This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

Cloth filters for tertiary treatment

Filters

The cloth filter is one of the most widely used filtering techniques for the tertiary treatment of urban and industrial wastewaters.

The use of special cloths means a high capacity for solid separation, combining the characteristics and advantages of surface filtering with those of depth filtering.

Features and structure

The QUILTON cloth filter has the following characteristics that make it the ideal option for the tertiary treatment of wastewaters:

- Stainless steel structure.

- “Pile” or “free-fibre” fabrics.

- Option of installation in a concrete tub or metal tank.

- High filtering performance.

- Depth filtering by gravity with limited pressure drop.

- Continuous filtering during the cleaning stage, with no need for back-up units.

- Fabric backwashing via a suction pump.

- Low volume of backwash water.

- Low maximum power absorbed.

Classification

There are various models of cloth filters for tertiary treatment:

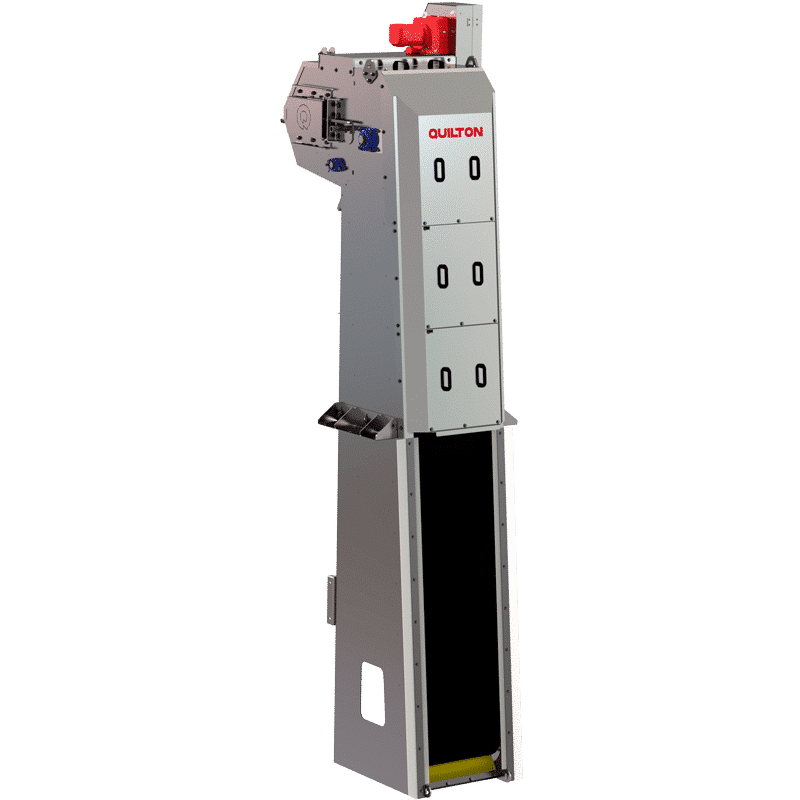

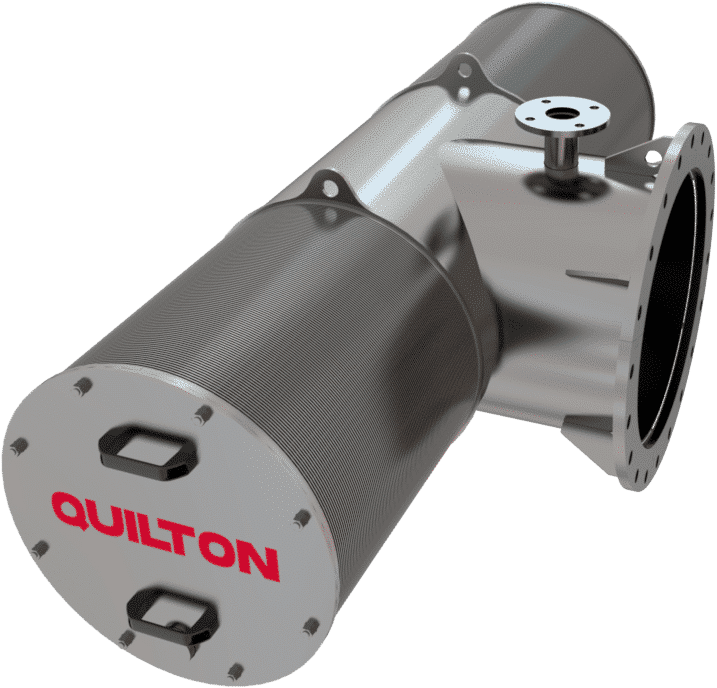

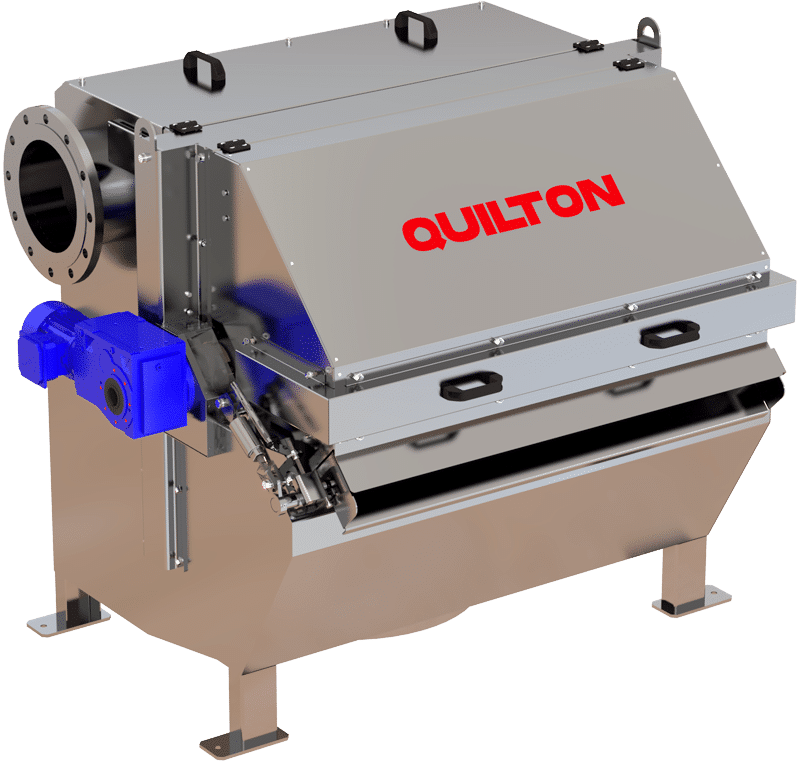

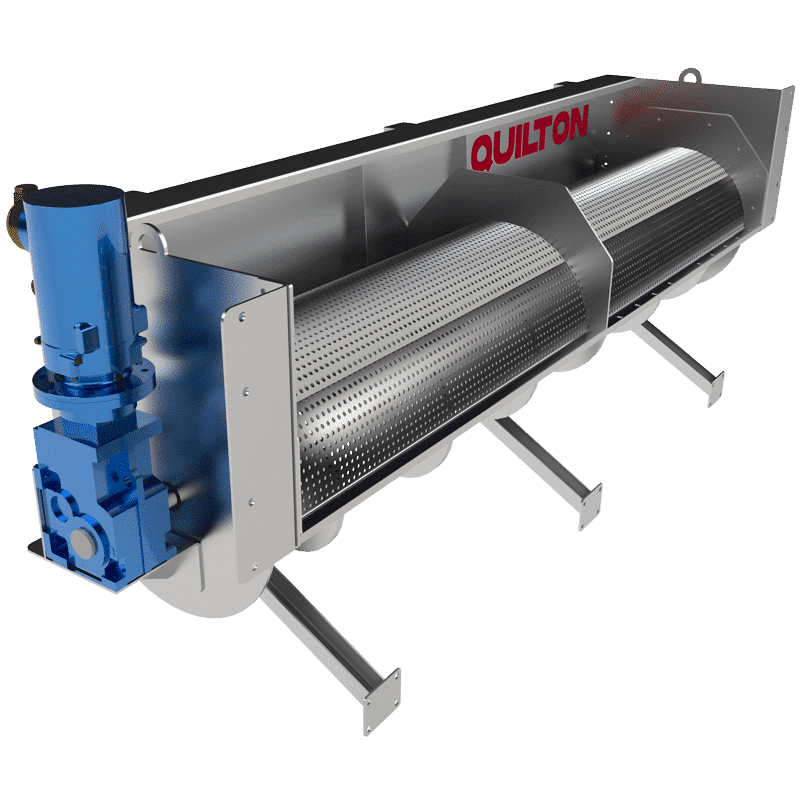

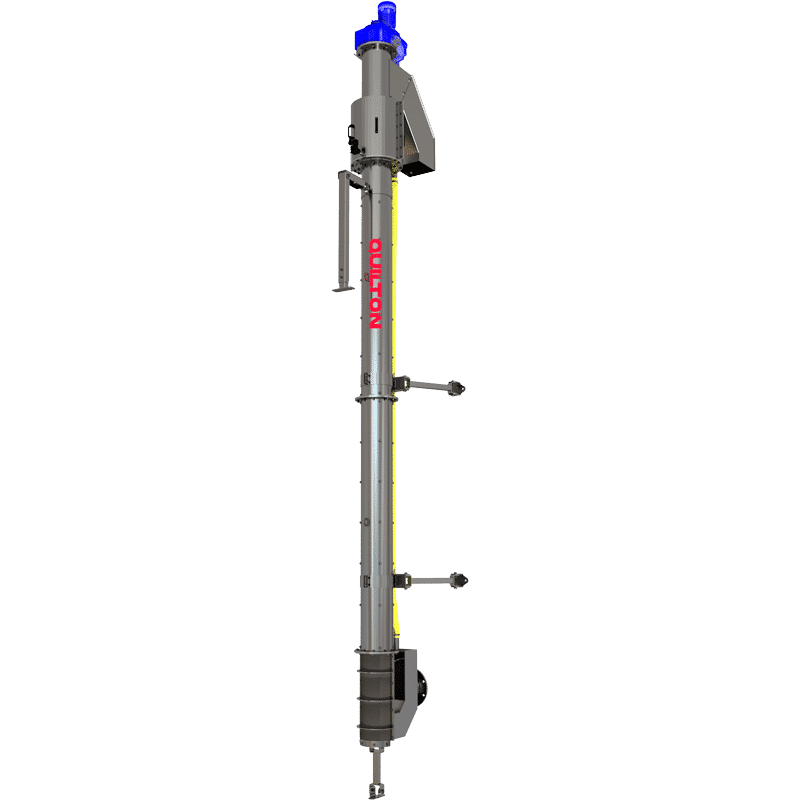

- Drum cloth filter: it consists of a perforated steel drum coated with a fabric of 2, 4 or 6 m2 of filtering surface, positioned horizontally and connected to a central shaft. This model of filter is used for low-capacity plants (up to a population equivalent of approximately 2,000).

