This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

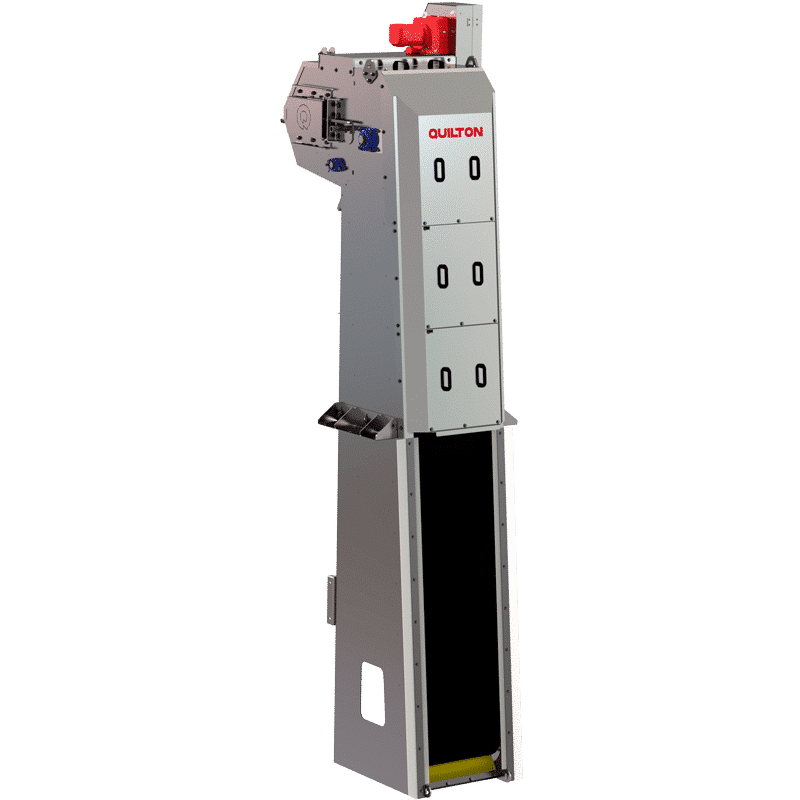

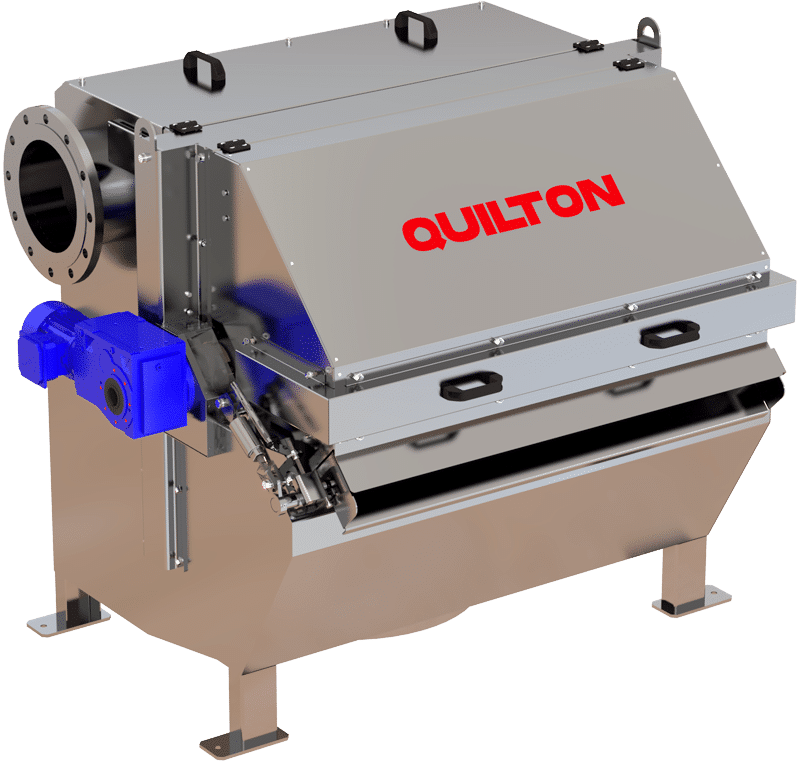

Storm overflow screen

Screens

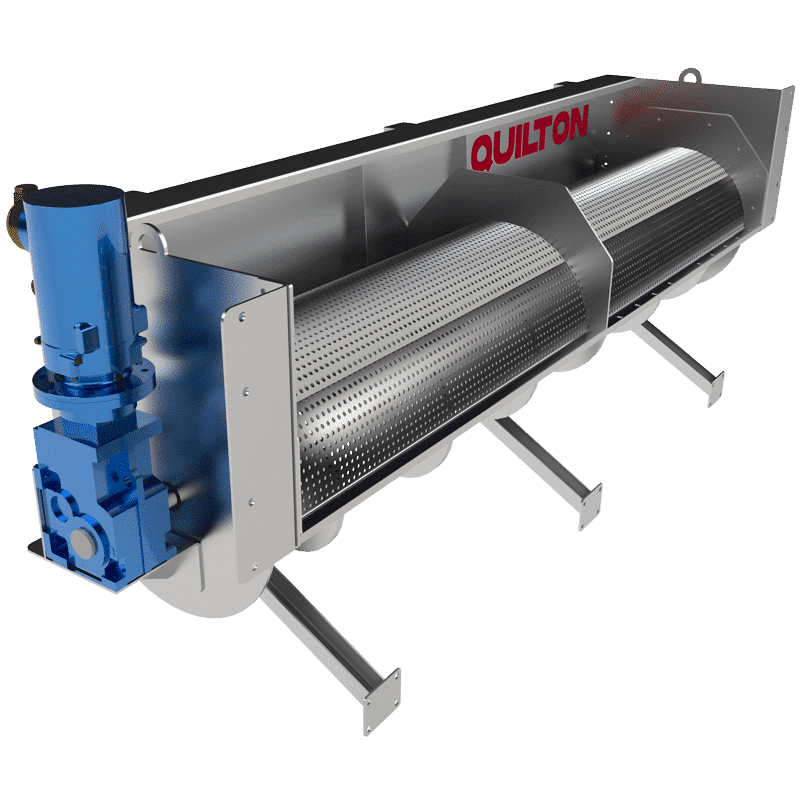

The QUILTON storm overflow screen is a device for retaining materials larger than 3-6 mm that are floating or suspended in a liquid overflow before being discharged into a river, lake or the sea. This tends to be due to an excess flow, generally during long episodes of rainfall or storms. The