirements.

Features and structure

The QUILTON passive intake screen is designed so that the inflow speed does not exceed a maximum of 0.15 m/s, with the aim being to minimise the entrainment of solids and comply with US EPA regulations. The weak effect of the suction around the static filter on the passive intake screen has a minimal impact on fauna and flora.

The large open surface on the passive intake screen means the water to be captured flows through its openings without causing any turbulence, and its installation in parallel to the current allows solids to pass by with being deposited on the surface of the passive intake screen.

The even distribution of this suction is guaranteed by its shape, the modulator pipe, and an appropriate filtering length.

The passive intake screen is cleaned by injecting high-pressure air against the current within the intake. It has an air distributor inside and along the length of the intake for this purpose.

The air expels the solids adhered to the filtering surface some distance away, so they are removed, but remain in the same medium (river, lake, reservoir, sea…), with no need for their collection or handling; they are normally drawn away by the current itself.

Cleaning may be performed manually or automatically, using a cyclic programmer that will perform the cleaning sequentially. The cleaning system is normally installed on dry land, on the banks and shores of rivers, lakes, reservoirs and the sea.

The minimal pressure drops, normally less than 20 cm of water column for a clean filter, and the energy costs during operation simply involve operating the compressor to fill the compressed air storage tank.

QUILTON passive intake screens are made of different qualities of stainless steels and special alloys, depending on the application.

Operation

Options in assembly and maintenance

- Numerous set-up options.

- Possibility of assembly with or without water.

- Control and regulation of cleaning sequences.

The correct operation of the passive intake screen requires leaving a free space of one diameter around the filter shaft and that same height should be the minimum water level. The pressure drop through the unobstructed QUILTON passive intake screen is less than 20 cm of water column.

ADVANTAGES OF THE PASSIVE INTAKE SCREEN

- High capture capacity.

- No solid waste management.

- Maximum suction speeds of 0.15 m/s through intakes.

- Noise output of cleaning system of less than 70 dB.

- No moving parts, and removeable covers.

- Ideal adaptation.

- Small size.

- Lifting lugs for handling.

- Low energy consumption.

- Low installation cost and minimal maintenance.

- Respect for the environment.

OTHER EQUIPMENT

Related equipment