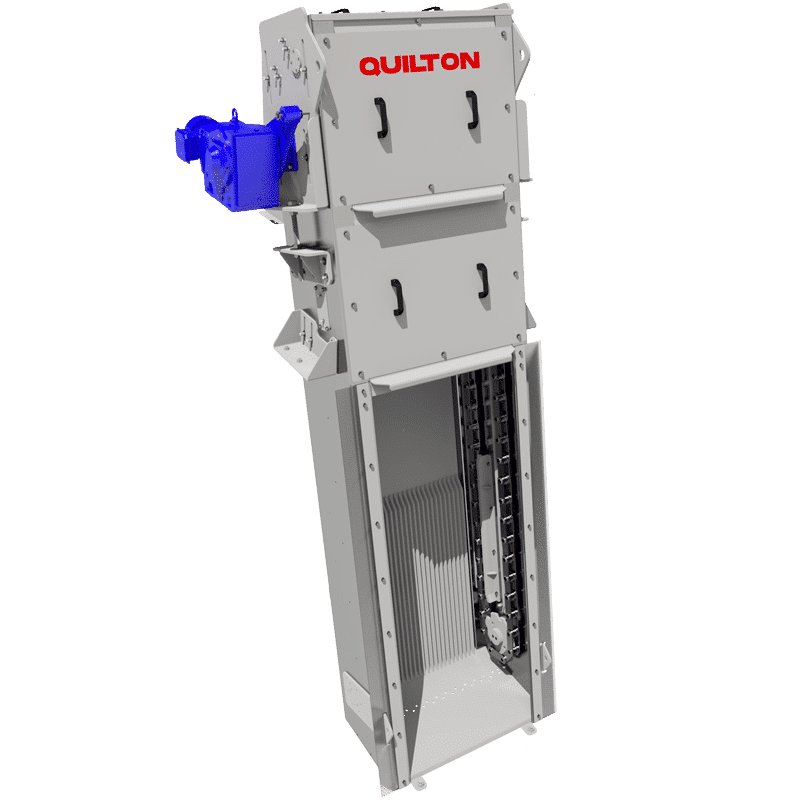

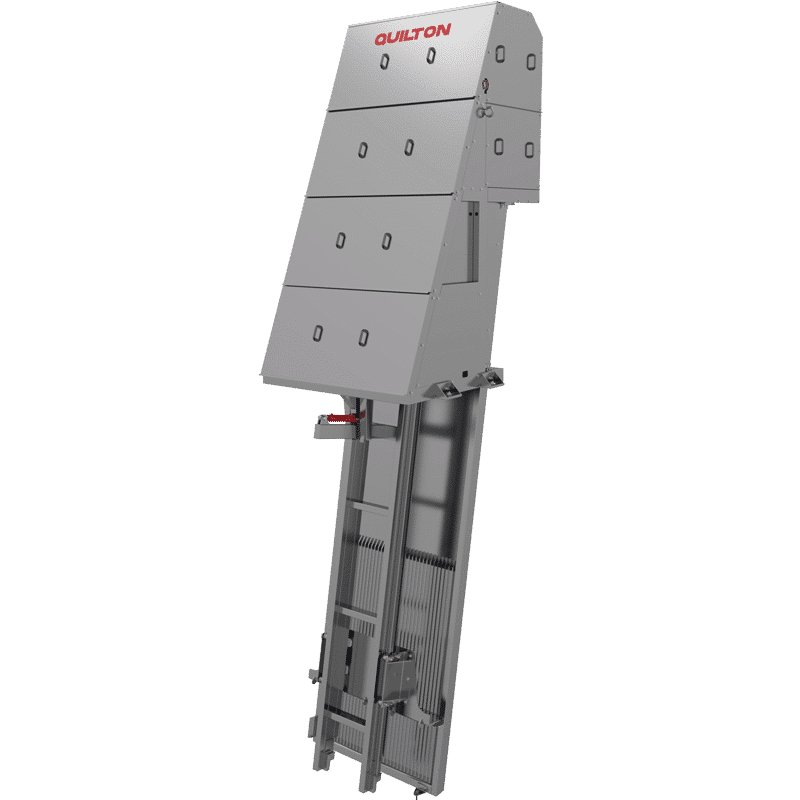

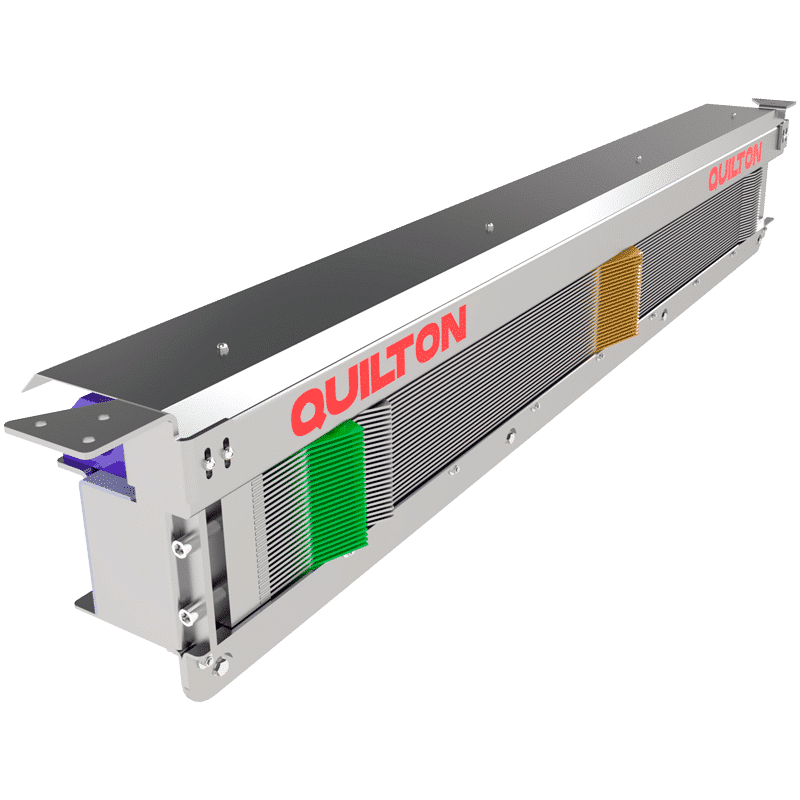

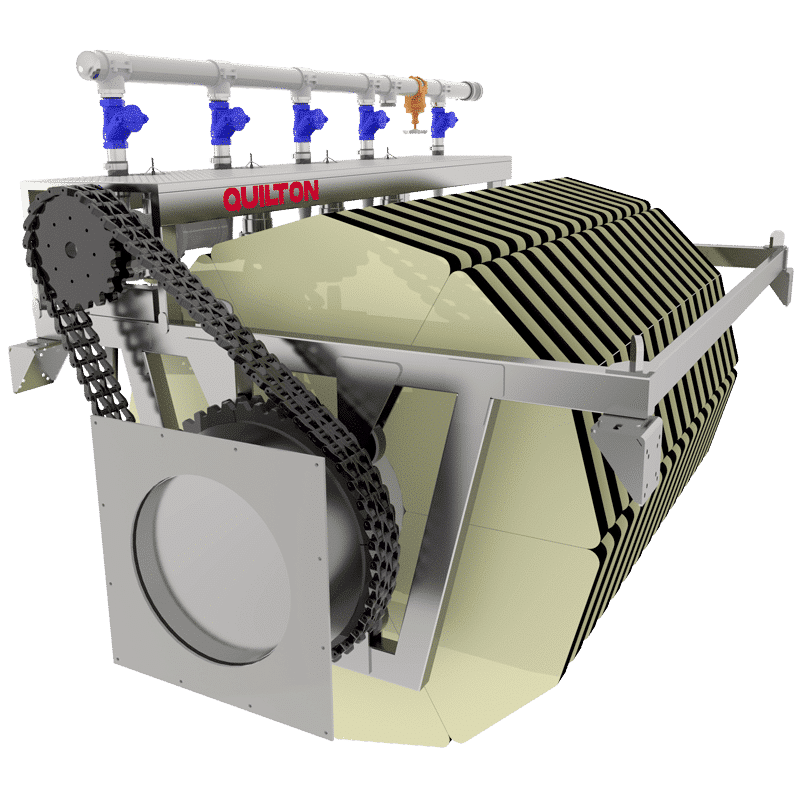

- Disc cloth filter: it involves a hollow central shaft that holds up to 32 discs, each one of which is made of six sections of plastic materials covered by a filtering cloth.

- PEC model: each group of four discs is hydraulically connected to its own cleaning system, whereby they are fully cleaned in a single complete rotation. This filter model is used for medium-sized plants (up to a population equivalent of approximately 20,000).

- PPC model: only two suction pumps are installed that operate alternately, one running and one in stand-by. This arrangement is used especially for plants with large flows (up to a population equivalent of approximately 50,000).