solids retained by the screen are drawn by the flow of water to a pumping station or WWTP for their subsequent treatment.

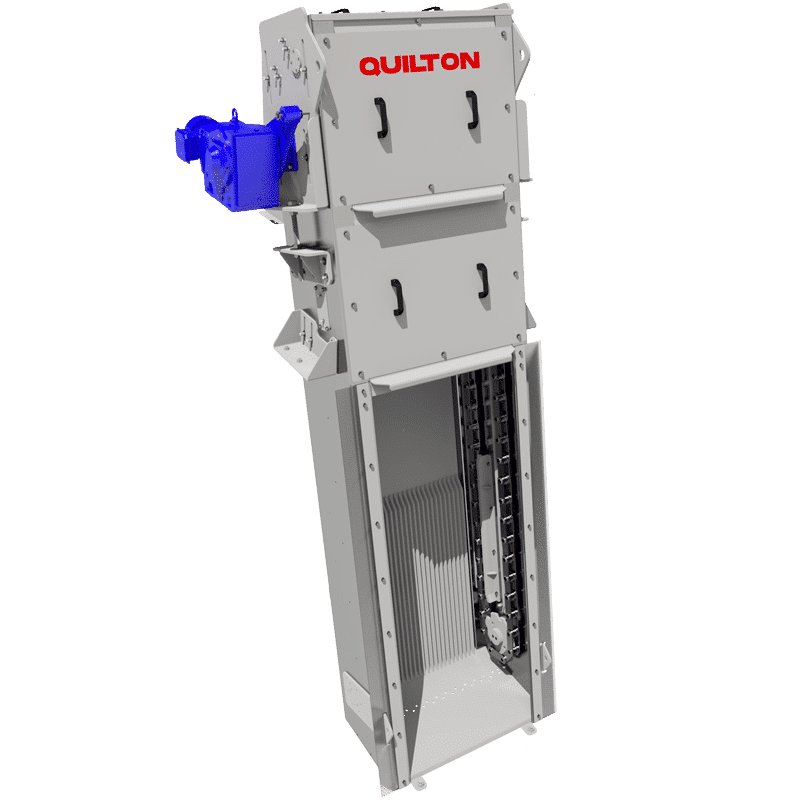

Its simple design, largely involving the slow movement of a spiral fitted with a cleaning brush and a static perforated plate, allows separating the wastes while continuously cleaning the screen. The electrical components in contact with the water have an IP-68 level of protection to ensure the installation operates in a due and proper manner.

Features and structure

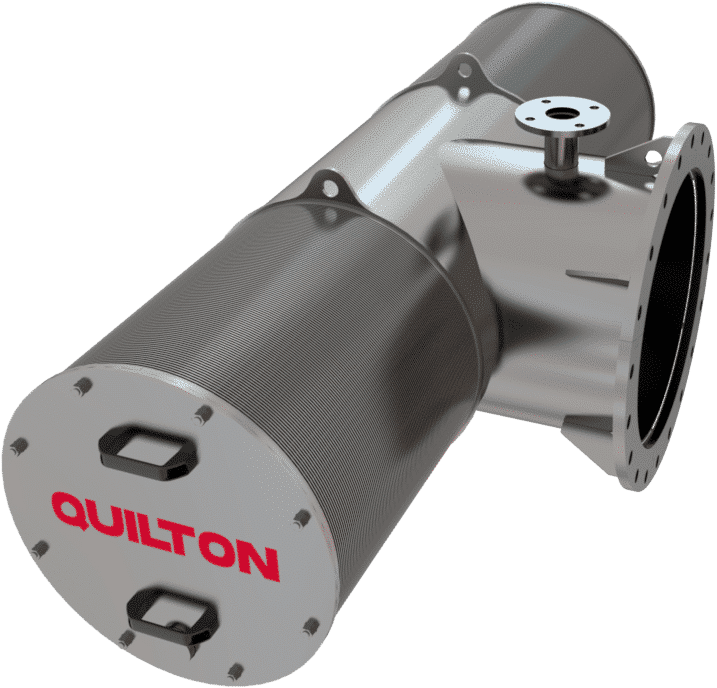

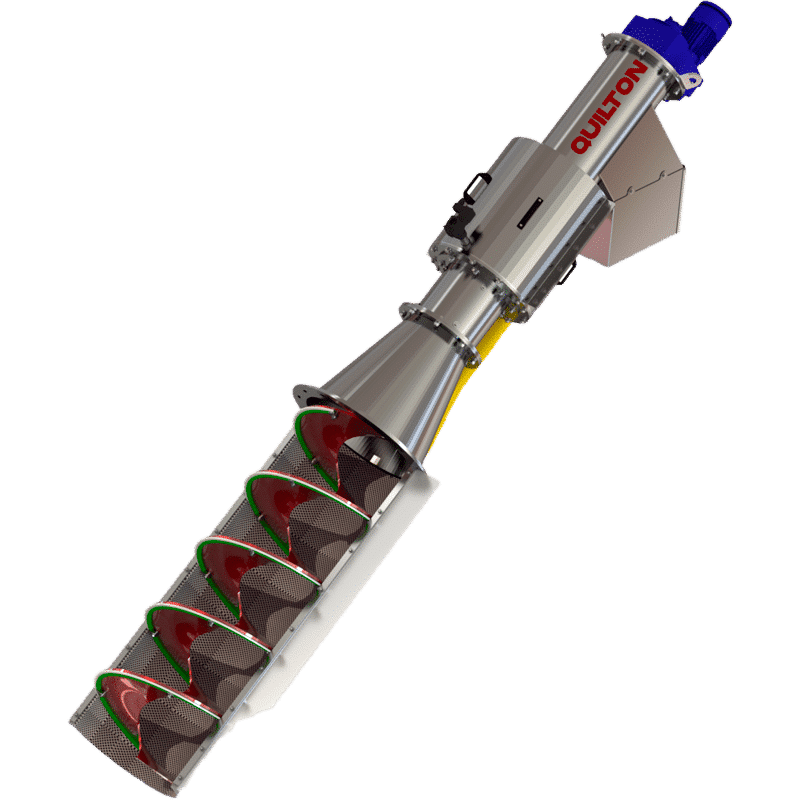

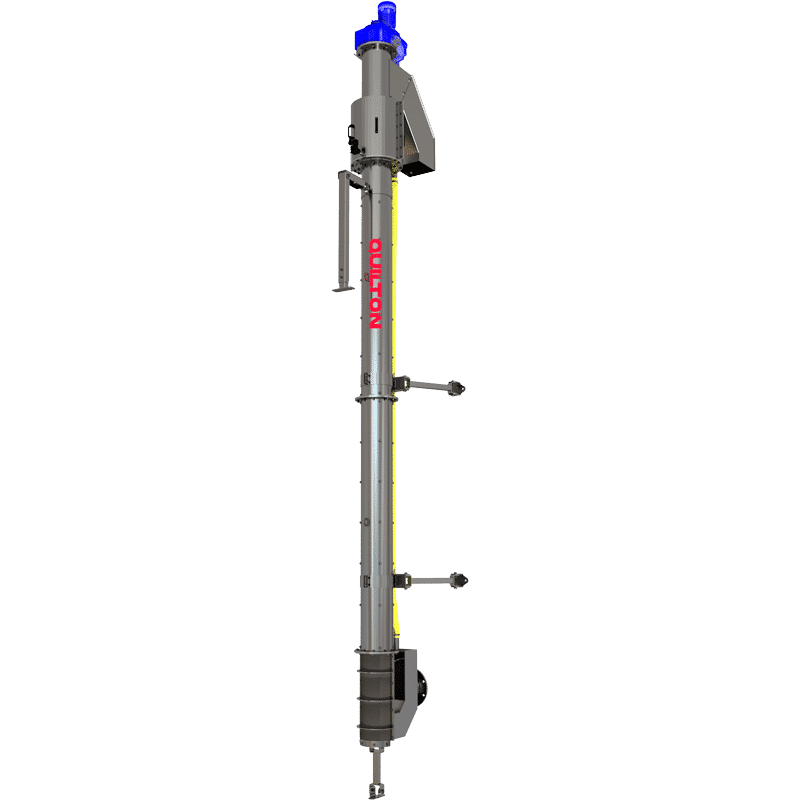

The QUILTON storm overflow screen is designed according to a modular system. All the models have the same elements, which are assembled according to the tasks required of the model requested. The diameter of the perforated cradle and its length means the equipment can be scaled according to the corresponding flow in each installation. The chassis structure is made up of rigid square tubes and folded steel-sheet profiles, whose purpose is to support the filtering cradle, the spiral, and the drive system.

The perforated chassis constitutes the screen’s filtering surface and may be made of different qualities of stainless steel (AISI 304L, AISI 316L, Duplex, Super duplex).

The space on the lattice is determined according to the holes drilled in the perforated steel section, with the most common ones being 3 and 6 mm, with an open surface equal to around 23-30%, respectively. The screen retains any solids floating in the water that are larger than the spacing on the lattice, and the spiral removes them, cleaning the filtering surface.

FEATURES

- The wastes are separated, and the cleaning of the storm overflow screen is carried out continuously thanks to the spiral’s slow forward movement and its cleaning brush.

- The design of the cleaning brush on the spiral guarantee that both its assembly and its attachment and removal are simple in maintenance operations.

- The solids retained are moved only when the forward direction is selected (same direction as the flow).

- All the components of the QUILTON storm overflow screen in contact with the water are made of stainless steel, except the motor, which has a special protection and IP-68 classification.

Operation

Thanks to the design of the filtering area, the spiral, and its brush, the screen is cleaned in the forward direction (moving in the same direction as the flow of water). In the event of episodes of clogging caused by large solids, the programming control allows reversing the direction of turn, changing to a backward movement, and after n repetitions of this operation the screen becomes unblocked and operational once again. In this way, floating solids are delivered to the WWTP by the actual current.