Filtering process

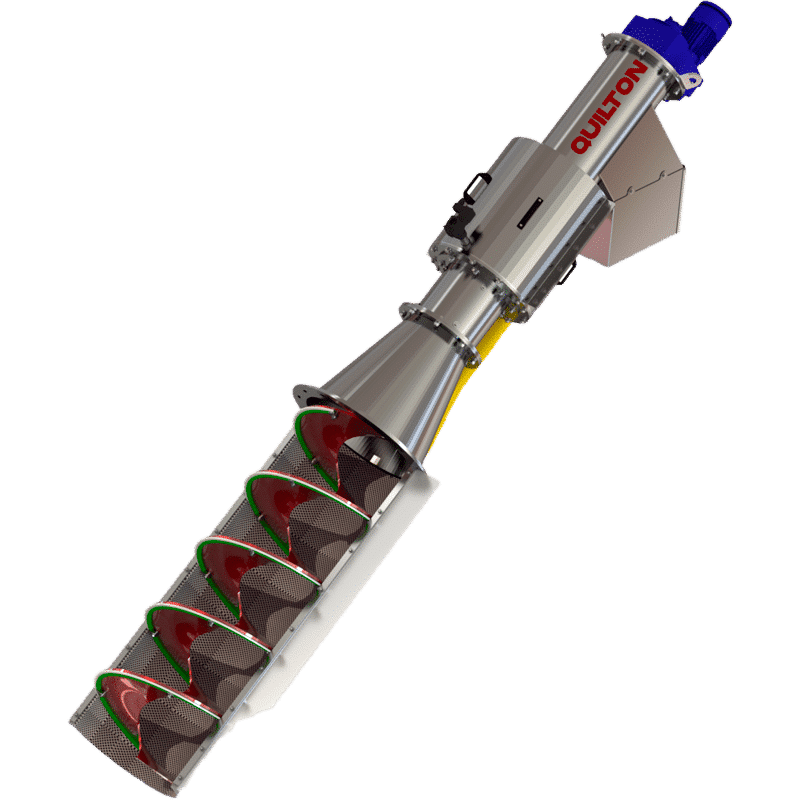

A cloth filter operates by gravity, with the equipment fully submerged. When the quantity of solids on the filtering cloth builds up, it triggers a cleaning system. During this automatic backwash, the drum or the discs, which have their own suction-based cleaning devices, are fully cleaned in a single full rotation.

The fabric used is “Pile” or “free fibres”. During the filtering stage, these fibres are flattened, pushed out of shape, and interweave to form a highly efficient panel for separating and retaining solids in suspension. During the cleaning stage, the fibres stretch within the suction device and the solids previously retained are removed by the flow of the backwash water. This filtering technique allows for the use of slender fibres and records an optimum separating performance, even in the case of high hydraulic pressures with minimum cleaning flows.

PROCESS DESCRIPTION

The drum or discs are rotated for cleaning by a motor. The system is also equipped with a submerged pump for removing sludges, which means the tub can be drained whenever necessary. This pump is operated by a timer, but it is never activated when the backwash is taking place. This allows reducing the maximum power used by the machine, which in the worst of cases is that required for operating the gear motor on the filter and a suction pump.

The cleaning of the cloth does not require a back-up unit or a water supply, as the drum or discs being cleaned are partially filtering at the same time. The cleaning water together with the solids retained and the sludge removed from the bottom of the tub return to the head of the plant.

ADVANTAGES OF THE CLOTH FILTER FOR TERTIARY TREATMENT

- Minimum design requirements.

- Simple installation. Flexible adjustment to existing plants.

- Minimal maintenance and direct access to all filter parts.

- Reduced environmental impact.

- Low power and energy consumption.

- No generation of aerosols or acoustic pollution.

- No need for regular washing with chemical products.

USES OF THE CLOTH FILTER FOR TERTIARY TREATMENT

- Separation of solids in suspension at the outlet of secondary decantation tanks.

- Reduction in phosphorous content at the outlet of WWTPs.

- Prefiltering at the inlet to the UV disinfection process, which means less disinfection power is required.

- Separation of solids after the physicochemical treatment of an industrial effluent.

- Separation of excess sludge after the biological treatment.

- Prefiltering at the inlet to the nitrification process.

- Prefiltering at the inlet to membrane process.

- Prefiltering of the surface water destined for drinking water.

- Removal BOD5.

- Removal of microplastics.

- Reuse of wastewater.

OTHER EQUIPMENT

Related equipment