Other applications

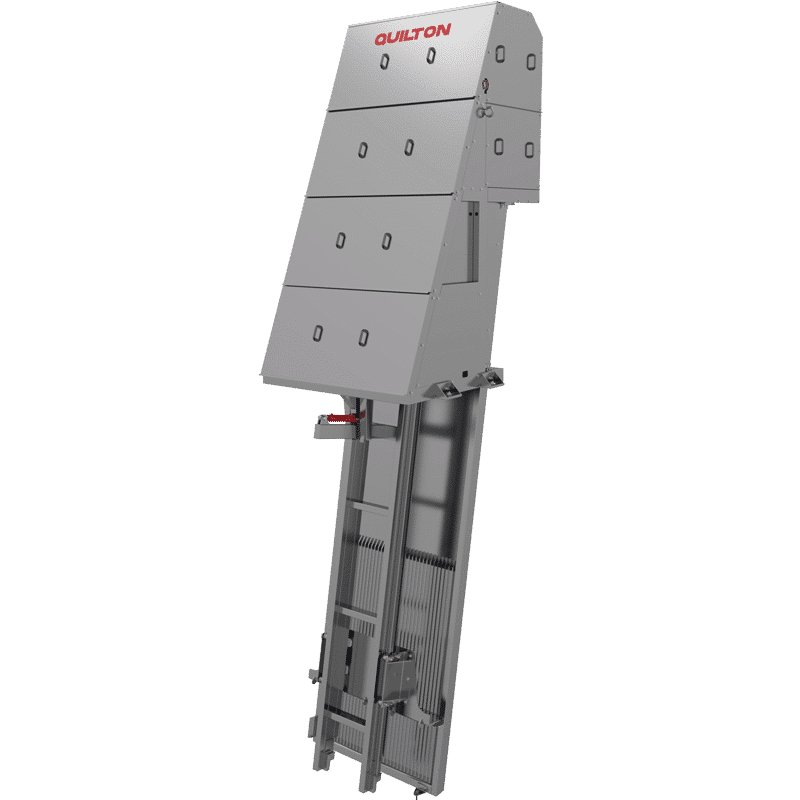

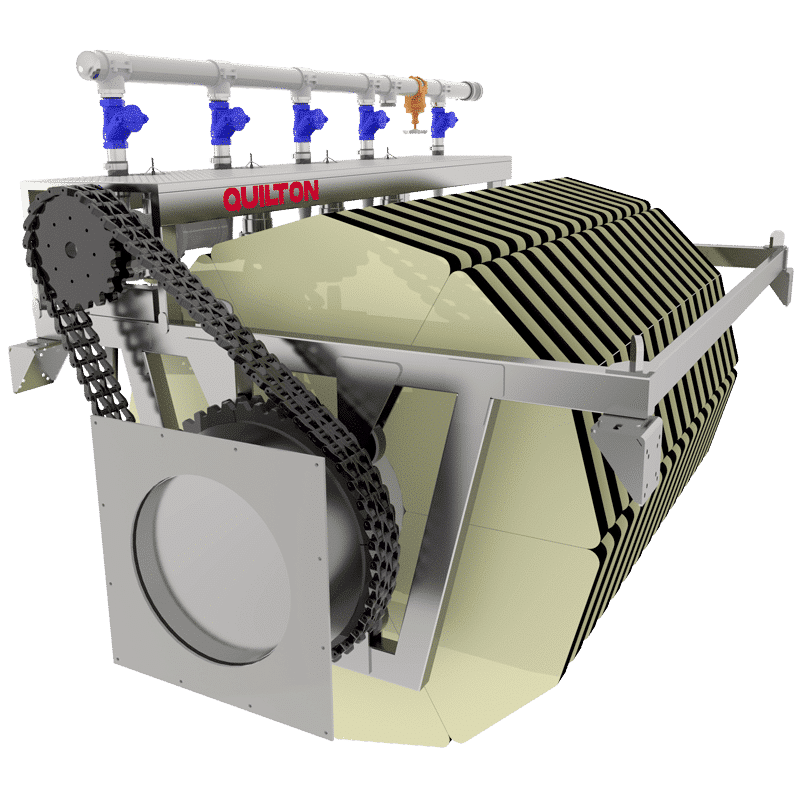

There are installations that involve dealing with large flows. In these cases, it might be expedient to include double-basket screens that also have a double spiral and brushes for self-cleaning, as in the following:

- Installations with short overflow channels.

- Installations with a high overflow rate.

- Installations with a high concentration of solids that require a large open area to uphold the flow of water.

ADVANTAGES OF THE STORM OVERFLOW SCREEN

- High operating safety.

- Solid and robust construction.

- Minimum maintenance.

- Protects the environmental against pollution.

- Automatic cleaning.

- Resistance to corrosion, as it is made of stainless steel AISI 316.

- Minimal pressure drop.

- Modular system, customisable to each customer’s requirements.

OTHER EQUIPMENT

Related equipment